Would you like to know how digital tech can change the field of freight transportation? Actually, besides other advantages, digital tools can provide uncompromising transparency and control to the most complex segments of the automotive service. In one of our recent projects, we helped automate the business of a Ukrainian company, a leader in the heavy transport maintenance and tire leasing sector.

Who Was The Client?

We were approached by the enterprise company, a pioneer of tire leasing service in Ukraine. Since 1992, the company's team has been providing fleets with a full range of services in the selection, maintenance, repair, insurance, and leasing of tires for tractors, trailers, and trucks. Today, our client has 16 tire fitting stations throughout Ukraine.

It’s worth mentioning that truck tire maintenance is a complex and resource-intensive service that requires the involvement of narrow-focused specialists and expensive equipment. During the 30+ years of its existence, the company has developed and implemented dozens of innovations in this field, and one of them was the tire leasing service, first on the Ukrainian market.

It's almost the only company in Ukraine that today provides heavy transport tires for rent. This service is in great demand since the cost of even one new tire for a tractor is very high. Far from every entrepreneur or small company can afford to change truck tires, so renting "wheels" has become a reasonable solution. From our experience in the industry, almost everyone who has anything to do with logistics and freight transportation has either used their service or at least knew about it.

What Was The Client’s Request?

As not every fleet can afford to replace all the tires on a truck at once, and such expenses have to be planned in advance, businesses often take loans for them. At the same time, leasing services for transportation companies can be a cost-effective alternative: with it, roadworthy wheels could be received "here and now" at an affordable price. But how could the client make such a service profitable?

To begin with, the condition of the leased tires must be carefully monitored. When actively used, the tire loses its resource: its protector (a working track, a "pattern" of the wheel) wears off over time due to friction. Excessive wear of the protector means the loss of the tire because it becomes dangerous to use.

The cost of tire renting is calculated according to a special formula, which depends on the type of transport, the period of use, the mileage, and the technical condition of the wheel (the level of wear of the material, the remaining depth of the protector, the angles of inclination of the wear, the presence of damage, cuts, etc.). For this, the company's specialists inspect rented tires at their service stations, taking into account the necessary parameters and performing maintenance.

Until recently, this entire process was documented on paper. It was very slow and accompanied with mistakes and human factor risks. The specialist had to inspect the tires using a detailed form in which all the necessary parameters had to be manually fixed. Such forms must be filled out for each truck and tire (there may be a dozen of them on only one vehicle). After that, this document had to be scanned and sent to the central office, where the data was manually transferred to the accounting system and used in calculations to issue an invoice for payment.

That’s why the client's team turned to us to automate and simplify this complex and resource-intensive process. It was also necessary to make the data collection procedure transparent and bring all the parameters to a single standard. This was needed to eliminate corruption risks, streamline tasks in the accounting department, and correctly assess the real volume of this market in Ukraine.

Goals and Objectives of The Project

The client gave us a detailed list of technical specifications and provided a clear understanding of the desired results. Specifically, to solve the problem of tire inspection, it was necessary to automate the inspection process through a mobile application. In this truck tire program, the company’s employees could record all data on the tire's condition and provide the client with recommendations for its operation (maintenance, repair, replacement, etc.). The platform was supposed to work on Android tablets, specially purchased for these needs.

Thus, the project's main goal was to implement a mobile application with functionality for tire inspection and maintenance according to the company's unique business model. To achieve it, we had to solve several tasks:

- Create a native mobile application for Android;

- Implement all necessary service functionality: license plate recognition, moderation logic of tire inspection, generation of wheel formulas, etc.

- Develop a backend to process the data collected using the application.

What Technologies Did We Use?

Our team came up with a tech stack based on the needed functionality and system requirements. The license plate decoder app had to work on 10-inch tablets and be fast and easy to maintain. That's why we settled on native mobile development on Kotlin.

To create an admin panel (i.e., backend), our developers considered using one of the popular CMSs. However, during the discussion with the client, our team decided to choose GraphQL for better product’s flexibility. Also, we supplemented the core technology with PHP, React, and MySQL.

What Approach to Work Did We Use?

The first stage of this project was the Discovery Stage. During this, we worked out the client's technical specifications, analyzed the project requirements, and formed a backlog. Also, at this stage, we had to engage our UX designer to create prototypes for alignment with the client.

When the concept, design, and tech stack were agreed upon, we proceeded to the technical part of the project – frontend and backend development. Our developers work according to the Agile Scrum methodology, in which tasks must be divided into small sprints and performed by small autonomous teams. Thus, at this stage, many processes were carried out synchronously, which made it possible to implement a complex app from scratch in less than six months.

How Did We Communicate with The Client?

The main communication channel between the client and us was the Telegram messenger, where we could answer the client’s questions and vice versa, as well as receive important feedback during our work process.

As for video meetings and calls, they took place on Zoom and Google Meet. Thanks to this, our work was greatly simplified by the technical savvy of the client's team, as they understood the nuances of software creation processes like no one else.

For each project’s sprint, we agreed on a scope of work and approximate time frames. At the end of each sprint, we reported to the client the actual hours spent and tasks completed. Specifically, our team demonstrated prototypes, elements, and modules (as well as their functionality in practice, if possible).

What Was The Challenge During The Development Process?

In this project, we paid special attention to UX, including the usability and ergonomics of the application. Indeed, tire inspection cannot always be performed under comfortable conditions – specialists can perform it outdoors, in gloves, in rain or snow, at night, etc.

That’s why we abandoned vertical screen orientation. After implementing the first wheel formula, it became clear that it was inconvenient to work with it as the elements were small to read and click. This forced us to focus on creating the UI in a horizontal orientation.

In addition, our team had to perform a great job on implementation of the feature aimed at indicating vehicle numbers correctly. The idea was to point a tablet’s camera at a car's license plate on-site and pull up all the necessary data automatically instead of entering numbers manually.

Our managers walked around truck parking lots and tried to scan different types of license plates. In particular, this license plate detection application had to take into account the following formats of license plates: Ukrainian standard plates (current format since 2004) and European plates of two formats. These capabilities required fine-tuning. Because of this, we got "stuck" a little.

However, custom development of the recognition component could be accompanied by significant errors, while the use of third-party services was not suitable for the client since the client wanted to obtain full intellectual property rights to the product. As a result, the client insisted on custom development, and we made every effort so that the application could recognize license plates in different lighting conditions, at different angles, different image clarity, etc. Specifically, we provided it with everything necessary so that users did not have to spend a lot of time getting it in the right position to correctly capture the image. Despite this challenge, we still managed to complete this license plate reader app by the deadline.

Our colleagues at HiddenBrains are also engaged in similar projects like us. Their successful case study on digitalization in the oil and gas industry not only confirms the importance of innovation in this sector but also emphasizes the significance of digital transformation across various industries. This example serves as excellent evidence of how digitization promotes the development of smarter and safer work methods in the industry, while also highlighting the need to extend such initiatives to other sectors.

What We Ended Up Developing

The result of our work was a mobile application that has no analogs in its niche. It automated the tasks within the technical tire inspection according to the client's business model. Also, it correctly moderated all possible scenarios of truck inspection at the tire assembly station – both when adding new vehicles to the database and when working with existing customers.

Now, let's check the main screens and modules of the solution.

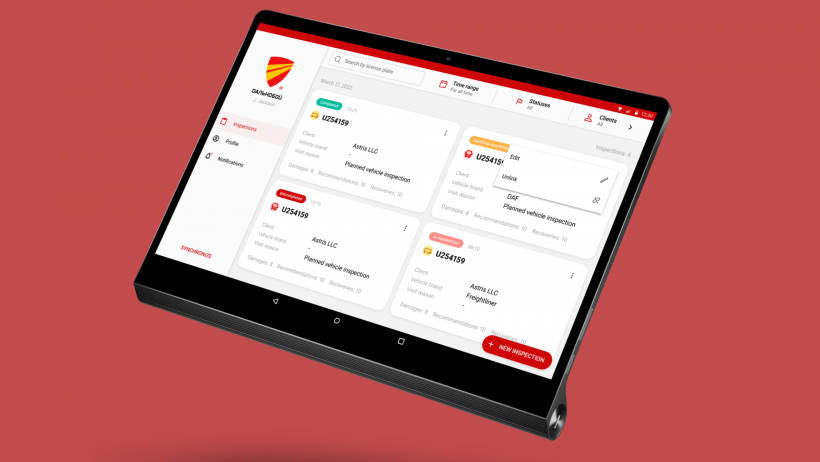

Navigation and search tools, as well as service request cards, are displayed on the main screen. Each card contains the name of the client's organization, the number and brand of the vehicle, the reason for the request, the maintenance service history, etc.

To add the new service request, it is enough to point the camera of the tablet at the license plate – it will be recognized automatically. If the number is in the database, all necessary data will be pulled from it automatically. If there are no numbers in the database, the new vehicle can be added to it immediately.

The type, class, and model of the vehicle are shown on the screen – it can be a truck, a tractor, or a trailer. For different types of transport, the formulas for calculating the cost of renting tires will be different. Accounting data is also located here: it can be the customer’s company, drivers' contacts, scans of the technical passport, photos of license plates and cars, odometer readings, etc.

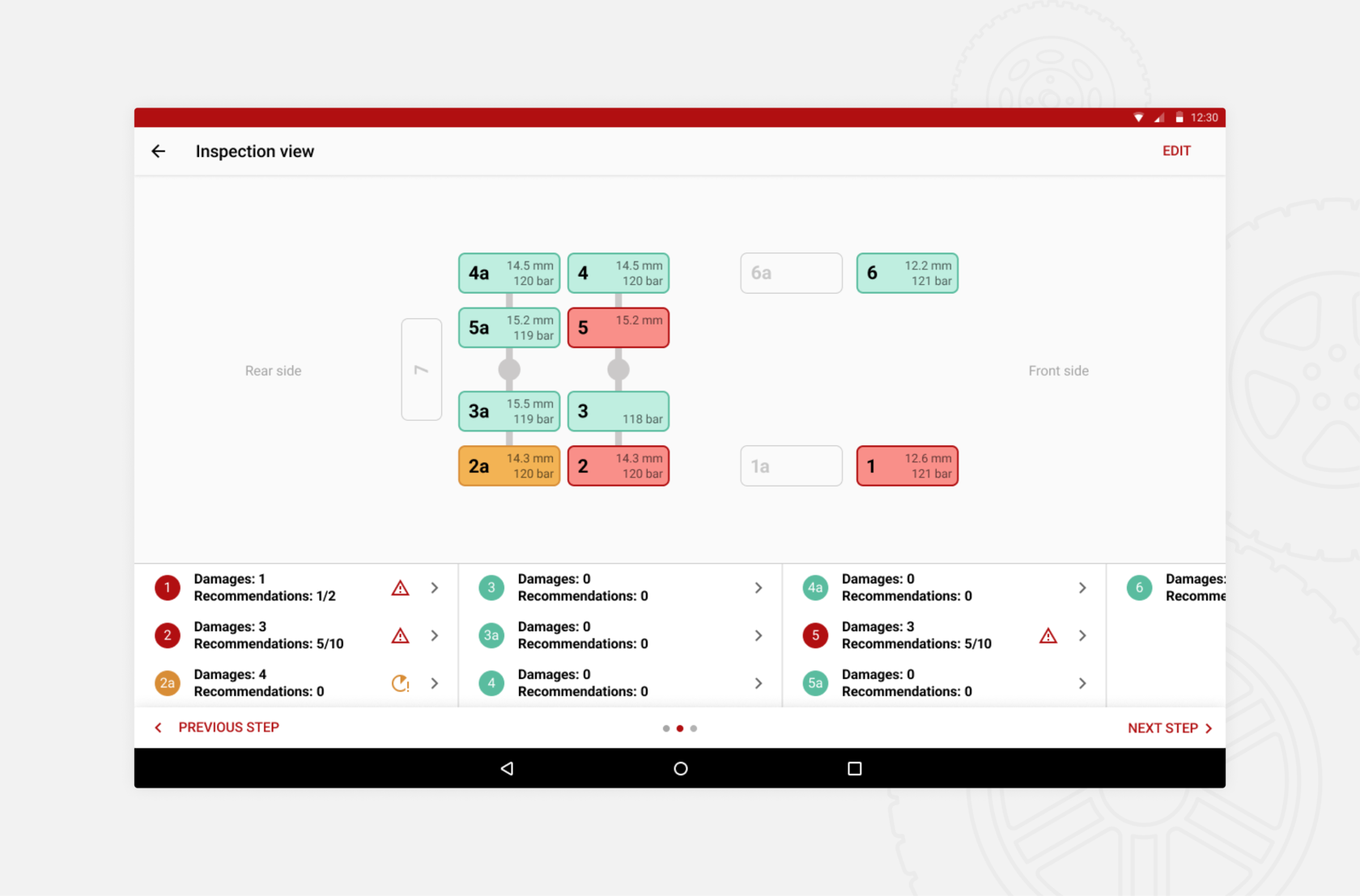

A screen with a wheel formula was implemented specifically for inspection. On it, we see an infographics that schematically represents the view of the vehicle from below. Each "wheel" is a separate tire compartment with its own number. At the same time, whole tires are highlighted during the inspection process in green, and their problems are in red.

Each wheel has its own screen, which shows all the necessary information about the tire. This is a brand, appearance, model, size, serial number, etc. Here, the inspector can enter all the technical parameters of the wheel.

One of the most important indicators for tire inspection is the residual protector depth (RPD), which is measured in millimeters – it defines the level of abrasion of the tire protector. The tire usage bill largely depends on this indicator.

Finally, the inspector can capture tire wear and damage information through the tire patch screen. This screen can also provide specialists with recommendations on necessary services and further wheel usage.

From a technical point of view, the license plate reader software has several important features that made this alternative to manual procedure more effective:

- automated car plate recognition;

- complex moderation of inspection according to various triggers and scenarios;

- generation of wheel formulas implemented directly in the mobile application.

All the data collected through the UI goes to the backend. Here, the app performs service cost calculations for each wheel and for each vehicle. Now, it’s hard to imagine that until recently, this complex multi-step process was carried out manually.

Project Results

The tire management app we created allowed the client to automate tire inspection and diagnostics procedures. Client abandoned the paperwork that consumed a lot of time and money, affecting confusion and errors. The registration of inspections became simpler and speeded up significantly.

At the same time, the company managed to reduce the possibility of fraudulent inspection and corruption risks. After all, during the transfer of processes to the digital plane, employees’ neglect of any problems with tires disappeared. This was important from the point of view of road safety.

Also, with this app deployment, the quality of data collection has improved significantly, and the data itself has been standardized. This allowed the client to receive up-to-date information about assets and the state of the market as a whole. Thus, such digitization has opened up new opportunities for more complex business analytics, increasing the quality of decision-making.

Today, this license plate software has already been successfully launched. The WEZOM team is constantly working on app updates, refining the customer experience and adding new functionality. One of the nearest plans of updates is to implement interactivity in wheel formula schemes to make them clickable. This functionality was planned at the start of the project but was left for later. After all, the priority was the implementation of the key business logic.

For the WEZOM team, working on a commercial truck tire program has become one of the most unusual projects in the logistics sector in recent years. Now, we are sure that it is possible to automate almost any service – you only need to find the right idea and choose an experienced team capable of breathing life into it.