Computer devices have long learned to cope with tasks that were previously only possible for humans. Smart machines control space stations, cars, medical equipment, etc. They turn on the lights, translate text, and can even perform some creative tasks.

All this has been made possible thanks to advances in artificial intelligence (AI). It understands language commands, can learn, can respond to speech, and perform many other actions. There are different AI technologies. One of them is machine learning (ML).

The oil and gas sector is undergoing a rapid transformation with the introduction of machine learning, an emerging field that has the potential to transform exploration and production methodologies. Its scope includes analyzing seismic data, well logs, and various geological data sets to facilitate the discovery of potential oil and gas deposits.

Machine learning algorithms excel at analyzing production data and identifying patterns that, when used, optimize performance, resulting in increased productivity and reduced downtime. Moreover, this analytical prowess serves a dual role: identifying potential hazards, assisting in proactive incident prevention, and enhancing operational safety. Below, we will consider in more detail the issue of introducing machine learning in the oil and gas industry.

Machine Learning in Oil and Gas

We can divide machine learning in the oil and gas industry into three categories: extracting knowledge from data, predictive analytics for forecasting and planning, and data-driven production optimization. Below, we will take a closer look at these three aspects of ML in oil and gas.

- Extracting information from data is critical. Enormous amounts of information are accumulated in the oil and gas sector. However, this information, stored in logs or computer programs, is of limited value. Machine learning allows you to process this data, draw conclusions, and make decisions to determine the company's development prospects.

- Predictive analytics in planning and forecasting is also relevant for oil and gas companies. Using past data, such as the production history of a particular well or seismic survey results in a specific region, companies can use machine learning to predict future events. For example, suppose a company has data on how oil production from wells varies during different periods of the year. In that case, machine learning can predict production volumes in subsequent years. These forecasts can be used for long-term planning to make the oil and gas company's operations more profitable.

- Data-driven production optimization is crucial for oil and gas companies that extract fuel from the ground. The efficiency of this process is of high importance. Machine learning allows companies to analyze their data to identify the best practices for organizing production. This can include various aspects, from determining the optimal spacing of wells to making drilling site decisions and testing different hydraulic fracturing techniques.

These three areas demonstrate how machine learning helps make better decisions today and allows companies to plan for the future by analyzing past data. This becomes critical in overcoming the challenges associated with improving workflow and adapting to new technological challenges.

Why is Machine Learning so Important?

Machine learning has revolutionized the oil and gas industry by helping companies gain the information they need and find ways to interact with customers. ML recognizes customer behavioral characteristics and action patterns. In addition, machine learning can be used in many areas, such as image, face, speech recognition, computer vision, and email filtering.

What Is the Difference Between AI and Machine Learning?

Society is accustomed to the fact that artificial intelligence and machine learning are synonymous, but ML is a subset of AI in oil and gas. In particular, machine learning is algorithms and technologies that allow systems to improve themselves, make decisions, and identify patterns based on data and experience. As for artificial intelligence, globally, computers can imitate human thinking and perform various tasks under appropriate conditions. At its core, software developers use machine learning in areas such as computer vision, time series forecasting, and natural language processing.

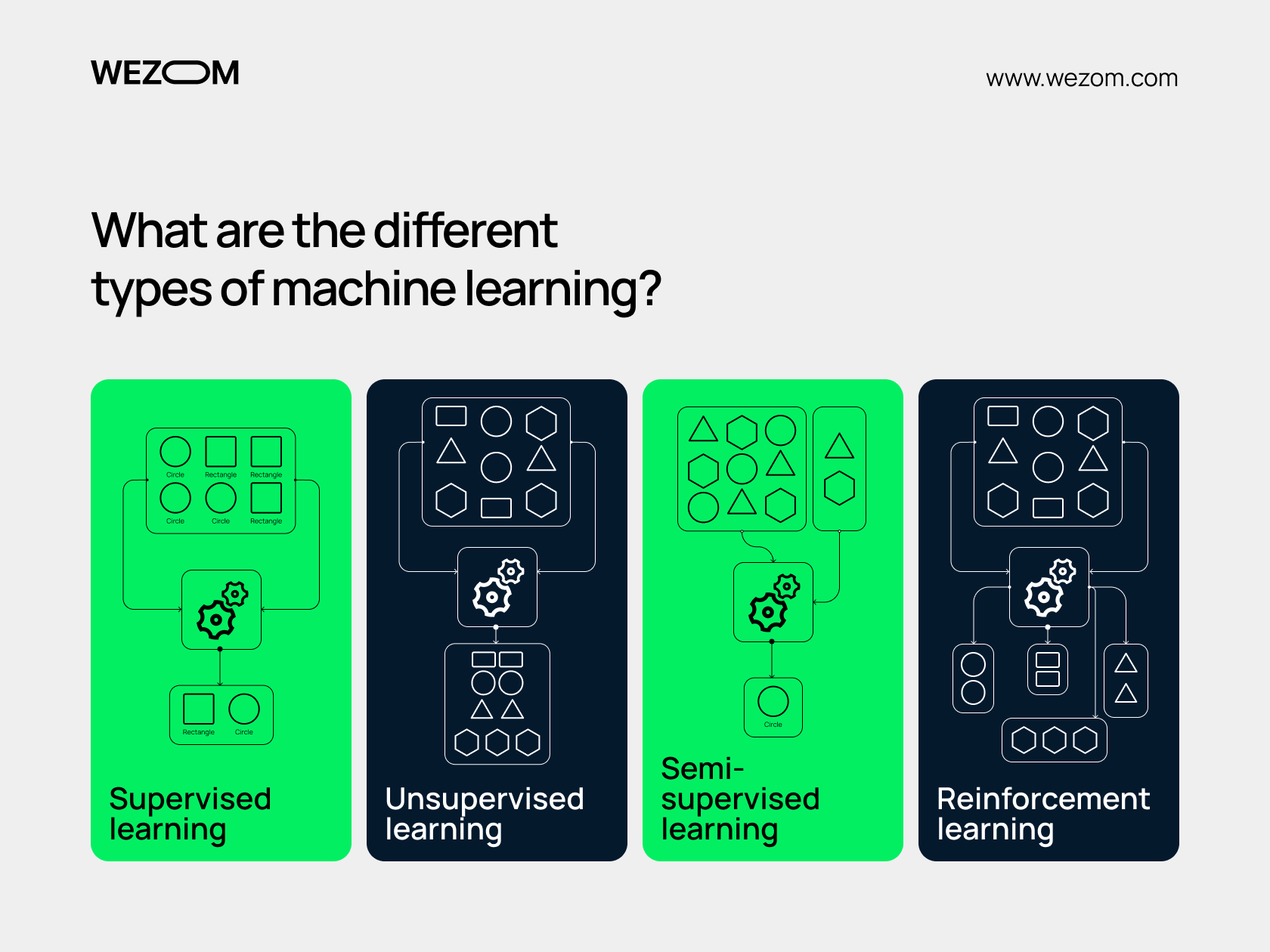

What are the Different Types of machine learning?

Now let's look at what types of machine learning exist and are used in the oil and gas industry.

Supervised learning

Supervised learning involves training a model using a labeled dataset, where inputs and corresponding outputs are provided. This machine learning method utilizes training examples, collectively known as training data.

By iteratively optimizing an objective function, supervised learning techniques develop a function capable of predicting outputs for new inputs. The algorithm is deemed proficient at a task when its output or prediction accuracy improves over time. Supervised learning algorithms can be broadly categorized into two main types: Classification and Regression.

Unsupervised learning

Unsupervised learning algorithms examine input-only data sets to discern patterns, such as grouping or clustering of data points. Unlike supervised learning, this method operates on unlabeled data, identifying commonalities within the data and making decisions based on their presence or absence in each new data point without relying on explicit feedback. In unsupervised learning, the model autonomously learns from the data. These algorithms are commonly employed for clustering, anomaly detection, association mining, and dimensionality reduction.

Semi-supervised learning

This approach combines elements of both supervised and unsupervised learning. Data scientists provide a limited amount of labeled training data to an algorithm, enabling semi-supervised learning. The algorithm assimilates information from the labeled data and can independently explore the dataset and make its own conclusions.

Reinforcement learning

Reinforcement learning is an approach data scientists employ to instruct machines on accomplishing tasks within complex and uncertain environments. In this method, artificial intelligence tackles problems resembling game scenarios, utilizing trial and error to find solutions. The computer receives rewards or penalties based on its actions, guided by the programmer's objectives, aiming to maximize the overall reward.

What software development can We Offer for Machine Learning in Oil & Gas?

ML can make life easier for many companies in the oil and gas industry. One of the many machine learning use cases in oil and gas is using programmed equipment to perform routine tasks automatically. Considering that vast data sets accompany such tasks, you can program ML to analyze them to maximize efficiency. Next, we will examine the cases in which machine learning can be used.

Upstream Services

Thanks to machine learning, oil and gas companies no longer need wildcatting, as ML allows them to find fields to launch a well and improves the methodology for gas and oil production. Machine learning technology offers upstream solutions and allows for predictive analysis, oilfield operations, improving drilling efficiency, optimizing drilling rigs, allowing timely risk detection, and much more. Thanks to the speed of data analysis, ML can cope with all assigned tasks many times faster than a human.

Midstream Services

Machine learning can also improve the delivery of oil and gas from fields to processing plants. You can develop midstream energy software that will simplify the product's gathering and transportation, calculate the shortest and most profitable logistics routes, and recommend laying optimal pipelines. Considering that mining algorithms instantly cope with massive data flows, you can maximize your business's efficiency at all stages.

Downstream Services

Machine learning algorithms are a universal tool that can improve the efficiency of literally all processes in the oil and gas industry. Thus, creating downstream software will allow you to optimize the return and processing of raw materials, carry out remote systems operations, and analyze all risks. Given that you can't hire enough employees to watch every part of your chain, machine learning will be able to absorb information that will allow it to make informed decisions to help your employees.