Ever had that moment where you're running a fleet and suddenly realize you have no idea where half your trucks are? Or worse: you find out about a breakdown two hours after it happened because the driver's phone died?

Yeah, that's the nightmare we're trying to avoid here.

IoT fleet management combined with GPS fleet tracking systems has basically changed everything about how fleets operate.

In this article, we’ll explore how IoT and GPS fleet management systems are transforming logistics. You’ll learn how connected sensors, real-time monitoring, and predictive analytics help fleets operate smarter, safer, and more efficiently.

The Role of Connected Fleet Systems in Modern Transportation

Transportation ten years ago was basically a prayer and a hope. You'd send trucks out in the morning, maybe get a few check-in calls, and hope everything went smoothly. Problems? You'd find out when someone called from a gas station or (worse) when a customer complained about a late delivery.

Now we've got fleet telematics solutions that track everything: vehicle locations, engine performance, driver behavior, cargo conditions. This is logistics fleet monitoring in action, giving managers real-time insights to prevent delays, accidents, and equipment failures.

It evolved fast, honestly. GPS tracking felt revolutionary in 2015. Now? That's just the baseline. You can monitor dozens of data points simultaneously and get alerts before things break.

What kills me about the old way: reactive management. Everything happened after the problem. Engine overheated? Learn about it from a tow truck. A driver took a weird detour? Discover it during the monthly review. With real-time fleet monitoring sensors, you're catching issues as they develop (sometimes before they even become issues).

How IoT Fleet Management is Transforming Business Efficiency

The benefits go deeper than just tracking locations (though that's pretty great too). Smart fleet operations powered by IoT and telematics enable companies to optimize routes, reduce costs, and make data-driven decisions across their entire fleet. The market tells the story. The IoT Fleet Management Market is projected to grow from $11.2 billion in 2025 to $36.3 billion by 2034, and there's a reason for that explosive growth.

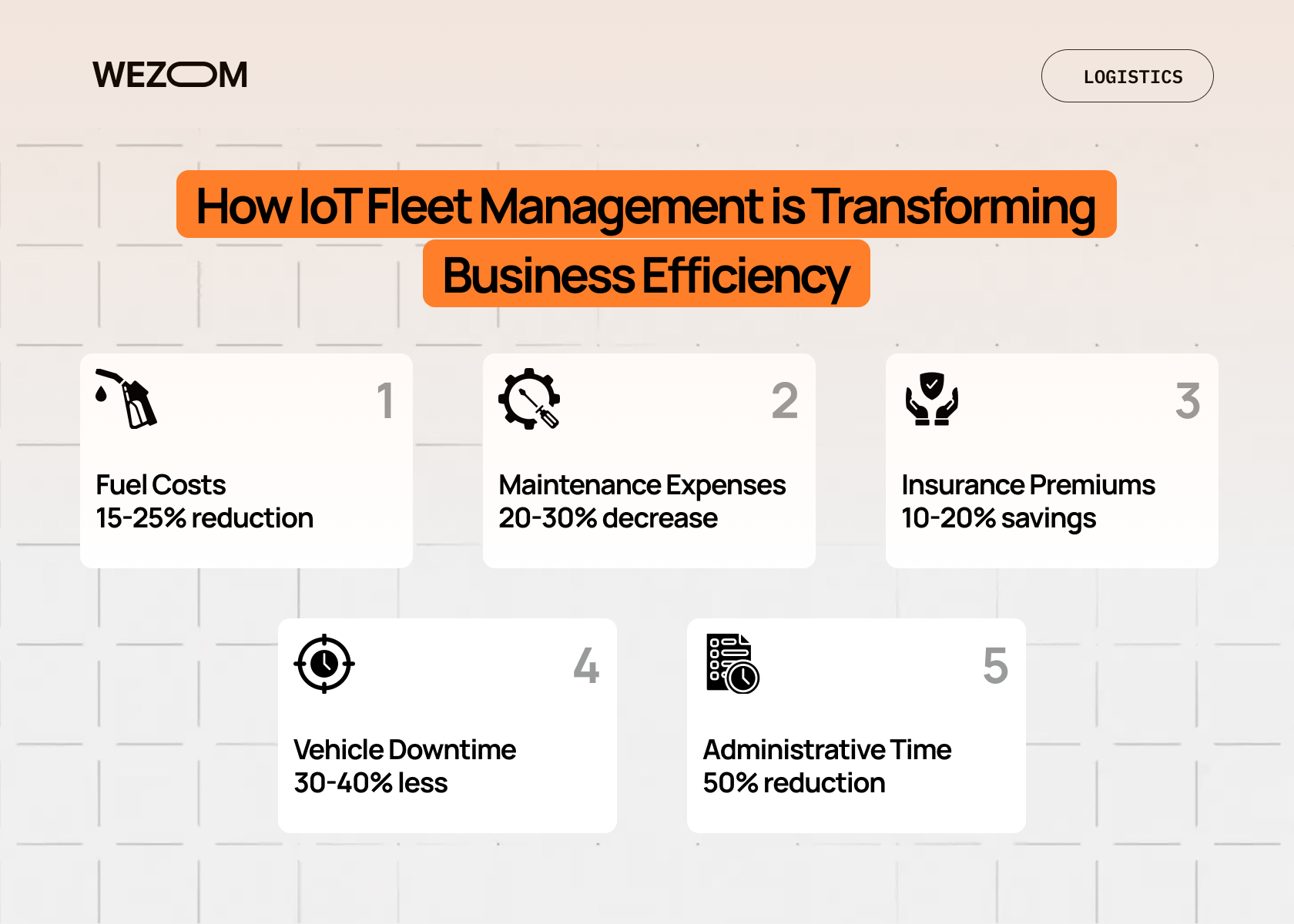

Cost savings hit you in unexpected places. Fuel consumption drops when you optimize routes based on real-time traffic. Maintenance costs fall when you catch issues early. Insurance premiums decrease when you can prove safe driving patterns.

| Benefit Area | Typical Impact | How It Happens |

|---|---|---|

| Fuel Costs | 15-25% reduction | Route optimization, idle time reduction, driver behavior coaching. |

| Maintenance Expenses | 20-30% decrease | Predictive maintenance, early problem detection. |

| Insurance Premiums | 10-20% savings | Documented safe driving, reduced accident rates |

| Vehicle Downtime | 30-40% less | Proactive repairs, better scheduling |

| Administrative Time | 50% reduction | Automated compliance, digital record-keeping |

Driver safety improves too. When vehicles have driver behavior monitoring systems, managers can coach based on actual data rather than guesswork. Hard braking, speeding, distracted driving — it all shows up.

GPS Fleet Tracking System: Core Features and Advantages

So what actually makes a GPS-based fleet solutions work?

Real-time location tracking is the foundation. Every vehicle transmits its position constantly (usually every 10-30 seconds). You see movement on a map, but you also get geofencing alerts when vehicles enter or leave designated areas.

Route optimization is where things get interesting.

"Optimizing routes and reducing the number of vehicles and kilometers driven can significantly lower fuel costs, contributing to both cost savings and sustainability efforts."

© Ivanka Vypasniak, Product Manager at HERE Technologies

The integration with telematics data analytics means you're not just collecting information, you're turning it into decisions. Which vehicles need replacement? Which drivers need training? Which routes are unprofitable?

Fleet Telematics Solutions for Smarter Operations

Telematics is basically the nervous system of your fleet.

Sensors collect data from dozens of points: engine diagnostics, GPS coordinates, fuel levels, door openings, temperature readings. That data flows to a cloud-based fleet telematics platform where it gets processed, analyzed, and turned into actionable insights.

Here's a real-world example: a logistics company using telematics and IoT integration reduced accidents by 40% in one year. How? By identifying risky driving patterns early and providing targeted coaching. The system flagged hard braking events, which often indicated distracted driving or poor route planning.

Real-Time Fleet Monitoring Sensors and Their Applications

There are more types of sensors than you'd think.

Vehicle health monitoring systems track oil pressure, brake wear, tire pressure (under-inflated tires waste fuel and create safety risks). Some monitor battery voltage, coolant temperature, exhaust emissions.

For refrigerated transport, real-time cargo condition monitoring is critical. Temperature sensors keep products in required ranges. Humidity sensors protect moisture-sensitive goods. Some systems even monitor light exposure or shock impacts for fragile stuff.

What makes these sensors valuable is the smart logistics and transportation IoT systems that interpret what the data means. A temperature spike might mean refrigeration failure. Or it might just mean the truck's sitting in the sun during a delivery stop. The system learns which is which.

IoT for Predictive Maintenance in Fleet Management

This is where things get really interesting (and cost-effective).

Traditional maintenance runs on schedules: change oil every 5,000 miles, replace brakes every 30,000. That's fine, but it's inefficient. You're either maintaining too early (wasting money) or too late (risking breakdowns).

Predictive maintenance for fleets uses IoT sensors for fleet vehicles to monitor actual component wear. The oil doesn't need changing at exactly 5,000 miles, it needs changing when sensors detect degradation in its viscosity and particle contamination.

The analytics look at patterns across your entire fleet. If transmissions typically fail around 150,000 miles, the system flags vehicles approaching that threshold for inspection.

Quick example: a delivery company noticed their vehicle tracking technology showed increasing fuel consumption on three trucks without obvious explanation. Predictive analytics suggested transmission issues. Inspections confirmed early-stage problems. Repairs were scheduled during low-demand periods, avoiding three potential breakdowns during peak season.

That's the power of seeing problems before they escalate.

Security and Data Privacy in Connected Fleet Systems

Now, here's something people don't talk about enough: all this connectivity creates vulnerability.

Fleet management software with IoT is collecting sensitive information: vehicle locations, driver identities, delivery schedules, customer addresses. If someone hacks in, they could steal trucks, cargo, or data.

IoT cybersecurity in fleet management needs multiple layers. Encrypted data transmission between vehicles and servers. Secure authentication for accessing the system. Regular software updates to patch vulnerabilities.

Compliance matters too. Depending on where you operate, you might need to follow GDPR, CCPA, or industry-specific regulations. Drivers have privacy rights even when they're on the clock. You need clear policies about what's monitored, how data is used, and who can access it.

Future Trends in Connected Fleet Technologies

So where's this all heading?

AI-powered fleet management tools are getting smarter. Machine learning algorithms can now predict not just mechanical failures but optimal driver assignments, demand fluctuations, and even fuel price trends.

Autonomous vehicles are coming (slowly, but coming). We're already seeing autonomous fleet management systems for closed environments (warehouse yards, mining operations, port terminals).

Sustainability is a big push. Energy-efficient fleet tracking systems help companies reduce carbon footprints by optimizing routes and identifying vehicles that should be replaced with electric alternatives.

5G connectivity will transform real-time capabilities. Current systems update every 10-30 seconds. With 5G, we're talking near-instantaneous data transmission. That enables things like real-time video streaming from vehicles and vehicle-to-vehicle communication for coordinated operations.

Conclusion

Managing a fleet without connected technology in 2025 is like running a business without email. Can you do it? Sure. But why make life harder?

Fleet visibility in real time is about making smarter decisions faster, catching problems before they cascade, running operations that are safer, more efficient, more profitable.

The technology's here. It works. And honestly, it's getting better every year.

Your competitors are probably already using this stuff. Just saying.

FAQ

What industries benefit most from connected fleet solutions?

Almost everyone running vehicles, honestly. Delivery and logistics see huge gains. But so do construction firms, utilities, emergency services, public transit, field service businesses. Got vehicles? This helps.

How accurate are GPS fleet tracking systems in real-time monitoring?

Modern GPS hits 3–5 meters under good conditions. Urban canyons or heavy trees? Maybe 10–15 meters. For fleet management, that's plenty. You're not landing planes—just need to know which street the truck's on.

Can IoT sensors detect driver fatigue or unsafe behavior?

Some systems can. Advanced driver behavior monitoring systems use cameras and AI to spot drowsiness—eye closure rates, head position, yawning. Others monitor driving patterns like lane drifting or erratic speeds. Not perfect, but getting better.

What are the biggest challenges in implementing fleet telematics?

Cost is obvious (ROI usually comes within 12–18 months though). Driver acceptance can be tricky—nobody loves feeling watched. Integration with existing systems sometimes gets messy. And there's a learning curve for managers to actually use the data instead of drowning in reports.

How does IoT for predictive maintenance differ from traditional maintenance?

Traditional maintenance follows fixed schedules. IoT-driven predictive maintenance uses sensor data to assess real conditions, triggering service only when performance drops or anomalies appear.

Are real-time fleet monitoring sensors compatible with existing systems?

Most modern solutions offer integration through APIs. Older vehicles might need aftermarket sensors, but those usually plug into standard OBD-II ports. The fleet tracking hardware and sensors have gotten pretty universal.

What role will 5G play in the future of fleet connectivity?

5G enables faster data transmission with lower latency. More detailed real-time monitoring, better video capabilities, and eventually vehicle-to-vehicle communication for coordinated driving. Think trucks that convoy automatically or get instant warnings about hazards from vehicles ahead.