The content of the article:

Vehicle maintenance is an essential part of the transportation business as nobody wants to endure professional risks and losses due to poorly maintained equipment. Keeping your vehicles well-maintained is also necessary for avoiding potential dangers for drivers as well as ensuring all of the services are provided in a proper way.

For a transportation firm owner, poor vehicle maintenance is a serious problem as it creates unnecessary expenses and challenges. In the long run, it may bear serious financial risks. Breakdowns occur regularly but there are proven ways to prevent them by using technology and effective strategies.

Let’s have a look at what exactly is fleet management software and how it helps perform preventive and predictive vehicle servicing for the success of your transportation business.

Types Of Maintenance

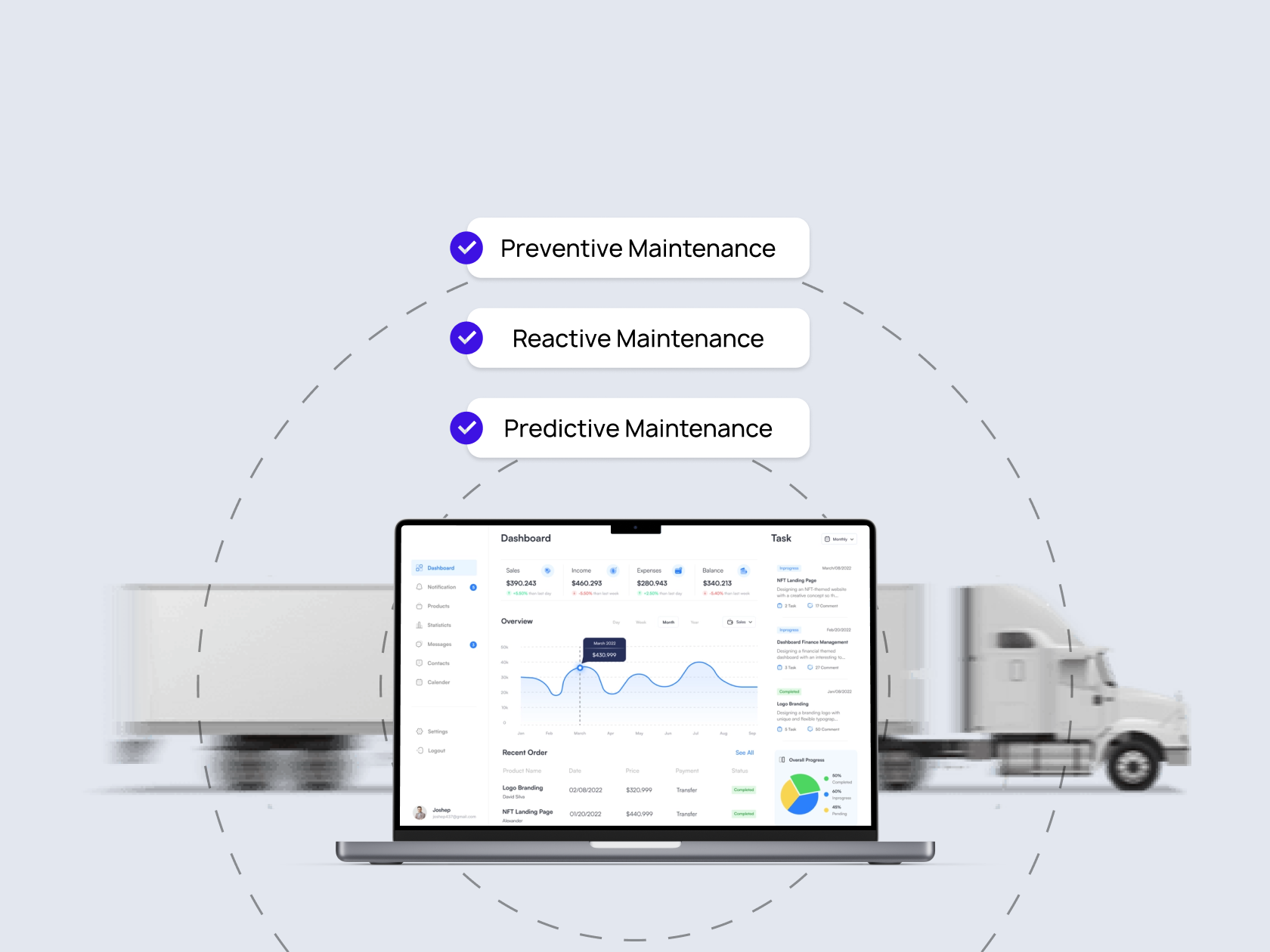

As maintenance is an important aspect of successful work of a transportation firm and poor treatment of vehicles can create serious additional issues for your business, there are three main approaches to maintenance that are centered around different goals, namely reactive, preventive and predictive types of maintenance. Each requires a set of measures and technical assistance. Different approaches allow you to fix breakages differently, but you need to choose thoughtfully as the process of maintenance affects your whole workflow.

As the names imply, they are focused on measures for predicting and preventing breakages or dealing with them after their occurrence. All of the three approaches have their advantages and disadvantages, so it is important to know the details about each one as some of them require serious investments. Also, before attempting serious measures, you need to know what resources you have and is it necessary to implement complex strategies.

The main difference between the approaches is that preventive and predictive methods of maintenance are proactive. Thus, by making the right steps, business owners can significantly enhance their process of maintenance and reduce the chances of damage, while reactive maintenance is often considered risky and expensive.

Reactive Maintenance

The method of reactive maintenance generally implies repairing damage after it has been done. Such an approach is considered to be less costly due to reduced expenses on support maintenance, but it usually overlooks that repair works sometimes take even bigger amounts of money. Also, you don’t need to make plans on monitoring and checking the state of equipment so this strategy seems less energy-consuming and more convenient. The way of dealing with breakages after their occurrence often leads to unnecessary safety risks and low efficiency of repairing works.

If you don’t want to build a strategy of preventive measures or invest in software that will allow you to monitor the state of vehicles, a reactive maintenance strategy may just be the right fit. However, it has its own specific characteristics that can increase risks and even dangers for drivers as you don’t know the potential type of damage. Also, repairing trucks is a difficult process and you need to be prepared financially.

Preventive Maintenance

The concept of preventive maintenance is that you have a plan consisting of regular maintenance activities so that you are prepared for potential problems. Also, these measures help prolong the lifespan of vehicles and equipment. Although there is always a chance of breakage, a risk-preventive strategy allows you to save money and reduce dangers at the beginning. You can still face breakages but the preventive method of maintenance guarantees that you are able to detect them and take measures to ensure safety.

Although usually serious planning is required, preventive maintenance increases the potential vehicle efficiency and allows you to have everything under your control. As you already know the bad trends in the beginning, it is far more convenient for you to enhance your maintenance strategy and avoid risks.

Predictive Maintenance

Predictive maintenance implies predicting possible breakages and monitoring the state of your equipment but not having a structured plan of maintenance activities. This way, the possible issues are addressed beforehand. A system of measures often saves you resources that you need to involve in case of dealing with breakage after it happens, and minimizes risks due to constant monitoring of the equipment, but it takes time and effort to do everything correctly. This method of maintenance is considered highly effective, but also costly.

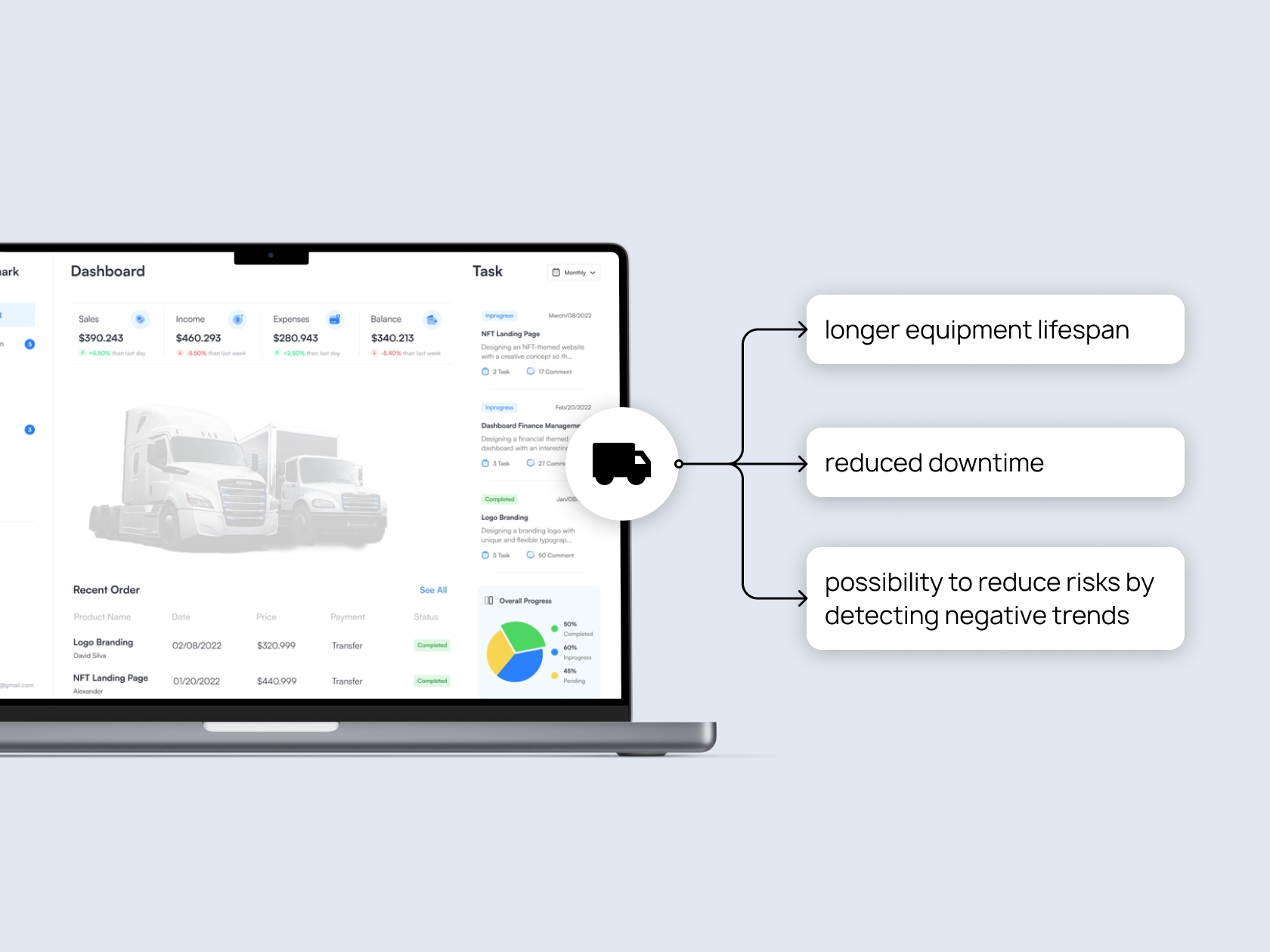

Among the benefits predictive maintenance strategy can bring to your business, there are the following:

- longer equipment lifespan;

- reduced downtime;

- possibility to reduce risks by detecting negative trends;

and so on.

This type of maintenance requires a serious set of measures, such as involving IoT and machine learning technologies, investing in vehicle maintenance software, hiring IT professionals, and so on. You need to build an ecosystem consisting of technology and professional help. In order to predict possible damage, you also need to collect and analyze the necessary data.

How Can Software Help?

Both predictive and preventive maintenance requires the substantial use of software as there are a lot of measures that need to be taken in the process of taking care of vehicles. The software simplifies complex processes and makes effective monitoring possible.

There are different requirements in these two approaches so you may need different technologies to meet them. Let’s have a look.

Software For Preventive Maintenance

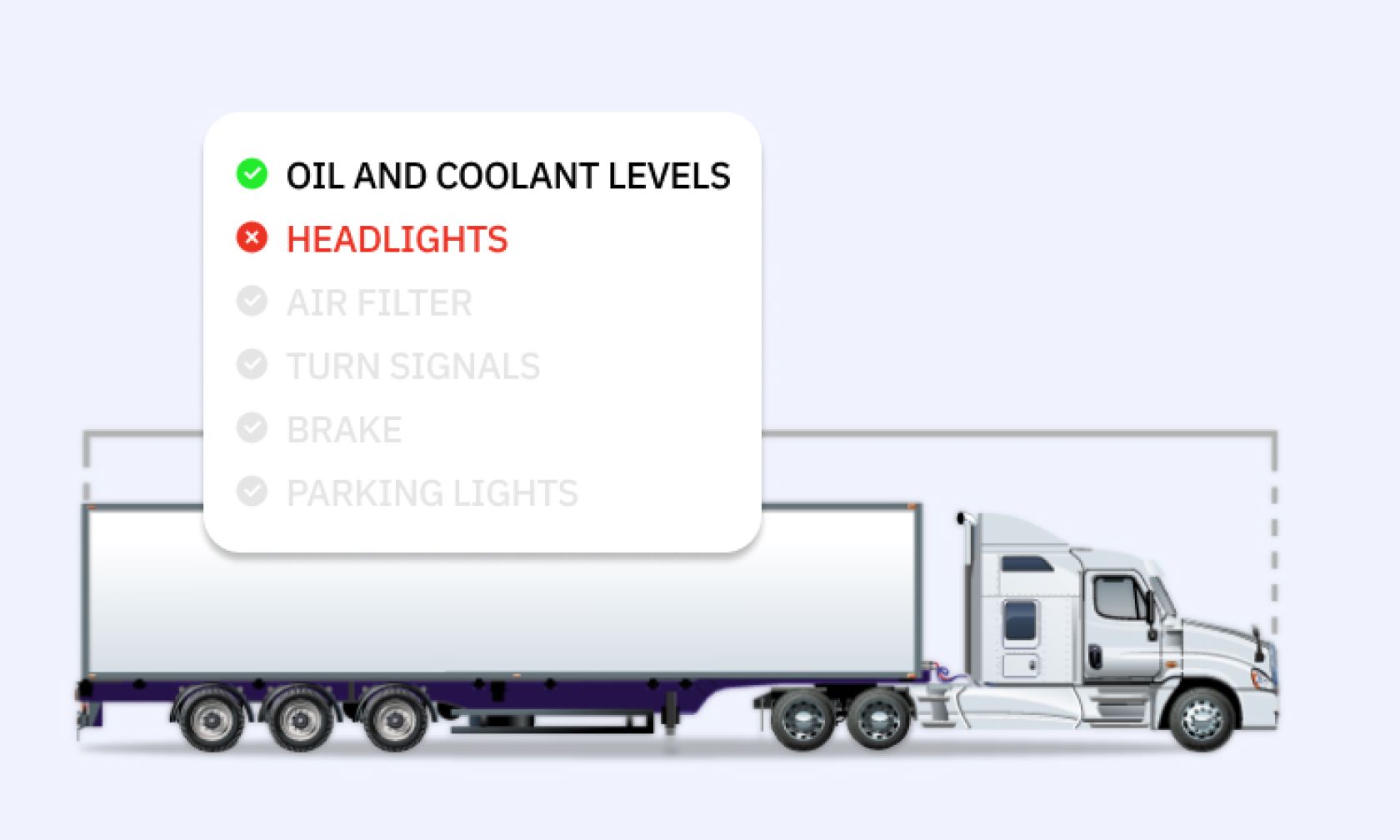

Preventive maintenance requires constant inspections and measures that are aimed at keeping vehicles well-maintained. This means you need to have control over the state of equipment. Fleet management systems, as well as fleet maintenance software, offer a range of features that help management, monitoring, and prevention of possible breakages.

Both types of maintenance software provide specific measures for assisting your preventive management strategy, but you may use them in different ways. As fleet maintenance software helps you do regular maintenance checks, you may spend less time fixing damages as you are already in control of the situation. Also, minimized paperwork and repetitive tasks allow you to spend more time on effective tasks rather than performing the same activities over and over without much productivity. Some of the main features for preventive maintenance these types of software offer are the following:

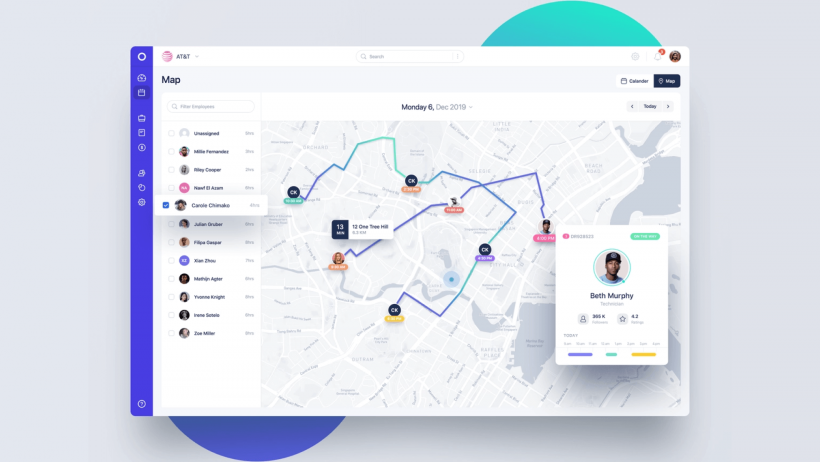

- vehicle tracking;

- inventory management;

- fleet management;

- reporting and analytics;

and so on.

Reporting and analytics are important as getting a clear picture of what’s happening and you get comprehensive data. Without clarity in reporting you are not able to have a complete picture of your vehicle maintenance.

Software For Predictive Maintenance

The main goal of the predictive method of maintenance is to take measures before breakage occurs. Utilizing truck fleet maintenance software in this approach is not easy as you need a fully-functioning infrastructure in order to ensure general efficiency. IoT technologies used to collect and transmit data help you in monitoring processes. Although a robust system of measures needs to be created, this method is believed to be one of the most effective.

Predictive maintenance software usually requires serious investments but it also allows you not to spend many resources on monitoring vehicles on a regular basis, as in preventive maintenance, and not to be at risk by fixing damage after it has already occurred.

Conclusion

Proper vehicle maintenance is important to any company as it saves you money, and allows you not to be bothered with your vehicles most of the time. Poorly maintained vehicles are unreliable and they cause a range of problems and expenses. Apart from many losses, you may put your services and even drivers’ lives at risk. Besides that, accuracy is the key to helping your business grow as you eliminate serious problems by taking various small details into consideration.

In order to keep things neat, you must pay attention to multiple details, and technology can help you do this. With multiple complex tasks that are required in the process of proper vehicle maintenance, you need strong digital support. Combining different tools and making use of your own skills will help you to create a powerful strategy for keeping your vehicles well-maintained and efficient. Also, monitoring the behavior of drivers allows companies to make the best use of the equipment and prevent the patterns that lead to breakages. You may significantly minimize risks for your equipment by adopting a proven strategy of maintenance and using technology to ensure vehicle efficiency and low risks.

Fleet maintenance software helps save time and money, reduces vehicle downtime, and helps you organize your process of maintenance. Without this handy tool, you will have to manage multiple processes by yourself and not have time for truly important assignments. Streamline your process of work with the help of software and be sure that your vehicles are well-maintained and efficient.