Automation systems have long become a necessary foundation for driving smooth and profitable production. It’s difficult to imagine a medium-sized or large enterprise without a system for planning and controlling production processes, tying up workflows of different departments, and coordinating a single data flow. The article will give an example of a successful Odoo implementation using an open-source, modular ERP system to streamline production.

The pain

A prominent manufacturer of spare parts for the automotive industry approached us with the need to implement an efficient, up-to-date business automation system.

The main goals were to minimize production defects by automating the whole process, from receiving an order to shipping the final product to the client, while tracking each aspect and defining the most time-costly processes for further optimization. All tasks were required to be monitored in real time, with results assessed afterward to identify equipment downtime and total time loss.

It was crucial for all divisions to get a unified data management structure and the ability to communicate internally and collaborate on documents.

The solution

The open-source Odoo ERP system was chosen as the main tool to solve the task, with some tailored customizations added.

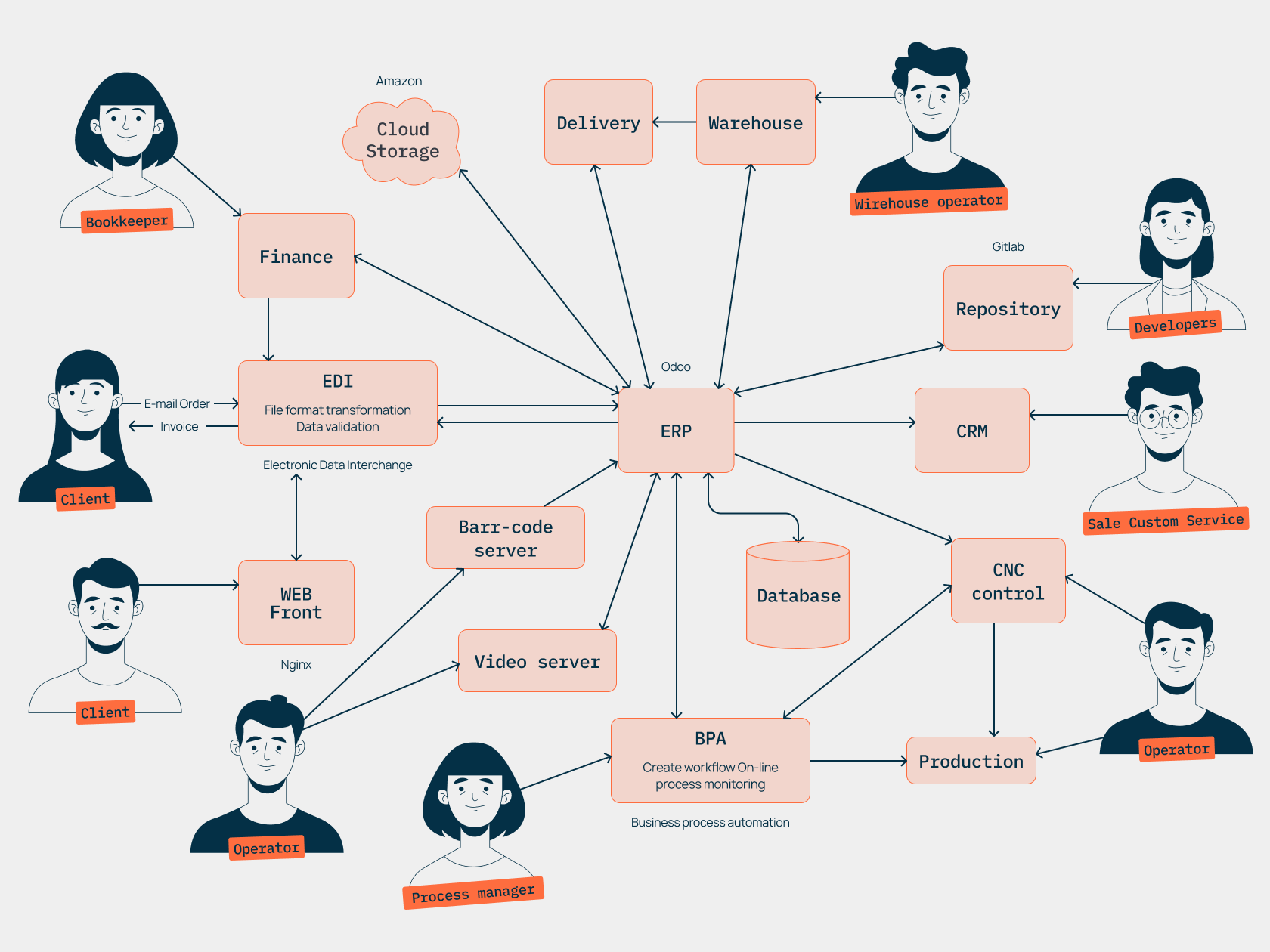

The system was expanded with extra features dedicated to EDI (Electronic Data Interchange) and BPA (Business Process Automation). The IDE was necessary to receive orders in various forms, e.g., through emails with different file type attachments, such as PDF and Docx, as well as validate required fields. The received data is converted into an XML document and then sent to the ERP. The BPMN 2.0 business process modeling standard was used to design a BPA flow.

We implemented several ways personnel can interact with the system.

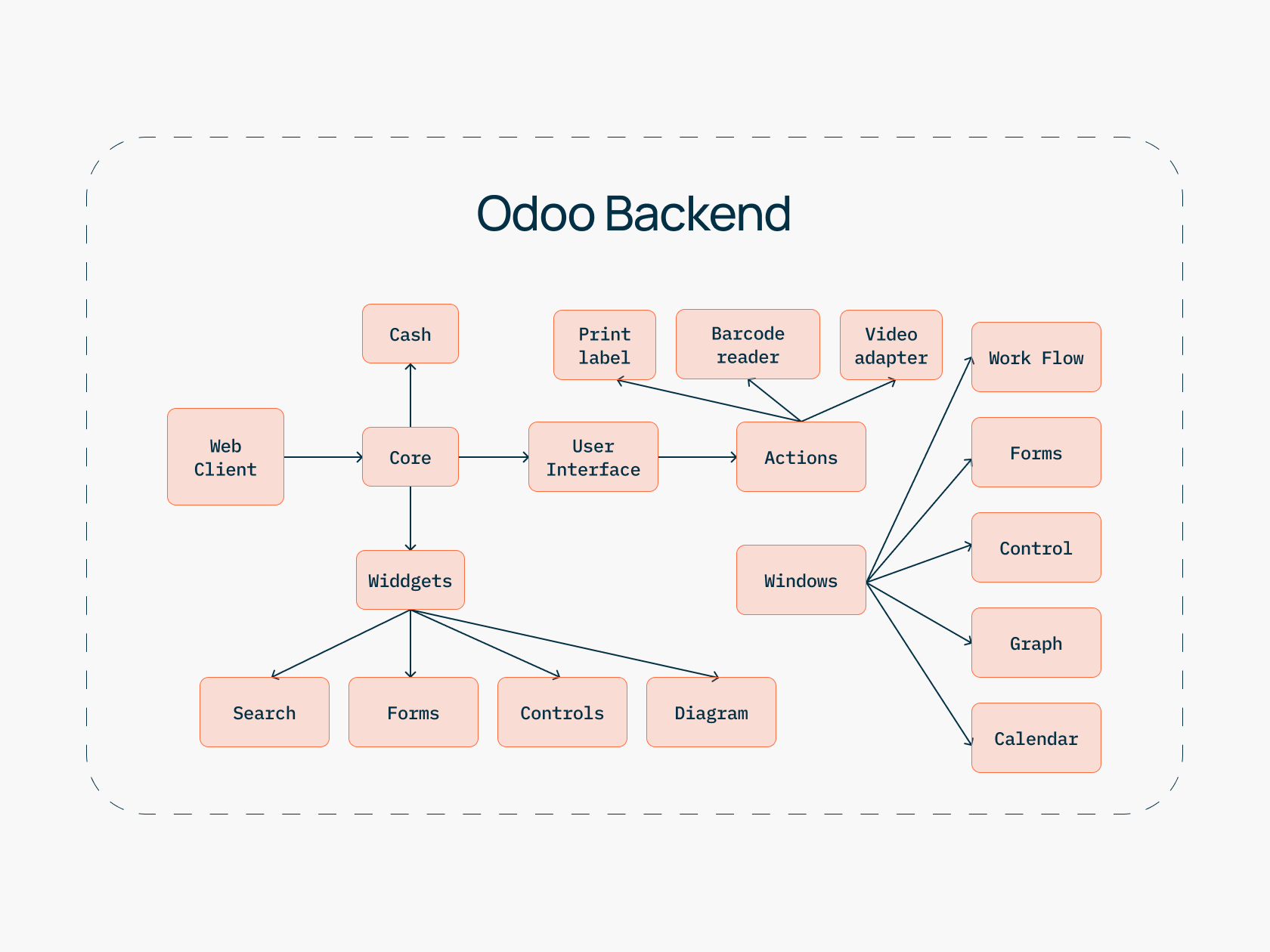

- Odoo's Frontend Web Forms is the first option, fitting employees working behind the desk.

- A mobile application — Odoo Frontend can only perform natively, providing a full scope of features for workers without a fixed work location.

- Barcode scanning — both mobile applications and physical scanners can be used for scanning in the warehouse or during the supply chain transfer.

Implementing barcode scanning, we ran into an issue of some products missing the barcode marking, which was solved with the help of photo capture. Here’s how it works:

- An employee, such as a turner, photographs the finished product.

- Their task is deemed fulfilled after the photo is validated in the order.

- After receiving the item, the next specialist responsible for other parts of the product also takes pictures of it at the start and finish of the production.

Specialized Odoo ERP modules helped us to also introduce an efficient document circulation system for storing, processing, and sharing account data, orders, invoices, and bills of landing. This added up to the error-free, automated performance. With the convenient connection to bank accounts, production materials can be paid for automatically, and financial flows can be controlled autonomously.

On top of that, the implementation of the connected CRM system has enabled fast communication with customers and suppliers, as well as automatic completion of all relevant documents.

The use case diagram for the solution is shown in the figure below:

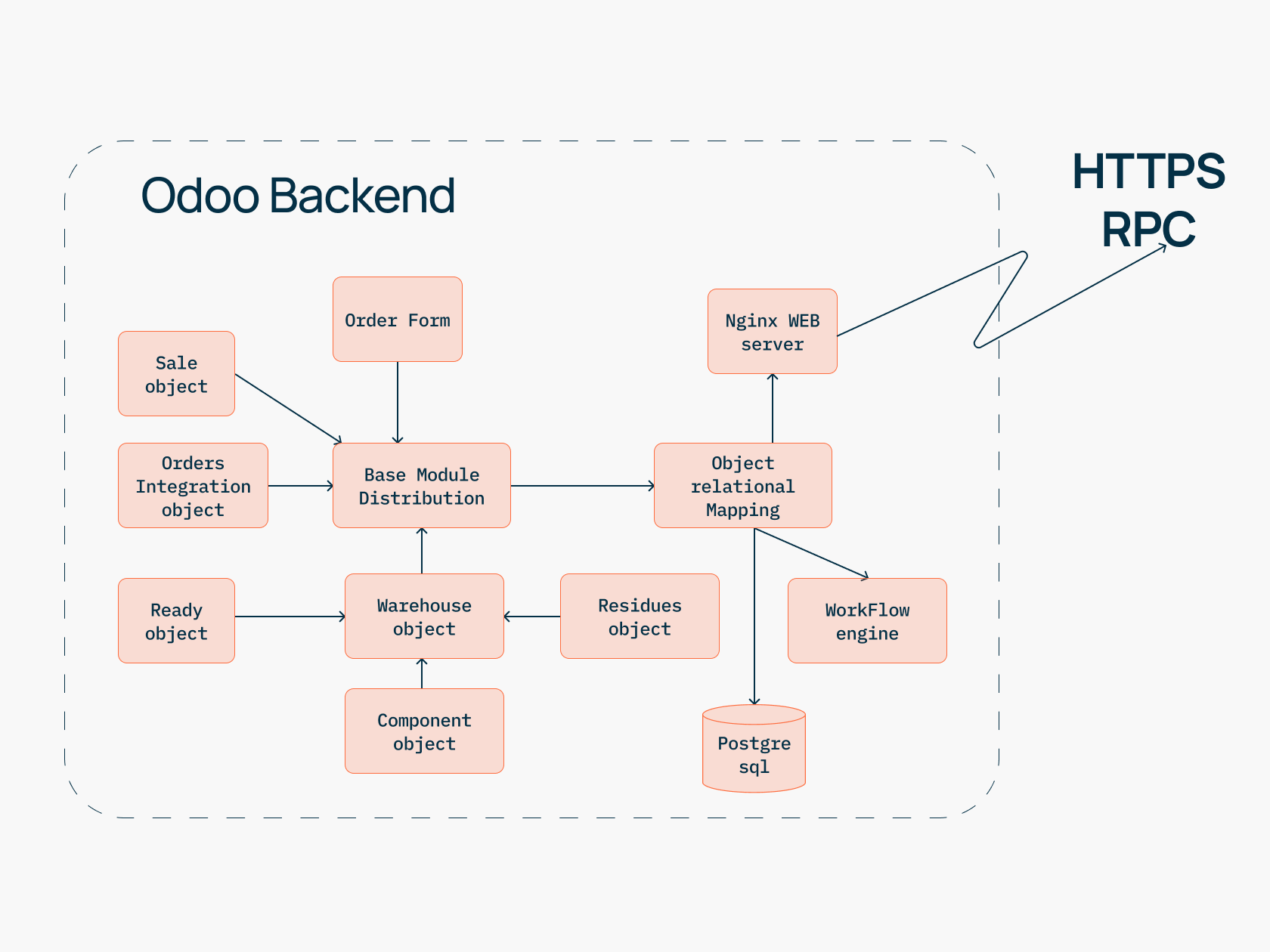

We used Amazon S3 buckets in order to grant reliable and safe data storage, setting the system off into operation on the enterprise's internal servers. The internal database was powered by PostgreSQL.

The implementation of the Odoo Backend looks took place as follows:

Communication between the Backend and the Frontend computer was established via HTTPS, and communication with the native mobile application was set up with gRPC queries.

Cloud storage was employed to archive data and grant scaling with load balancing based on Nginx and Odoo server replication.

The front end system of the custom Odoo ERP software is presented below:

The same implementation scheme was employed for mobile and web applications. The CI/CD system is based on the Bitbucket and Gitlab repositories. After committing to the Gitlab repository, Bitbucket creates Docker containers. After successfully passing smoke tests, the release artifact is produced.

Technologies used

The following technologies were used in the development process:

Programming languages:

- Python

- Node.JS

- Bash

- Flutter

Communication:

- gRPC

- REST

- TFTP

CI/CD:

- Gitlab

- Jenkins

- Docker

Results and future plans

At the moment, the system operates in the enterprise’s normal mode, with up to 300 internal users. With load balancing between copies of Odoo servers, the system can scale to handle up to thousands of users. End-to-end data exchange is achieved by syncing up all departments of the enterprise.

Production processes can be thoroughly monitored online. There is also an analyst for a selected period of time. All in all, the introduction of the system powered by the Odoo ERP solution has increased the client’s production performance by over 25%. All thanks to careful downtime optimization and hardware reconfiguration with the minimization of the number of rejects in mind.

The main functionality of the system includes:

- Collaborative work on company documents

- Financial applications

- A system that controls the flow of products automatically

- The inventory of finished products and materials required for their manufacture

- Cross-check documentation with the employer and subcontractors

- CRM client management system

The system was developed over a year and a half by dedicated Odoo ERP developers, and there will be a second phase focused on warehouse analysis and forecasting.