Models selected for cost-effective accuracy

Instead of resource-intensive models, we opted for a dual-model approach. Specifically, we chose the lightweight YOLOv8n model (for real-time object detection) and the high-precision RT-DETR v2 model (for deep server-side analysis), allowing us to achieve enterprise-level accuracy without incurring high operational costs. Thanks to this, the system captures every object in real time, providing 100% verified data for inventory reports.

Custom hardware architecture for freedom from vendor lock-in

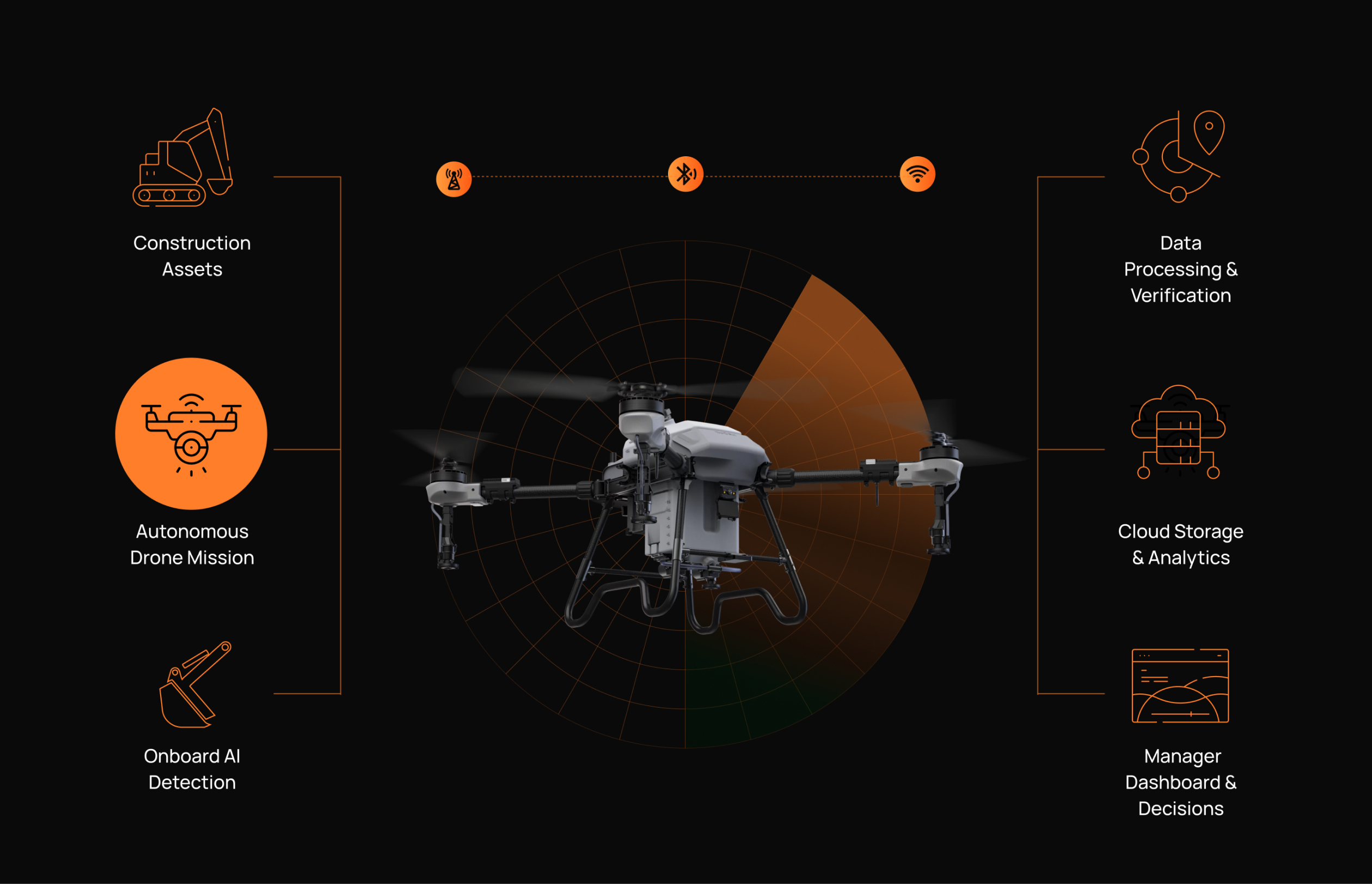

To eliminate the high costs and limitations of commercial drone ecosystems, we developed a custom 450-500mm quad multirotor UAV platform. Using a Radxa Zero 3W companion computer and an open-architecture ArduPilot-compatible Flight Controller, we ensured complete technical independence. This frees the client from subscription fees or hardware limitations of a single vendor, enabling deep customization and seamless integration with corporate IT systems.

Simplified decision-making logic

WEZOM implemented an automated pipeline that performs edge processing directly on the drone. The system instantly filters out irrelevant data, synchronizing only the necessary information with the base station. This reduces the time between the flight and the final report, enabling site managers to make quick, data-driven decisions on equipment allocation and facility safety.

Proven reliability

On construction sites, the absence of even one unit of expensive equipment can lead to significant project delays. Therefore, we optimized the AI model to ensure that even small or partially hidden objects are never overlooked, training it on thousands of diverse construction site images. This minimized the risk of asset loss and unplanned replacement costs, even in the most challenging conditions.

Python

- Python – it served as the main language for developing the detection logic and integrating YOLOv8 and RT-DETR models.

YOLOv8

- YOLOv8 – this model is good for onboard real-time inference due to its high speed and low resource consumption on edge devices.

OpenCV

- OpenCV – it was used for processing drone video footage, frame transformation, and visualizing bounding boxes.

ArduPilot and MAVLink

- ArduPilot and MAVLink – it was used for flight control and communication between the drone's payload and the flight controller.

Radxa Zero 3W

- Radxa Zero 3W – we used Radxa Zero 3W for real-time edge inference on the drone and a GPU-enabled server for high-accuracy batch processing.

We make the construction site monitoring process fully autonomous. By using UAVs for monitoring tasks, our team eliminated the need for manual site checks that previously took hours. Instead, this custom solution by WEZOM provides real-time visibility of the assets’ location and condition, thereby reducing the risk of its loss and ensuring project managers always have a single source of truth at hand.

Operational efficiency and risk reduction

The system’s deployment reduced inspection time, enabling more frequent site checks without increasing overhead expenses. Also, it minimized human presence in hazardous construction zones, which made it easier for the client's company to ensure their operations comply with safety standards. Another significant result was the system's top accuracy in various construction site conditions, as well as its absolute independence from third-party vendors.