Think of HMI software like the dashboard in your car. You don't need to understand how the engine works, you just need to see your speed, fuel level, and warning lights. Simple, right?

Now scale that up to industrial machinery. Massive systems, thousands of data points, critical operations that can't afford mistakes. That's what HMI software handles every day in factories, power plants, and automated facilities worldwide.

Let's explore what's behind that interface and why getting it right makes all the difference.

What is HMI Software: meaning and definition

HMI stands for Human-Machine Interface. It’s like a translator between humans and machines. It's that visual dashboard (usually with buttons, graphs, and real-time data) that lets people monitor and control industrial systems without needing to understand complex machine code.

Machines speak a completely different language. They process data in binary, run on complex protocols and operate at speeds humans can't match. HMI software bridges this gap by converting all that technical chaos into something we can actually understand and interact with.

How does HMI software work?

Look, the working principle isn't rocket science, but it is elegant.

HMI software sits between the operator and the hardware (like PLCs, sensors, and actuators). When you press a button on the screen, the software translates that action into a command the machine understands. When the machine generates data, the HMI converts it into visual displays, charts, or alerts that make sense to humans.

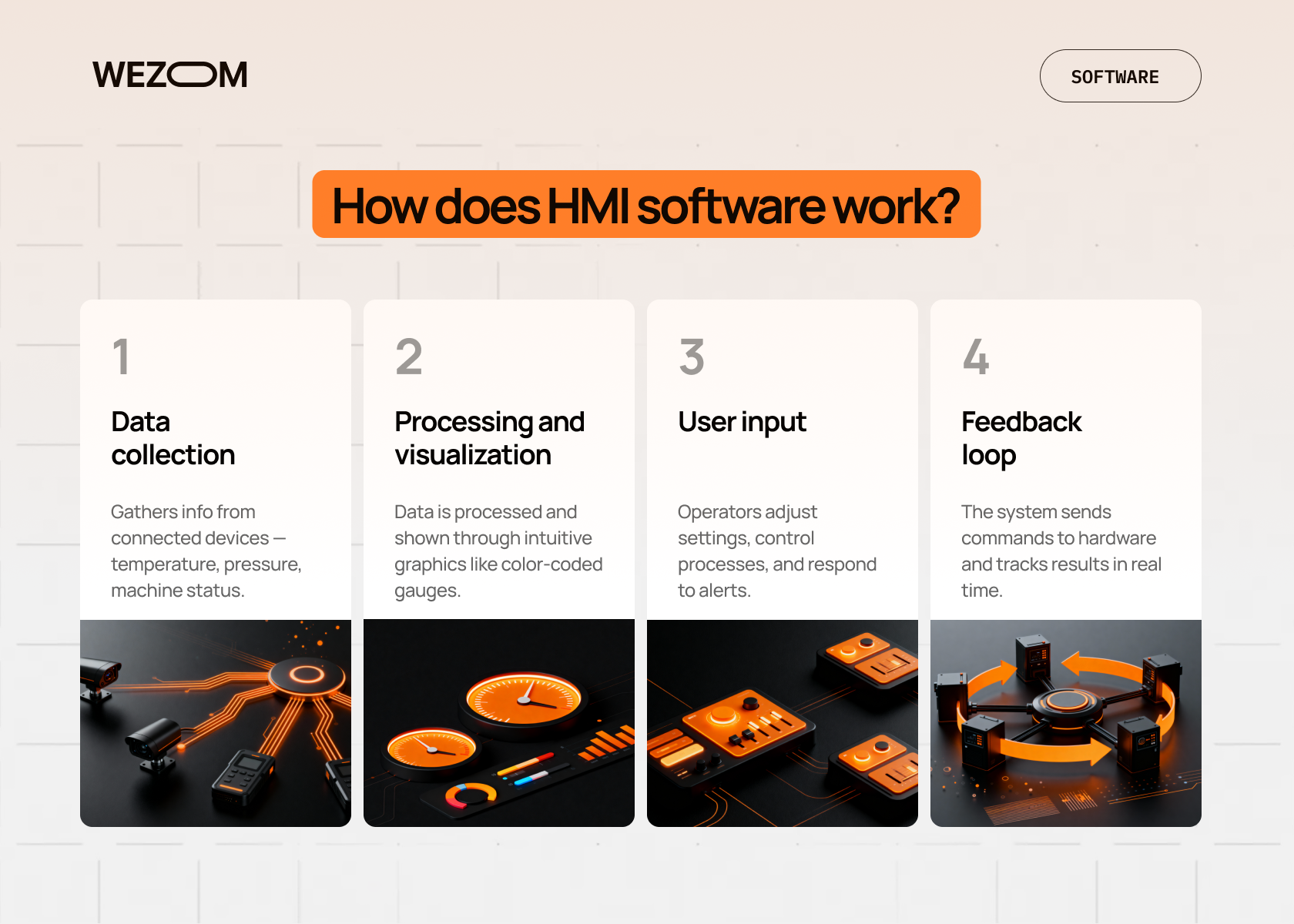

Here's what happens behind the scenes:

- Data collection. The software constantly pulls information from connected devices – temperature readings, pressure levels, machine status, you name it.

- Processing and visualization. Raw data gets processed and displayed through intuitive graphics. Instead of seeing "Temperature: 523.7K," you see a color-coded gauge that tells you at a glance whether everything's normal.

- User input. Operators interact with the interface to adjust settings, start or stop processes, or respond to alarms.

- Feedback loop. The system sends commands back to the hardware and monitors the results in real-time.

Applications of HMI Software

HMI software isn't limited to one industry. It's everywhere machines and humans need to work together.

Manufacturing

This is where HMI really shines. Production lines, assembly robots, quality control systems – they all need human oversight. Operators use HMI screens to monitor production rates, adjust machine settings, and respond to issues before they become costly problems.

Energy sector

Power plants (whether they're running on coal, nuclear, or renewables) rely heavily on HMI systems. The stakes are high here, you're managing systems that can't afford to fail. HMI software provides real-time monitoring of grid performance, equipment health, and safety parameters.

Automotive

Modern cars are basically computers on wheels, right? HMI software manages everything from infotainment systems to advanced driver assistance features. And in automotive manufacturing, HMI controls robotic assembly lines and quality testing equipment.

Healthcare

Medical devices need precise control and clear displays. HMI software in healthcare manages everything from diagnostic equipment to surgical robots. The interface has to be intuitive because doctors and nurses don't have time to figure out complicated controls during critical moments.

Plus, there's food and beverage processing, water treatment facilities, pharmaceutical production, packaging operations etc.

HMI Software Development Process

So what is HMI development exactly? Developing HMI software is a multi-stage process that requires planning, design expertise, and constant testing.

Through planning and design you define what the system needs to do. What data needs to be displayed? What controls do operators need? What safety features are essential?

You also need to consider the hardware you're working with. Different PLCs and control systems use various protocols. Your HMI needs to speak their language.

WIth UX/UI Design things get interesting. A poorly designed HMI can be worse than no HMI at all.

Good HMI design follows some basic principles:

- Clear visual hierarchy

- Intuitive navigation

- Color-coding that makes sense

- Responsive layout for different screen sizes

- Accessibility features

You want operators to know exactly what they're looking at within seconds. No guessing, no confusion.

Now developers build the actual software. They integrate communication protocols, create the visual elements, implement logic for data processing, and set up alarm systems.

But here's the critical part – testing. You can't just deploy HMI software and hope it works. You need simulation testing, user acceptance testing, safety validation, and performance optimization.

Let’s not forget about hardware integration. The software needs to connect with physical devices. This means configuring communication drivers, mapping data points, and ensuring reliable data exchange. It's not always smooth sailing (network latency, protocol mismatches, and hardware compatibility issues can be a headache).

And finally, support and updates. You need ongoing support, security patches, feature updates, and performance monitoring. Industrial systems evolve, and your HMI needs to evolve with them.

Benefits of HMI Software Solutions

Why bother with HMI software at all? Can't operators just manage without it?

Technically, yes. But you'd be throwing away massive advantages.

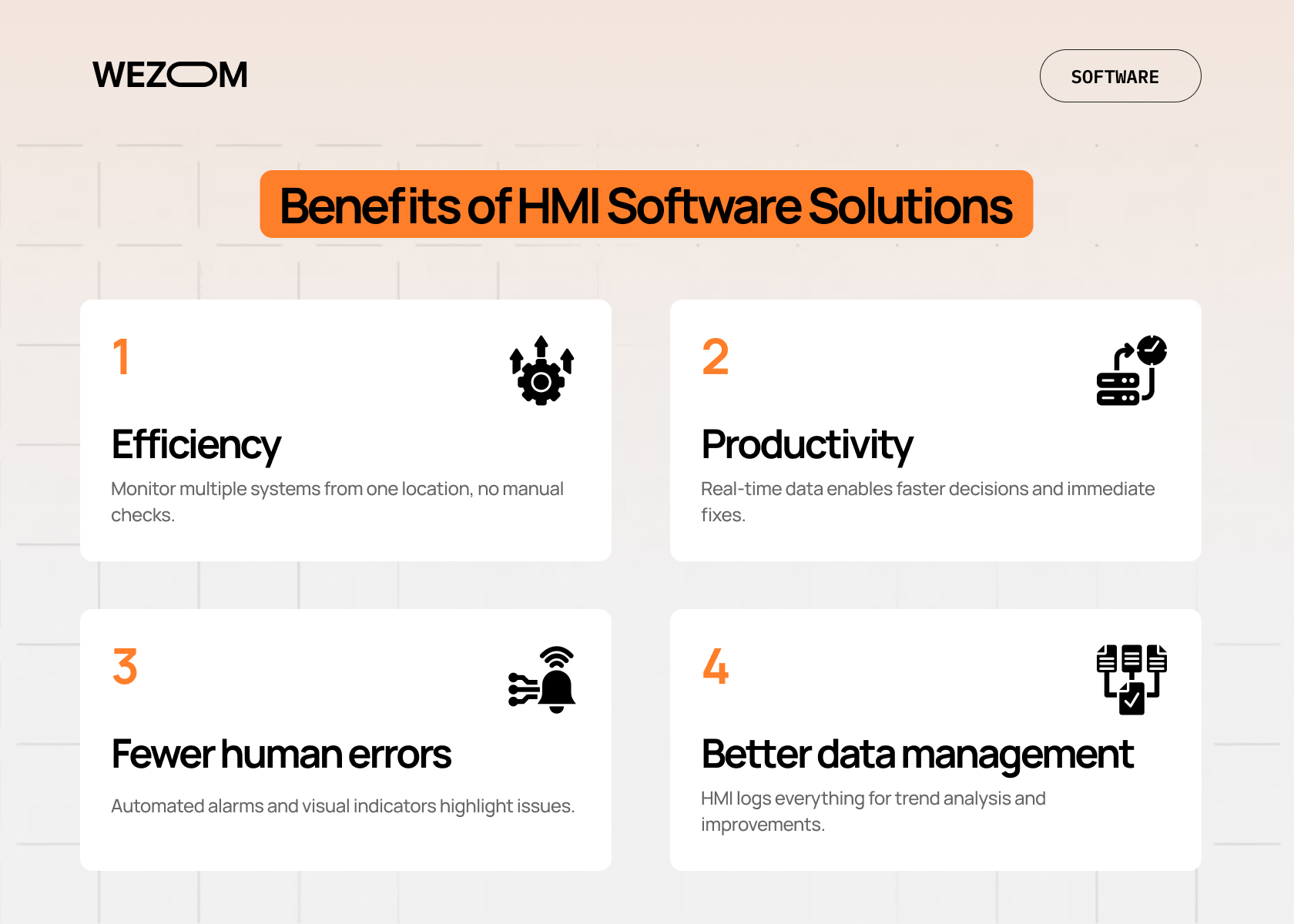

Efficiency. Operators can monitor multiple systems from a single location. No more walking around the factory floor checking gauges manually.

Productivity. Real-time data means faster decision-making. When you spot a problem immediately, you can fix it immediately.

Fewer human errors. Automated alarms and visual indicators reduce the chances of missing critical issues. The system literally tells you when something's wrong.

Better data management. HMI software logs everything. You can analyze trends, identify inefficiencies, and make data-driven improvements.

Here's how these benefits translate into real operational improvements:

| Benefit | Impact | Example |

|---|---|---|

| Real-time monitoring | Instant visibility into operations | Detect equipment anomalies before failure |

| Centralized control | Reduced operator workload | Manage 10 machines from one panel |

| Data logging | Improved decision-making | Analyze production trends over months |

| Safety improvements | Fewer workplace accidents | Automated shutdown on dangerous conditions |

| Cost reduction | Lower maintenance costs | Predictive maintenance prevents breakdowns |

This means that HMI software pays for itself. The cost reduction from predictive maintenance alone can cover your investment. Everything else (the safety improvements, the productivity gains, the better decision-making) is all a bonus.

The future of HMI software development

So where's this all heading?

AI and machine learning are already making HMIs smarter. By 2025, over 35% of HMI systems are predicted to use artificial intelligence to improve machine control, predictive maintenance, and user adaptability. Your HMI won't just display data, it'll predict problems before they happen and suggest optimal settings.

Cloud-based HMI is gaining traction too. Instead of being tied to on-premises hardware, you can access your HMI dashboard from anywhere. Remote monitoring is becoming more essential.

IoT integration means HMI systems can connect with more devices than ever before. We're talking about truly interconnected factories where every sensor, every machine, every process is visible through a single interface.

AR and VR interfaces are starting to emerge in industrial settings. Imagine wearing AR glasses that overlay HMI data directly onto the equipment you're looking at. It sounds like science fiction, but it's already happening in some facilities.

The truth is, HMI software is becoming less about displaying data and more about intelligent system management. We're moving toward interfaces that not only show you what's happening but actively help you make better decisions.

But here's what won't change: the fundamental need for clear, intuitive design. No matter how advanced the technology gets, if an operator can't understand the interface quickly, it's failed its purpose.

FAQ

What are common examples of HMI software?

You'll find HMI software from major manufacturers like Siemens WinCC, Rockwell Automation FactoryTalk View, and Schneider Electric Vijeo Designer. There's also Wonderware InTouch, Ignition by Inductive Automation, and AVEVA InTouch HMI. Each has its strengths depending on your industry and hardware setup.

Which industries use HMI systems the most?

Manufacturing dominates HMI usage, but you'll find it heavily used in automotive (both production and in-vehicle systems), energy and utilities, oil and gas, food and beverage processing, pharmaceuticals, and water treatment. Basically, anywhere there's industrial automation and process control.

How does HMI improve industrial automation?

It provides real-time visibility into operations, reduces response time to problems, centralizes control of multiple systems, and minimizes human error through automated alerts and visual indicators. The result? Better productivity, lower costs, and safer operations.

How to choose the right HMI software for your business?

Start with your hardware, make sure the HMI software supports your existing PLCs and control systems. Consider scalability (can it grow with your operation?), ease of use for your operators, vendor support and documentation, and total cost of ownership including licensing and maintenance. Don't just pick the cheapest option. Pick the one that actually fits your needs.

How much does HMI software development typically cost?

It varies wildly. Simple HMI projects might start around $10,000-$15,000. Complex systems with custom features, extensive integration, and specialized requirements can run into six figures. Factors include the complexity of your operation, hardware integration needs, customization requirements, and ongoing support. It's worth investing in proper development upfront rather than dealing with a poorly designed system later.