Big Data and AI in oil and gas are among the prominent technologies that are now disrupting the industry with innovative methods. It gives businesses and business owners a huge potential to move forward and grow, but in order to reach these results, you need to know how this technology can be used, and why is it beneficial.

As in WEZOM, we are already experienced in creating robust and tailored solutions, we decided to talk about the use of technology, and different benefits that can be brought to businesses by big data analytics.

We are glad to introduce you into this topic, and for more information, please contact us so we can consult you on robust and suitable types of software that will help you make your business grow.

The future of Big Data in the oil and gas industry is promising, with the potential to drive efficiency, safety, and sustainability. However, realizing these benefits requires careful planning, investment, and a commitment to addressing challenges such as data security and integration. As technology continues to advance, the industry must adapt and evolve to stay competitive and environmentally responsible.

Let's examine the bright future of Big Data in the oil and gas industry, how it can be implemented, and its positive and negative effects on the field.

How Can You Benefit from Big Data in the Oil and Gas Industry?

Talking about technologies such as Big Data, as well as data science in oil and gas, there are various ways you can benefit from it, so it generally depends on your individual goals. However, there are several common ways Big Data may be beneficial for your organization.

Some of them are:

- You can manage seismic data

Drilling for oil in deep water can cost over $100 million, and it is crucial that you find the right location. In fact, to avoid any risks and save time and money, Shell uses fiber optic cables (created in a special partnership with Hewlett-Packard for these sensors), and the data is then transferred to its private servers, maintained by Amazon Web Services (AWS).

Upstream analytics begins with the collection of seismic data with sensors across a potential area of interest looking for petroleum sources. Then the data is aggregated, cleaned, processed, and analyzed to choose the best location for drilling.

- You can optimize the drilling process

Today's oil drilling platforms have about 80,000 sensors, which are expected to generate 15 petabytes of data during the lifetime of a platform. The large amount of data gathered by these sensors allows for predictive maintenance of equipment and timely replacements in order to reduce downtime and increase efficiency.

- You can improve reservoir engineering

Big Data solutions help oil and gas companies to collect, process, and analyze data that is essential for making reservoir production more effective. This data is collected using a number of downhole sensors (temperature sensors, acoustic sensors, pressure sensors, and others).

For example, with Big Data analytics companies can develop reservoir management applications to get timely and actionable information about changes in reservoir pressure, temperature, flow, and acoustics. That allows them to get more control over their operations and increase reservoir profitability.

- You can improve logistics

The oil and gas industry faces the problem of safely transporting petroleum. Sensors, predictive maintenance, and other technologies help detect any faults in pipelines or tankers (fatigue cracks, stress corrosion, seismic ground movements). This allows for safe logistics of petroleum products. Big Data also has many benefits for the oil and gas industry.

However, only 36% of companies have invested in Big Data analytics, and only 13% use it as an enhanced business intelligence solution. This shows that many companies still do not completely embed Big Data technology into their systems, but instead apply only part of it.

Big Data in the Upstream Oil and Gas Industry

Now, Big Data in the oil and gas industry, as well as the use of data analytics in oil and gas, have also reached the upstream segment. This technology is now commonly used by engineers for different applications and it benefits businesses in many ways.

As the amount of data in the oil and gas industry has increased and businesses now have to work with different volumes, the upstream sector of this field is now also affected by the use of Big Data. The high amounts of data in the industry make this technology even more important. Still, if a significant data set is used with sophisticated STEM tools, there are more patterns that can be recognized.

Big Data in the Downstream Oil and Gas Industry

When these companies sell oil and gas at the best price and use as few resources as possible to find customers, they benefit. If their product is more competitive, the likelihood of high profits increases. To make this so, these companies must make an environment-friendly commitment and apply IoT for price and asset monitoring.

The downstream oil and gas industry is undergoing a significant transformation due to the integration of Big Data technologies. The sector, responsible for refining petroleum products and delivering them to end-users, is leveraging Big Data in numerous ways to enhance efficiency and sustainability.

One key area of application is supply chain optimization. By optimizing logistics, tracking inventory levels, and improving distribution efficiency, downstream companies reduce operational costs while minimizing waste--thus ensuring that products reach customers in a timely manner. This streamlined supply chain not only enhances cost-effectiveness but also contributes to a more sustainable operation by reducing the environmental footprint associated with transportation and storage.

Just as with petroleum data analytics, the use of Big Data analytics can be instrumental in maintaining consistent product quality. By monitoring and controlling the refining process in real time, companies can ensure that their products meet stringent specifications and safety standards. This proactive approach not only minimizes the risk of product defects and recalls but also enhances customer trust and brand reputation.

Moreover, Big Data analytics enable predictive maintenance through IoT devices and sensors deployed in downstream facilities. By analyzing data from these devices, companies can anticipate equipment failures, enabling proactive maintenance actions that prevent costly unplanned downtime and extend the lifespan of critical assets.

The Key Challenges of Implementing Big Data in Oil and Gas

There are certain challenges that are commonly faced by those business owners who decided to use tools like Big Data and blockchain in oil and gas in their work. They include:

- Data transfer from the field to data processing facilities. This process creates issues for company owners in the field of oil and gas.

- The frequency of data collection is another problem. Also, the quality of collected data is equally important.

- In addition to that, you need a thorough understanding of the physics of the problem.

- And, finally, data quality and accuracy issues are among serious problems that are present in the industry.

To put it simply, implementing big data in the oil and gas industry presents challenges related to data transfer, collection frequency, data quality, and the need for a solid grasp of industry physics. Overcoming these obstacles is vital for maximizing the benefits of Big Data analytics in this sector.

Furthermore, the oil and gas industry faces the challenge of handling vast amounts of historical data accumulated over decades. This historical data, often in various formats and from different sources, needs to be integrated and made compatible with modern Big Data analytics systems. Ensuring that legacy data is accessible, usable, and valuable for current decision-making processes is a significant challenge for companies seeking to harness the full potential of Big Data.

Overcoming these data-related obstacles requires robust data management strategies, data governance frameworks, and investments in data infrastructure to facilitate seamless data transfer, ensure data accuracy, and enhance the overall data quality, ultimately leading to more effective decision-making and operational efficiency in the industry.

What You Need for Effective Big Data in Oil and Gas Solutions

There are certain recommendations that can help people know better how to build a robust solution using big data that would benefit the oil and gas industry. They include:

- You need to define KPIs – and the relevant business problem.

- Use physics-based data analysis in combination with big data methods.

- Keep the data structured and cleaned up. This will help you transform the data into insights.

To sum it up, to solve big data problems in the oil and gas industry, you need to accurately define the business problem and define key performance indicators. An addition, you must combine big data methods with physics-based data analysis, using an interdisciplinary team of computer scientists and petroleum engineers.

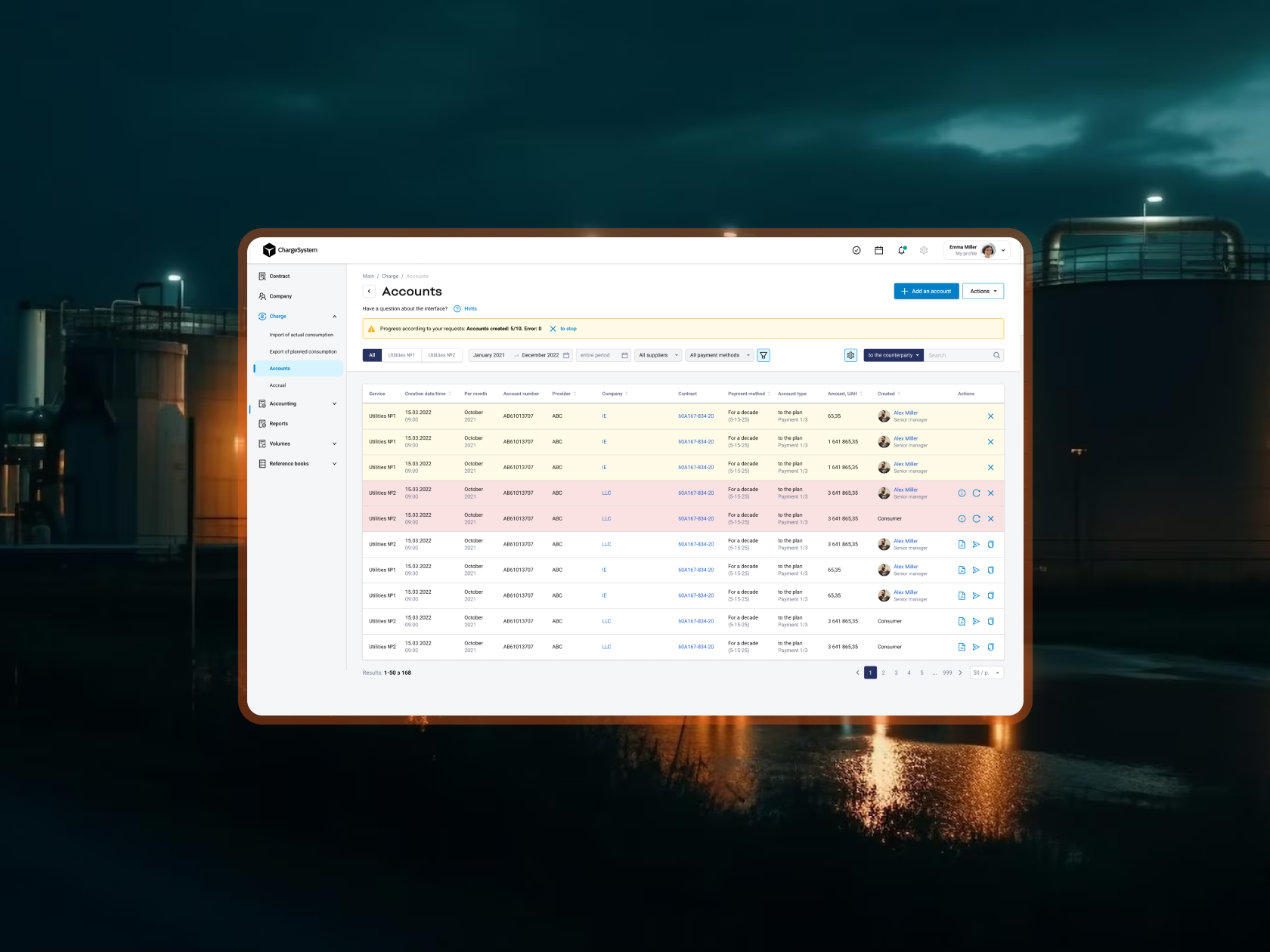

To make your work with big data successful, the data must be appropriately structured and cleaned up before it can be further transformed into insights, especially when dealing with accounting in oil and gas industry, where financial accuracy and compliance are critical. Also, the delivery of results as user-friendly interfaces account for around 80% of any big data analytics time.

Conclusion

Advanced analytics is developing at a rapid rate, with fully autonomous control systems for multifaceted processing facilities expected in the near future. This is based on the fact that more industry executives believe that Big Data is the solution to boost their business operations. Oil and gas industries that have adopted advanced data analytics are more likely to become industry leaders.

In addition, the integration of advanced analytics and the increasing reliance on Big Data are driving the oil and gas sector toward a future where fully autonomous control systems for complex processing facilities become a reality.

As industry executives increasingly recognize Big Data's potential to enhance operational efficiency, those companies that embrace and implement these technologies are positioning themselves as frontrunners in shaping the industry's future landscape. Consult us for more detailed information about Big Data and robust solutions that can make your work easier and help you grow your business. We choose an individual approach and assist you in your smallest needs.