[author_forms:67]Your delivery truck just changed routes. Again.

Not because the driver decided to — the AI did. It detected a 12-minute traffic delay three miles ahead, recalculated fuel costs across seven alternative paths, checked warehouse dock availability, and rerouted the entire fleet. All in 1.3 seconds. This is logistics in 2026.

In this article, we'll break down how AI and automation are reshaping logistics software development, what technologies are driving the change, and what it takes to implement them without breaking your budget or your systems.

Why Logistics Software Modernization Is Critical in 2026

Supply chains are under more pressure than ever. Global disruptions happen quarterly now. eCommerce orders are exploding, costs are climbing, and sustainability isn't optional.

The old systems can't handle it.

A warehouse management software (WMS) built ten years ago wasn't designed for IoT sensors or autonomous vehicles. Supply chain optimization now demands systems that adapt on the fly.

Cost pressures are brutal. The U.S. trucking industry is short by over 80,000 drivers in 2025. Companies using artificial intelligence in logistics are seeing 5-20% cuts in operational costs, according to McKinsey.

Modern logistics require end-to-end transparency. Real-time tracking and telematics are essential.

By 2025, up to 25% of warehouse tasks could be automated. And emissions tracking with route optimization for fuel efficiency? Regulatory requirements now.

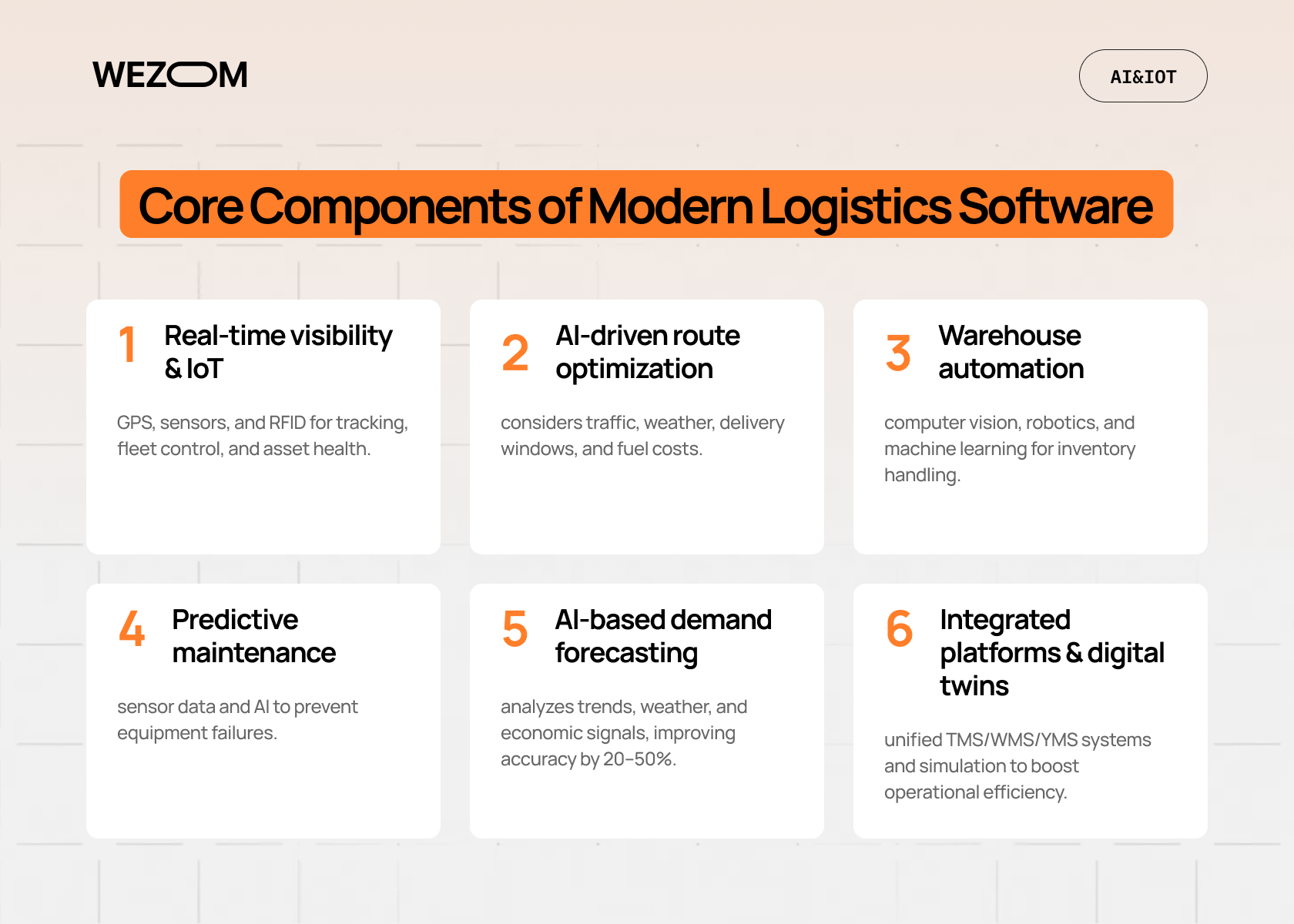

Core Components of Modern Logistics Software

Real-time tracking and telematics form the nervous system. IoT in logistics enables GPS devices, IoT sensors, and RFID tags to constantly feed data back. Fleet management software monitors driver behavior, fuel consumption, and maintenance needs.

Route optimization engines are the brains — AI-driven systems considering traffic, weather, delivery windows, and fuel costs simultaneously.

Automated inventory systems keep warehouses humming. Computer vision identifies products. Robotics moves them. Machine learning predicts demand and triggers reorders automatically.

Predictive maintenance dashboards are essential. Sensors generate data about performance, temperature, vibration. AI flags issues before equipment fails.

AI-based demand forecasting analyzes social media trends, weather, economic indicators to predict customer demand. Forecast accuracy improves by 20-50%.

Integrated modules — TMS software, WMS software, Yard Management Systems — are now unified platforms coordinating operations across the logistics ecosystem.

Digital twins simulate changes before implementing them. Companies see up to 20% improvements in space utilization.

How AI Is Changing Logistics Software Development in 2026?

Predictive analytics for demand and stock ingests data from everywhere — point-of-sale systems, supplier databases, social media, macroeconomic trends, weather patterns. Machine learning finds patterns humans would never spot.

Computer vision for warehouse automation is transforming physical operations. Cameras identify products, inspect for damage, and guide automated systems. DHL's autonomous mobile robots (AMRs) with computer vision increased efficiency by 30%.

AI-powered dynamic routing recalculates constantly based on real-time traffic, new orders, vehicle breakdowns, or weather. They're achieving 30% better transit times and fuel consumption.

Intelligent task allocation means software decides who does what, when. It considers skill levels, locations, and dozens of factors to assign tasks optimally.

AI-enhanced cargo inspection catches problems before shipments leave, dramatically reducing returns.

NLP-enabled customer communication means chatbots that handle 80-90% of routine inquiries without human intervention.

And there's AI decision support for managers — recommendations instead of drowning in reports.

AI-Driven Automation in Fleet and Warehouse Management

Fleet management used to be about tracking trucks and hoping they didn't break down. Now it's predictive and frighteningly smart.

AI monitors every vehicle constantly — engine performance, tire pressure, brake wear, fuel efficiency, driver behavior. Predictive analytics reduces downtime by 50%, cuts breakdowns by 70%, and lowers maintenance costs by 25%.

Dynamic route optimization happens in real-time. The system knows traffic patterns, considers driver hours-of-service regulations, and factors in fuel costs. It finds efficiencies human dispatchers can't match.

Warehouse Automation with AI

Robotics handle physical work. AGVs and AMRs transport goods. Robotic arms pick, pack, and palletize.

But the real key is orchestration. AI manages the entire operation, deciding which robot handles which task and optimizing pathways to avoid congestion.

AI warehouse automation means the system always knows what you have and when you'll need more. Computer vision conducts continuous inventory counts. Companies report 35% reductions in inventory levels while achieving 65% better service levels.

How Automation Synchronizes Fleet and Warehouse Operations

When a truck is 30 minutes away, the system automatically adjusts dock scheduling, prepares unloading equipment, and queues up outbound orders. Everything flows seamlessly.

AI logistics solutions coordinate loading schedules, plan warehouse layouts, and synchronize delivery windows with inventory availability.

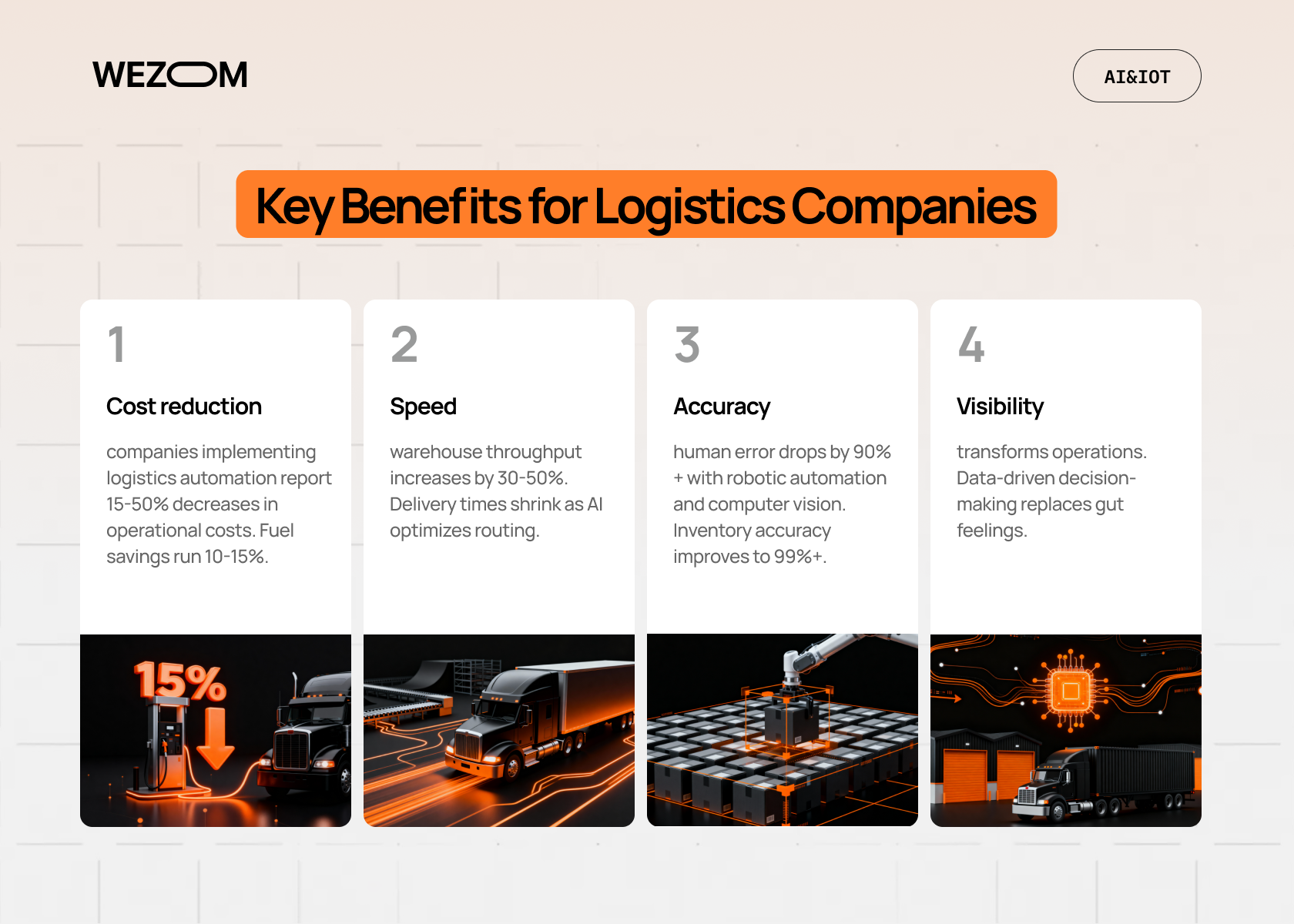

Key Benefits for Logistics Companies

Cost reduction: companies implementing logistics automation report 15-50% decreases in operational costs. Fuel savings run 10-15%.

Speed: warehouse throughput increases by 30-50%. Delivery times shrink as AI optimizes routing.

Accuracy: human error drops by 90%+ with robotic automation and computer vision. Inventory accuracy improves to 99%+.

Visibility transforms operations. Data-driven decision-making replaces gut feelings.

Cybersecurity and Compliance Requirements in 2026

Here's the uncomfortable truth: all this connectivity creates massive security risks.

The logistics sector accounts for 7.5% of all cyber incidents in the EU. In 2025, the transport sector saw 97 cyberattacks per hour globally. Ransomware attacks account for 38% of attacks on the transport industry.

Secure telematics means encrypting all vehicle data transmission. IoT device security is critical because thousands of sensors generate data constantly.

Regulations are tightening. GDPR, CCPA, DOT, FMCSA — non-compliance carries heavy fines. Your logistics software development needs built-in compliance features.

Zero trust architecture means to verify everything. When 58% of logistics managers cite cybersecurity as a major concern, and the cybersecurity in logistics market is growing at 12.1% annually to reach $37.26 billion by 2037, security is essential.

How AI and Automation Reduce Operational Expenses

AI-optimized routing cuts fuel consumption by 10-15%. Empty miles drop by 45% when AI matches available capacity with shipping needs.

Warehouse automation changes what workers do. One automated warehouse processes the same volume as a traditional facility with 40-50% fewer staff. But labor shortages are real — Deloitte projects 3.8 million manufacturing and logistics jobs will be needed by 2033, with nearly half potentially unfilled.

AI-powered inspection systems catch damage before products ship. Returns drop. Customer satisfaction improves.

Automated picking with computer vision reduces errors by 90%+.

Predictive maintenance catches problems before shutdowns. BMW's AI-supported maintenance saves over 500 minutes of disruption per plant annually.

Challenges and Risks of Building Logistics Software in 2026

Your new AI-powered WMS software needs to talk to existing ERP, TMS, customer systems, carrier systems — the list goes on. Each integration has its own API quirks.

Many companies run operations on systems built 10-20 years ago. They can't handle modern AI workloads. Companies face massive rip-and-replace projects or continuing with obsolete technology.

Warehouse robots break down. The maintenance requirements for robotic fleets are real.

AI and automation require serious capital. A full warehouse automation system can run $10-50 million. ROI takes 2-4 years.

There aren't enough people who understand both logistics and advanced AI/ML. 55% of logistics firms report talent shortages as a major barrier.

How to Choose the Right Technology Stack and Vendor

SaaS solutions make sense when operations are standard and you need to launch quickly. Oracle, SAP, Blue Yonder offer comprehensive platforms.

Custom development makes sense for unique workflows and complex integration requirements.

For AI/ML workloads, consider AWS, Azure, or Google Cloud with their AI platforms and IoT services.

You'll need AI/ML specialists, IoT engineers, cloud architects, DevOps engineers, and logistics domain experts.

When evaluating vendors, security should be top priority. Ask about encryption, compliance certifications, penetration testing, and incident response procedures. Cyberattacks through supply chains have increased tremendously.

Real-World Impact: What Companies Are Seeing

The numbers speak for themselves. Here's what industry leaders are achieving with AI and automation.

| Company/System | Technology Applied | Measurable Result |

|---|---|---|

| UPS ORION | AI route optimization | $400M+ annual savings |

| DHL warehouses | Autonomous mobile robots | 30% efficiency increase |

| Amazon fulfillment | Warehouse robotics + AI | Millions in labor cost savings |

| FedEx | AI predictive analytics | Optimized fleet utilization |

| Walmart + Symbotic | End-to-end automation | Real-time inventory intelligence |

The pattern is clear: AI adoption isn't just improving operations incrementally — it's creating entirely new performance benchmarks.

Conclusion

The logistics industry is at an inflection point.

Companies investing in AI in logistics now are building competitive advantages that will compound for years. The benefits of AI in logistics are measurable and real.

But implementation requires investment, expertise, and patience.

Ready to explore how AI is used in logistics for your operations? Our team specializes in building custom logistics technology trends solutions that deliver real ROI. Let's discuss how we can transform your fleet and warehouse management.

Contact us today to get started.

FAQ

How does AI improve fleet management?

AI monitors vehicle performance, predicts maintenance needs before breakdowns, optimizes routes in real time, reduces fuel consumption, and improves safety. Companies report up to 50% reductions in downtime and 10–15% fuel savings.

What are the benefits of predictive analytics in logistics?

Predictive analytics in logistics improves demand forecasting accuracy by 20–50%, optimizes inventory levels, predicts equipment failures, and enables proactive, data-driven decision-making.

How does AI help reduce fleet maintenance costs?

AI analyzes sensor data from vehicles to detect anomalies and flag potential issues before they cause breakdowns. This enables scheduled maintenance instead of emergency repairs, resulting in up to 25% cost reductions and 70% fewer breakdowns.

What technologies enable real-time fleet tracking?

Real-time fleet tracking is enabled by GPS systems, cellular communication, IoT sensors, edge computing, cloud platforms, and mobile applications that together provide second-by-second visibility into fleet operations.

What are the cybersecurity risks in AI-powered logistics?

Key cybersecurity risks include ransomware attacks (38% of transport industry incidents), DDoS attacks (24%), third-party breaches, IoT device vulnerabilities, and data theft. Globally, the logistics sector faces an average of 97 cyberattacks per hour.