Every time a device in your digital system, whether it's used to detect defects or move inventory in a warehouse, needs to make a decision, it sends a request to a remote server. At this moment, even a split-second latency can lead to a crash, while unstable Wi-Fi can halt workflow. If you add to this the ever-increasing cloud vendors’ bills and the potential privacy risks of your data when it's transferred to the cloud, it becomes clear that alternative options are needed. Actually, that's why we decided to dedicate this article to answering the question: “What is embedded AI?”

What Is Embedded AI?

So, let’s start with an embedded AI definition. In a nutshell, it is a technology for deploying AI directly on microcontrollers or processors within devices. Unlike traditional AI, which requires powerful server-side GPUs, embedded AI operates locally, transforming ordinary sensors, cameras, machines, and other edge devices into highly intelligent units capable of analyzing data autonomously and making decisions locally.

Indeed, given the growing need for autonomous systems, as well as the constant expansion of connected device ecosystems and the Internet of Things, it becomes clear why the embedded AI market is growing so rapidly: according to statistics, it will reach $21,930.4 million by 2030, with a CAGR of 14.1%.

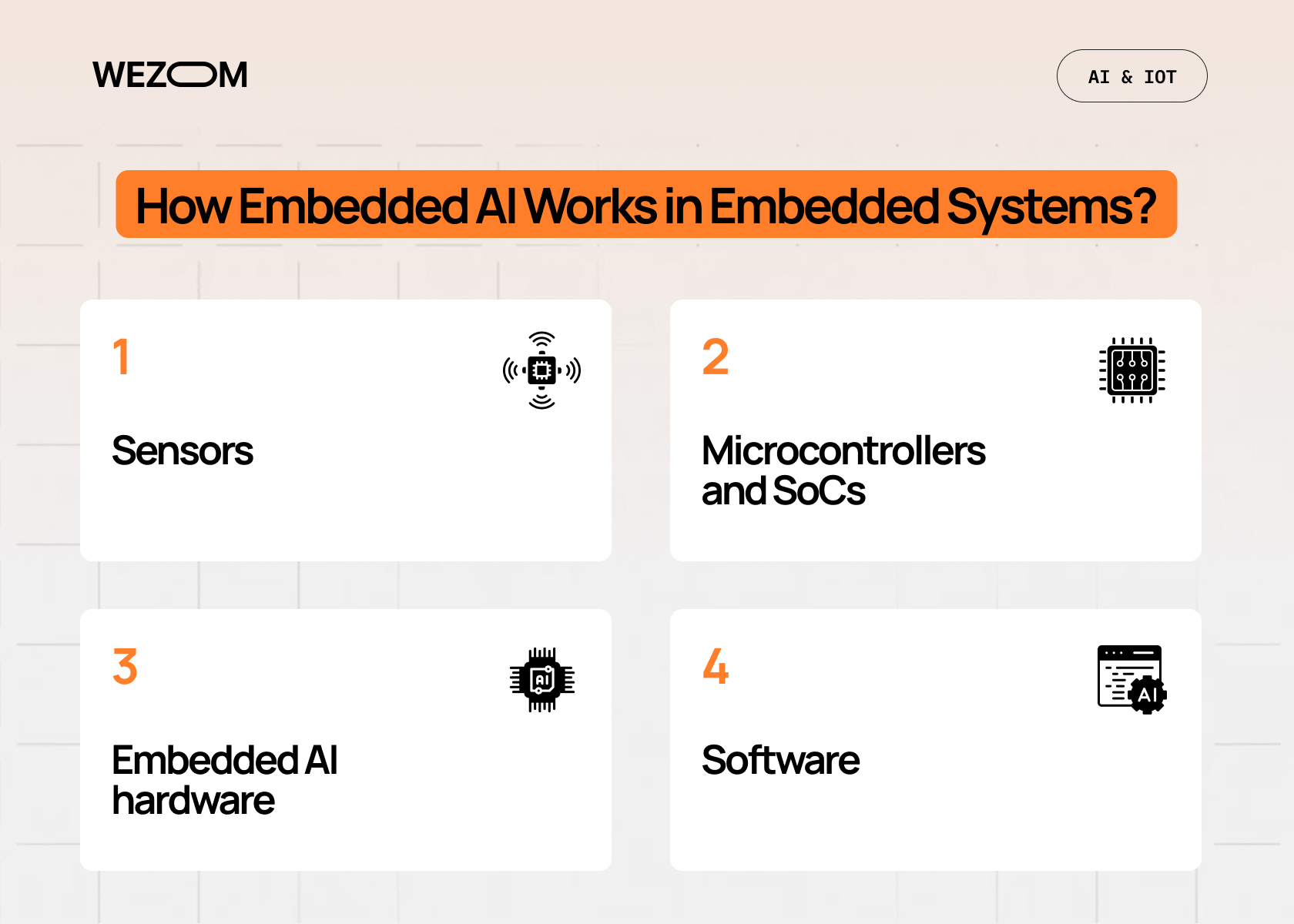

How Embedded AI Works in Embedded Systems?

Let's consider all the components of embedded AI in detail to understand how such systems are implemented.

- Sensors. These include temperature and pressure sensors, accelerometers, video cameras, and other highly specialized devices that collect raw data from physical environments and record changes instead of transmitting this information to the cloud.

- Microcontrollers and SoCs. These solutions utilize both classic microcontrollers like the ARM Cortex-M and more powerful SoCs. The main requirement is maximum performance with minimal power consumption (in practice, such devices can operate for months on a single battery).

- Embedded AI hardware. For tasks requiring high execution speed, specialized neural processors or tensor accelerators are used. These are compact chips whose architecture is tailored for neural network mathematical operations, enabling their execution tens of times faster than conventional processors.

- Software. The software component requires the use of highly optimized libraries and frameworks such as TensorFlow Lite or TinyML – they allow the neural network to fit the device's limited memory without compromising the accuracy of its inferences.

It's also worth noting that the data flow in embedded AI systems is implemented in a unique way: it begins with signal capture by the sensor, after which the data undergoes a preprocessing stage (noise removal and normalization) on the device itself. The AI model then performs inference, transforming it into a specific action, whether it’s a command to stop the engine, an alarm, a notification about a worn or defective component, or something else. It’s important to note that the data doesn’t leave the device's perimeter, thereby ensuring an immediate response and absolute information security.

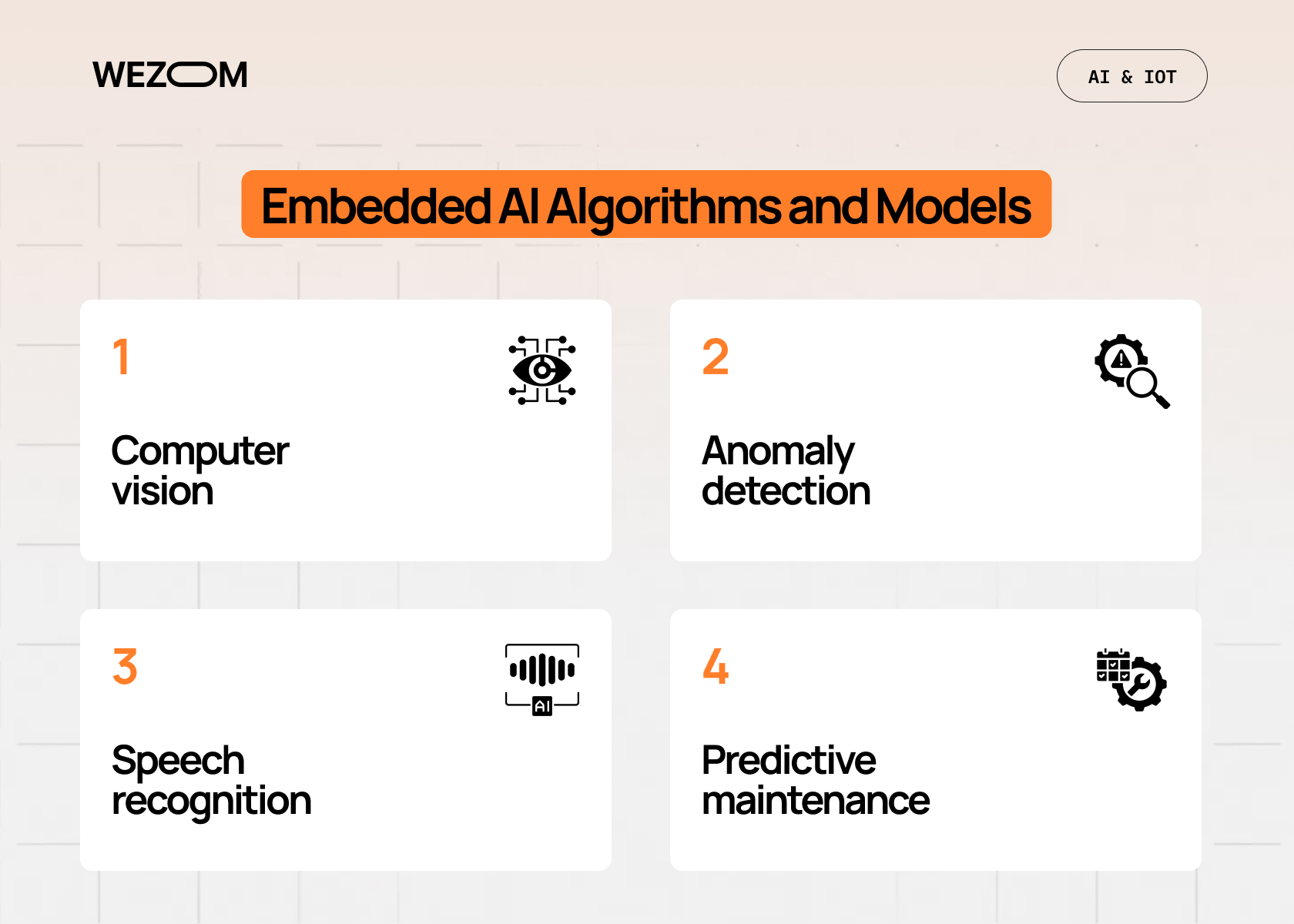

Embedded AI Algorithms and Models

The choice of an embedded edge AI algorithm depends on the limitations of specific devices and the tasks assigned to them.

- Computer vision. These algorithms allow devices to see – for example, through quality control cameras on a production line that automatically filter out defective items, or through onboard cameras monitoring driver fatigue that analyze head tilt and blink rate.

- Anomaly detection. These algorithms are trained on data about the normal operation of physical systems (for example, they can learn to recognize the sound of a normally operating turbine or the current in an electrical grid) and notify if any deviation from the norm occurs, thereby preventing breakdowns before they are noticed by a human technician.

- Speech recognition. AI for embedded systems makes it possible to implement voice control without the need to send audio files to the cloud, which may be the only viable option for medical devices or smart home systems where user privacy is a priority.

- Predictive maintenance. Using data from vibration and temperature sensors, embedded AI predicts the remaining life of equipment. This is how predictive maintenance is implemented, to eliminate unnecessary downtime and save on spare parts that could still be used.

At the same time, to enable AI to run on a fingernail-sized chip, the model must undergo optimization, which includes quantization (reducing the precision of neural network weights to reduce memory footprint and speed up computations with a loss of prediction accuracy of less than 1%), pruning (trimming redundant connections in the neural network so that the model can run on the most budget microcontrollers), and model compression (using more compact layers and replacing resource-intensive operations with their lightweight alternatives to get a model that takes up kilobytes instead of megabytes).

Embedded AI Applications by Industry

Intelligence installed directly on equipment enables automation of processes that previously required constant human attention. This applies in particular to the following industries.

Manufacturing

In Manufacturing 4.0, embedded AI typically takes the form of systems based on smart sensors attached to machines. This enables real-time vibration and thermal profile analysis, predicting failure weeks before it occurs. It can also involve cameras installed on conveyors that detect microdefects invisible to the human eye, and which operate at a speed of thousands of units per minute.

Automotive

Driver assistance systems, also known as ADAS, use embedded AI for emergency braking and lane keeping when delays in data transfer via the cloud are unacceptable. Neural networks also find applications directly in vehicle cabins, for example, to monitor driver efficiency by recognizing signs of drowsiness or distraction. In this way, they can save lives and minimize insurance risks for fleets on the road.

Healthcare

Wearable gadgets like smartwatches and Holter monitors equipped with embedded AI can perform the diagnostics of arrhythmia, apnea, or any other disease affecting breathing, pulse, or blood pressure, directly on the patient's wrist. As for portable diagnostic devices like handheld ultrasound scanners, AI helps doctors in the field accurately interpret medical images, detecting any abnormalities. This ensures the privacy of medical data through analysis performed locally on the specific device.

Smart homes and consumer IoT

In smart homes, embedded AI allows security cameras to distinguish between the tree branches and human movements, while smart thermostats become capable of learning residents' habits without the need to send their life histories to corporate servers. Voice control can also become instant, as commands are now processed by a microcontroller on the device, rather than in a remote data center.

Logistics and retail

In retail, embedded AI can be implemented in smart shelves, which, thanks to their autonomy, monitor product availability and prevent theft. In logistics, this technology will find application in the implementation of intelligent cargo trackers that analyze transportation conditions and automatically trigger an alarm if fragile goods are exposed to strong vibration or unacceptable temperature conditions.

Industrial automation

Robotic manipulators and warehouse robots most often use embedded AI for local navigation and safe interaction with people. This allows them to instantly reroute when an obstacle appears, without waiting for a response from the central warehouse management system.

Real-World Embedded AI Use Cases

In this paragraph, we invite you to explore several embedded AI examples implemented by global corporations – we’ll explain how using embedded AI helps to solve specific problems.

Case 1: Bosch SoundSee on the ISS and in the industry sector

This system was designed to solve a fundamental problem: detecting faults in complex equipment by ear. Previously, this required the presence of an experienced engineer, which is impossible in space or on remote, autonomous installations. As a solution, Bosch developed the SoundSee system, which uses embedded AI to perform the analysis and classification of surrounding audio signals. Deep learning models run directly on the device, listening to machine noise and identifying anomalies in sound patterns that indicate bearing wear or leaks.

This solution has been refined to predict faults with over 90% accuracy without human intervention. Thus, industry now has a powerful acoustic predictive maintenance tool, eliminating costly, unexpected downtime.

Case 2: Tesla and the Full Self-Driving chip

Since a car's autopilot must make decisions in milliseconds, transmitting data from multiple onboard cameras to the cloud for processing would create fatal latency and require colossal bandwidth. To address this, Tesla developed its own FSD chip with a neural network accelerator, which enables video stream processing, object segmentation, and trajectory planning directly in the car. This chip is optimized for high-speed operation with limited power consumption.

As a result, Tesla has created the most advanced driver assistance system on the mass market – the independence of their autopilot from the internet guarantees safe operation even in tunnels or areas with poor network coverage.

Case 3: Rolls-Royce’s predictive engine maintenance

Because aircraft engines generate terabytes of data per flight, analyzing it in real time via satellite communications is either prohibitively expensive or impossible at all. To overcome this challenge, Rolls-Royce developed its proprietary IntelligentEngine platform. AI modules embedded in this engine process data from thousands of sensors locally, detecting microscopic deviations in operating cycles and transmitting only reports and critical alerts to the cloud.

Thanks to widespread implementation, airlines worldwide are now saving millions of dollars on fuel and maintenance. Their engines can also inform ground crews which spare parts need to be prepared for landing, thereby minimizing aircraft time on the ground.

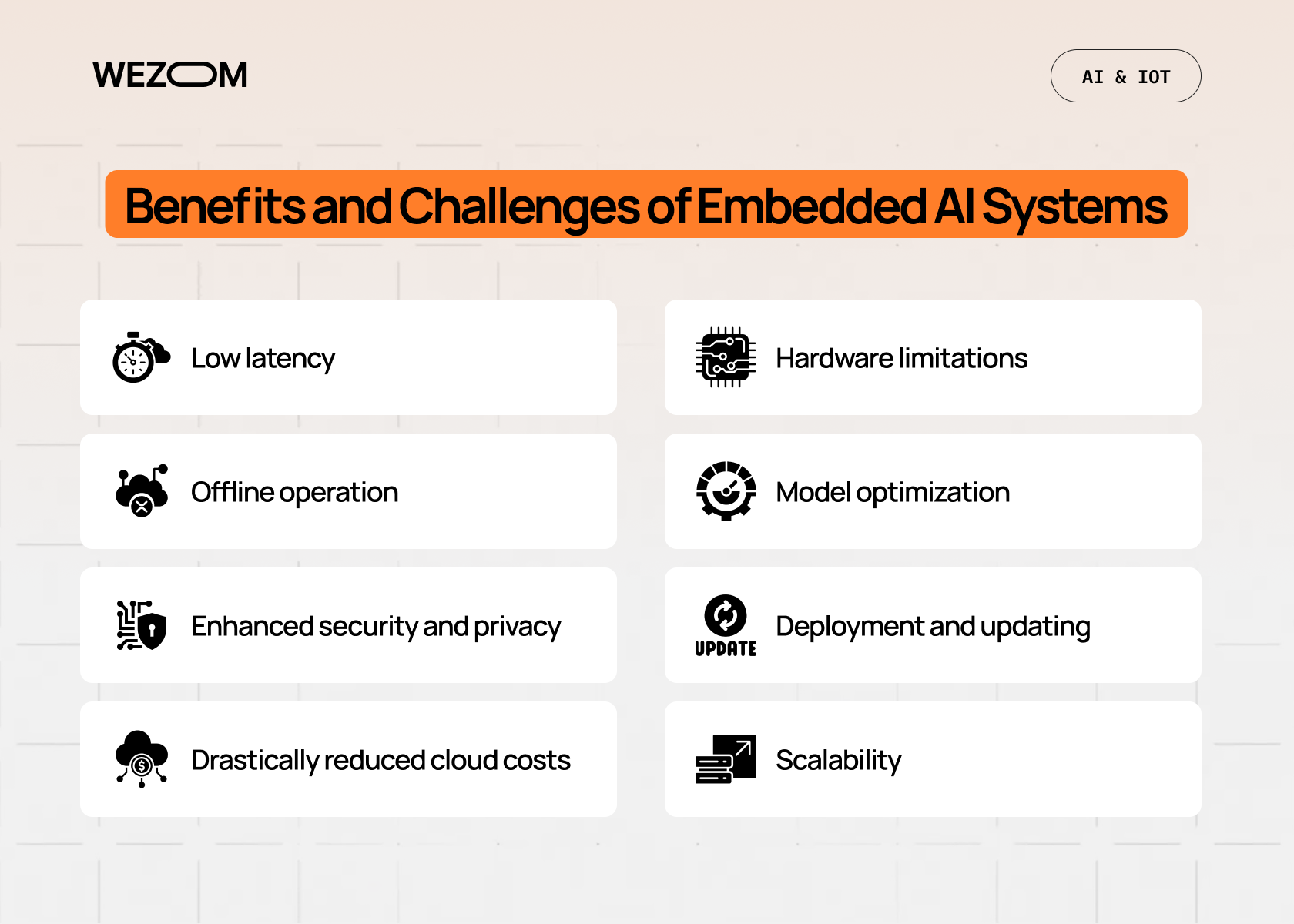

Benefits and Challenges of Embedded AI Systems

Like any other digital technology, embedded AI requires a balance between hardware capabilities and software requirements. Despite significant advantages such as:

- Low latency. Since data doesn't travel to and from the server, response times are reduced to milliseconds. This can be critical for emergency braking systems or industrial robots, where delays can lead to accidents.

- Offline operation. Your equipment remains highly intelligent in any location, whether in a deep mine, the open ocean, or any other area with poor 5G coverage.

- Enhanced security and privacy. Data is processed and optionally deleted directly on the device, which is a mandatory requirement for medical and security systems. This reduces the risk of interception of confidential information to zero.

- Drastically reduced cloud costs. You no longer need to pay for powerful GPU servers and massive amounts of outgoing traffic to support your embedded AI applications, as each device within your AI system handles the bulk of the computing work, consuming minimal energy.

…such systems face a number of implementation challenges, including:

- Hardware limitations. Unlike the infinitely scalable cloud, embedded AI is limited by a few megabytes of RAM and processor clock speed.

- Model optimization. Scaling a resource-intensive neural network down to a microcontroller requires specialized data science skills that not all development teams can boast.

- Deployment and updating. Updating a model on 10,000 sensors is more complex than rebooting a single server – it requires a reliable over-the-air update system to maintain the AI's relevance.

- Scalability. Developing for specific hardware often hinders the rapid porting of a solution to other processor types. Therefore, well-thought-out architecture planning from the start is required.

If you want to gain all the above benefits and overcome the challenges, you can delegate your embedded AI project to WEZOM. Contact us at your convenience, and we’ll discuss with you our potential tech partnership.

When Businesses Should Consider Embedded AI Solutions

We recommend considering embedded artificial intelligence if your business meets at least two of the following criteria:

- Low latency is critical for system operation. If your automation relies on drones, high-speed line control sensors, or medical life-support devices, i.e., hardware that must make instantaneous decisions, embedded AI will be the only way to achieve this without delays and data risks.

- Devices must operate reliably without constant connectivity. If your automation system components are located in hard-to-reach locations, or you sell equipment to users whose internet connection may be unstable, embedded AI can ensure that your smart solutions don't become useless when the Wi-Fi goes down.

- Data privacy or regulatory constraints limit cloud processing. If you work in highly regulated industries that need to ensure compliance with GDPR, HIPAA, banking secrecy, and more, embedded AI will help you ensure that customer data never leaves a specific device.

- Scaling AI across thousands of distributed devices is needed. If your business model involves installing sensors in every store, every device sold, and so on, the costs of cloud processing for millions of small transactions will be colossal. At the same time, transferring computing operations to edge devices will open a quick path to profitability.

As you can see, embedded edge AI is a logical step in the IoT evolution, as it saves business owners resources and provides instant service to customers without colossal cloud costs or the risk of data leaks. If you're considering implementing such solutions in your company, write or call us, and we'll implement your project from proof-of-concept to its scaling, optimization, and maintenance.

FAQ

Which industries use embedded AI the most?

Leading industries include those where delays or connection losses are extremely costly: automotive, manufacturing, and healthcare. Such solutions are also being actively implemented in the smart home and retail sectors, where devices must operate autonomously and ensure a high level of user data privacy.

How is embedded AI different from traditional embedded software?

While traditional embedded software relies on rigid if-else algorithms, embedded AI solutions are based on trained models that independently recognize complex patterns that cannot be described by conventional rules.

How secure are embedded AI systems?

Since with AI in embedded systems data is processed locally and not transmitted to the cloud, the risk of interception during transmission is effectively eliminated. However, new risks may arise, such as adversarial attacks or attempts to steal intellectual property directly from the chip. This is why it is important to invest sufficient effort in memory encryption and secure boot mechanisms at the hardware level.

How long does it take to implement embedded AI in an existing product?

The implementation timeline depends on data readiness and task complexity. On average, the cycle from idea to proof of concept takes three to six months. Data collection and labeling usually start within four weeks and can last for several months. Model training and optimization take a month or more, while deployment and testing require approximately four to six weeks.

Can existing embedded systems be upgraded with AI?

Yes. If the current microcontroller has sufficient memory and processing power, such as STM32 or ESP32 chips, a TinyML model can be deployed via a firmware update. If resources are insufficient, compact AI coprocessors or modules, such as NVIDIA Jetson devices or Hailo chips, can be integrated to handle all AI-related computations.