Warehouse management is undergoing a true revolution.

Customers now expect delivery within hours, not days. Labor costs are rising. Competitors are becoming faster and more precise. Inventory errors are no longer affordable. And automation is no longer just a competitive edge, it’s a matter of survival. Sounds familiar?

Adding to that is the growing impact of Artificial Intelligence. A warehouse that meets modern standards must be equipped with smart cameras using computer vision, IoT sensors, robotics, and Automated Storage and Retrieval Systems (AS/RS).

According to analysts, the AI in warehousing market is projected to reach $66.4 billion by 2030, with a compound annual growth rate (CAGR) of 26.8% from 2024 to 2032. This shows that companies are not merely experimenting with automation and warehouse AI integration, they’re actively implementing and scaling these solutions.

AI warehousing has swept away traditional management methods and technologies we once relied on. But are you ready for this new reality?

Let’s explore the advantages of adopting warehouse AI. Does your business truly need this transformation? What does the future hold, and how can you prepare for it without being left behind?

What Is an AI Warehouse?

An AI Warehouse is a storage system that leverages artificial intelligence and machine learning to perform operational tasks with minimal human intervention.

It can include fully automated processes like warehouse robotics, sorting, and movement - as well as smart recommendations for employees based on data analytics. For example: how to optimally arrange inventory, how much to reorder, or in which sequence to pick items.

Unlike a traditional warehouse that depends on human experience, paperwork, or basic rules (“if item X, store it in zone A”), an AI-powered warehouse:

- Analyzes where it's most efficient to store specific items in order to reduce order picking time;

- Autonomously improves processes - for example, by performing supply chAIn optimization;

- Learns from sales data, seasonal patterns, and trends to restock at the right time and avoid overstocking;

- Predicts rather than just reacts - it "sees" inventory levels and alerts you to potential stockouts before they happen;

- Minimizes the human factor by eliminating accounting errors, delays due to employee fatigue, and incorrect order fulfillment;

- Operates in real time.

The system might detect that products A and B are frequently ordered together and recommend storing them in adjacent bins, even if that contradicts the original inventory management logic.

For example, Amazon’s AI found that in regions expecting hurricanes, demand for baby formula and flashlights surged together. While people didn’t link these items, the algorithm saw a pattern: families with infants were preparing for outages. Now, when storms are forecasted, warehouses automatically store these items side by side, significantly speeding up order fulfillment.

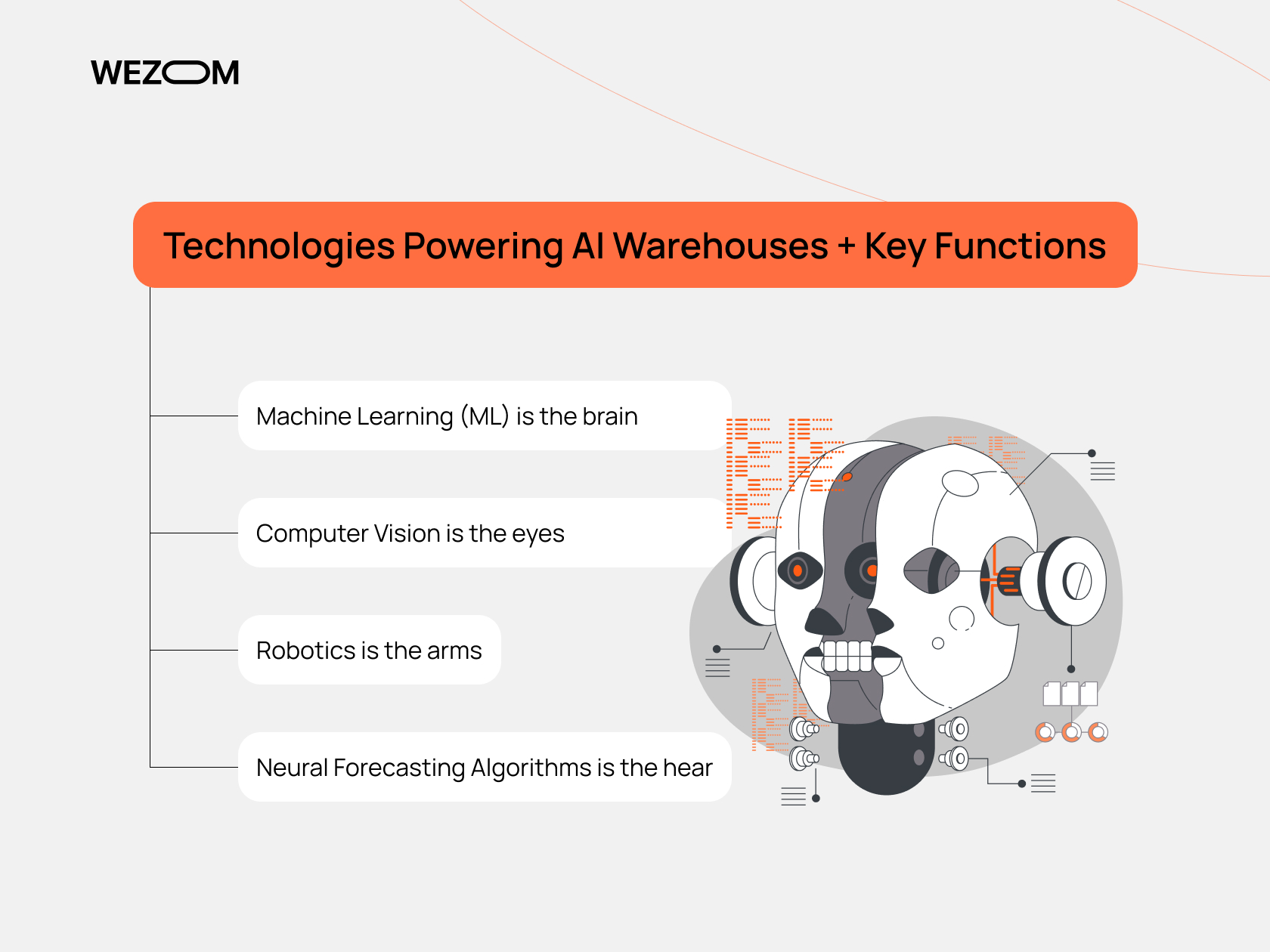

Technologies Powering AI Warehouses + Key Functions

AI does more than just enable warehouse automation, it can predict, adapt, and self-optimize thanks to these technologies:

- Machine Learning (ML) is the brain. Algorithms learn from historical data: what was sold, when, how fast, and what types of errors occurred.

- Computer Vision is the eyes. Cameras, sensors, tracking devices, and neural networks “see” what’s happening in real time: recognizing products, scanning pallets, monitoring staff actions, and ensuring quality control.

- Robotics is the arms. Robotic manipulators, automated forklifts, conveyor systems, autonomous drones, and more. These handle movement, order picking, scanning, and physical tasks.

- Neural Forecasting Algorithms is the heart. These models analyze seasonality, customer behavior, and demand trends to deliver actionable insights for warehouse optimization.

By integrating all of these technologies, Artificial Intelligence dramatically increases operational efficiency: routine tasks are delegated to machines, while human staff focus on management and handling exceptions.

10 Benefits of AI in Warehouse

1. Real-time stock visibility and accuracy

AI systems equipped with computer vision and RFID/sensor technology track every item 24/7, eliminating “blind spots.” For example, Zara uses AI to automatically update inventory levels as boxes are moved, reducing errors to just 0.1% - compared to 3–5% with manual tracking.

The benefits?

Fewer losses, fewer “dead zones”, and a much clearer understanding of what’s actually in stock.

2. Intelligent forecasting and demand planning

AI learns from historical data, seasonality, marketing campaigns, weather, even social media trends.

AI in warehouse management advised Walmart to increase popcorn stock 48 hours before major games. Fans were buying it early for home viewing. While managers focused on more “obvious” links (like beer), AI uncovered a non-obvious but highly valuable connection.

The benefits?

More accurate purchasing, no restocking chaos, and dramatically more efficient inventory management thanks to AI.

3. Reducing overstock and out-of-stock scenarios

Too much inventory? Your money gets tied up.

Too little? You risk losing customers.

Artificial Intelligence in warehouse management helps strike the perfect balance - identifying the optimal stock level for each SKU.

The benefits?

Improved inventory accuracy, fewer write-offs, and freed-up resources for other priorities.

4. Intelligent Automation in Warehouse Operations

AI sets priorities and optimizes logistics technology, including task assignments and routing for both staff and robots. For example, if an order is urgent, the system automatically adjusts the picker’s route to avoid delays. DHL implemented such a system and reduced equipment mileage by 40%.

The benefits?

Less manual management, faster order processing, and fewer mistakes.

5. Optimized powered picking, packing, and sorting

Computer vision and machine learning algorithms make it possible to recognize items, check for damage, select the optimal box size, and even suggest the ideal packing order.

The benefits?

Standardized packaging, reduced material usage, and fewer damaged goods.

6. Robotic automation and smart conveyors

Robots move pallets, boxes, and containers along AI-calculated routes. Smart conveyors “understand” what item is in front of them and automatically direct it to the appropriate zone - whether that’s receiving, packing, or shipping.

The benefits?

Less physical strain on staff, faster processing, and greater scalability.

7. Route optimization for internal logistics

An AI warehouse analyzes product placement, employee routes, traffic intersections, and zone congestion. Based on this data, it reconfigures internal logistics.

The benefits?

Fewer steps - and more orders fulfilled per shift.

8. Boosting Safety, Compliance, and MAIntenance

AI monitors compliance with safety protocols: wearing helmets, forklift routes, and employee behavior near hazardous zones. When deviations occur, the system triggers alerts or automatically halts operations.

The benefits?

Fewer workplace accidents and full compliance with OSHA and other safety standards.

9. AI-enabled surveillance and protocol monitoring

Computer vision cameras recognize actions in real time, such as theft, improper loading, or dropped cargo. This data is recorded and can be used for incident investigation or audit purposes.

The benefits?

Greater transparency, better control, and reduced losses.

10. Predictive mAIntenance of machinery and infrastructure

AI analyzes equipment behavior, including noise, vibrations, and load cycles, and alerts you to potential failures before they occur.

The benefits?

Fewer unplanned downtimes and lower maintenance costs.

Building Custom AI Solutions for Warehouse Optimization

Many companies begin building AI warehouses by using SaaS platforms - simple dashboards, template-based algorithms, and low-cost subscriptions. But as the business grows or operations become more complex, it becomes clear that standard WMS solutions with basic analytics:

- don’t adapt to specific needs - for example, unusual packaging (like medical devices or live plants) or specialized storage zones (such as multi-temperature warehouses);

- rely on generic forecasting algorithms that don’t understand your market, seasonality, or product mix;

- face integration issues - if you’re using a legacy ERP or custom logistics services, off-the-shelf software often requires expensive customization.

- lack flexibility - you can’t change business rules, add custom fields, adapt routing, or modify the user interface.

So how can you overcome these limitations? By developing custom warehouse order fulfillment software powered by AI, fully adapted to your specific workflows, inventory needs, and scaling strategy.

Yes, you need custom AI warehouse software if:

- Your warehouse operates with non-standard processes (e.g., hazardous materials, temperature-sensitive goods, or unique zoning layouts);

- Off-the-shelf systems don’t meet all your needs (frequent errors or downtimes occur);

- You’re facing integration issues: your current WMS, ERP, or CRM systems don’t support APIs for connecting robots or enabling real-time data analysis;

- You’re planning to scale, expand internationally, or significantly increase your SKU range;

- You understand that AI warehouse software development will pay off within 1–3 years.

No, you probably don’t need it if:

- You operate a small warehouse (fewer than 10,000 SKUs) with basic needs (inventory tracking and reporting);

- Ready-made WMS solutions (like SAP or Oracle) already cover 80% of your operations.

Key stages in developing AI-driven warehouse software

What steps should you expect when choosing custom AI warehouse software:

- Audit

Identify operational bottlenecks - for example, realizing that 40% of time is spent searching for products in chaotic storage. - Prototyping

Build an MVP for a single function, such as AI-driven forklift routing. - Training the Model on Your Historical Data

For instance, teaching the AI that demand for generators increases not only during hurricanes but a week beforehand. - Real-World Testing

Launch a pilot in one warehouse zone under actual working conditions. - Full-Scale Implementation + Integration

Seamlessly connect with your existing WMS, ERP, and logistics systems.

It’s crucial to note that AI-driven solutions require seamless integration with WMS, ERP, and TMS platforms, usually via APIs or middleware. For example, stock data from your ERP should feed into AI models for demand forecasting, with results automatically updating tasks in your WMS.

Support for multiple data formats (XML, JSON) and protocols (REST, SOAP) is vital for compatibility with legacy systems.

Scalability is another key factor, especially during peak seasons like Black Friday. Cloud infrastructure (AWS, Azure) lets your system scale resources and ensure 24/7 data access.

API interfaces also connect AI modules with equipment (sorting robots, conveyors) and third-party services (analytics, marketplaces).

As for the developer’s role in solving unique warehouse pain points, let’s quote a senior developer from the Wezom team:

“The core value of a warehouse AI developer is understanding your operations.

They must speak the same language as your logistics and warehouse teams, identify edge cases algorithms can’t ‘see’, and find practical compromises between real-world processes and machine learning capabilities.In my opinion, the ideal team is a trio: a business analyst, an ML engineer, and a system integrator.

Together, they create a solution that’s not just ‘nice to have’ - it actually solves real business problems.”

Want to learn more?

Get in touch with us - and we’ll build a custom system that’s fully tailored to your business goals and operational needs.

Case Studies: Real-World Use of AI in Warehousing

Vimaan has developed a system called StorTRACK, which leverages computer vision to automate cycle counting. The implementation of this technology at the Jaipur Living warehouse delivered the following results:

- A 40x increase in inventory counting speed compared to manual methods;

- A twofold improvement in inventory accuracy, reaching over 99% precision;

- A significant reduction in labor costs by automating the scanning and tracking of inventory.

Amazon's robotics-powered fulfillment centers. Amazon has actively adopted robotics in its fulfillment centers, significantly boosting operational efficiency:

- Over 750,000 mobile robots and tens of thousands of robotic arms now handle item movement and sorting tasks;

- Order fulfillment costs have been reduced by 25%, translating to up to $10 billion in annual savings by 2030;

- Order processing speeds have accelerated thanks to the integration of computer vision systems and Artificial Intelligence in warehouse management.

RetAIlers leveraging AI to streamline supply chAIns. Retailers are among the most active adopters of AI in warehouses. One notable example is Walmart, which achieved impressive results:

- A 20% reduction in excess inventory through more accurate demand forecasting;

- A 15% increase in order processing speed at distribution centers;

- Lower logistics costs due to AI-driven analysis of transportation flows and road conditions.

Challenges in Implementing AI in Warehouses

Implementing AI in warehouses comes with its own set of challenges:

- Data Quality and Completeness

AI requires large volumes of clean, structured data. However, many warehouses still operate on fragmented or outdated systems.

Solution: Conduct a data audit and begin phased digitalization. - Technical and Financial Barriers

Not all companies are ready to invest in the necessary infrastructure and integrations.

Solution: Use a modular approach: start small (e.g., with demand forecasting) and scale gradually. - Staff Training and Change Management

Employees may resist change or lack understanding of how to use AI systems.

Solution: Provide ongoing training, involve the team in the implementation process, and demonstrate real-world benefits.

The key is to treat AI adoption not as a one-time project, but as a strategic transformation.

The Future of AI Warehousing

The future of warehousing with AI lies in smart, self-regulating systems. Predictive modeling helps anticipate supply chain disruptions, weather impacts, and demand fluctuations, and adapt inventory in advance.

Digital twins - virtual replicas of warehouses and logistics routes - enable scenario testing without real-world risk.

This all forms integrated ecosystems where AI platforms seamlessly exchange data across WMS, ERP, transportation systems, and IoT sensors.

The result?

Maximum visibility, minimal costs, and the agility to respond to any challenge.

Conclusion: Preparing for the AI-First Warehouse Era

AI sees what humans consider random, and turns it into profit. Your warehouse is already generating hidden data patterns - time to start using them.

Start with a process and data audit: identify bottlenecks, prioritize automation areas, integrate AI into your WMS, and train your team.

In Warehouse Management, Artificial Intelligence is more than a technology - it’s a new way of thinking: to predict, optimize, and adapt.