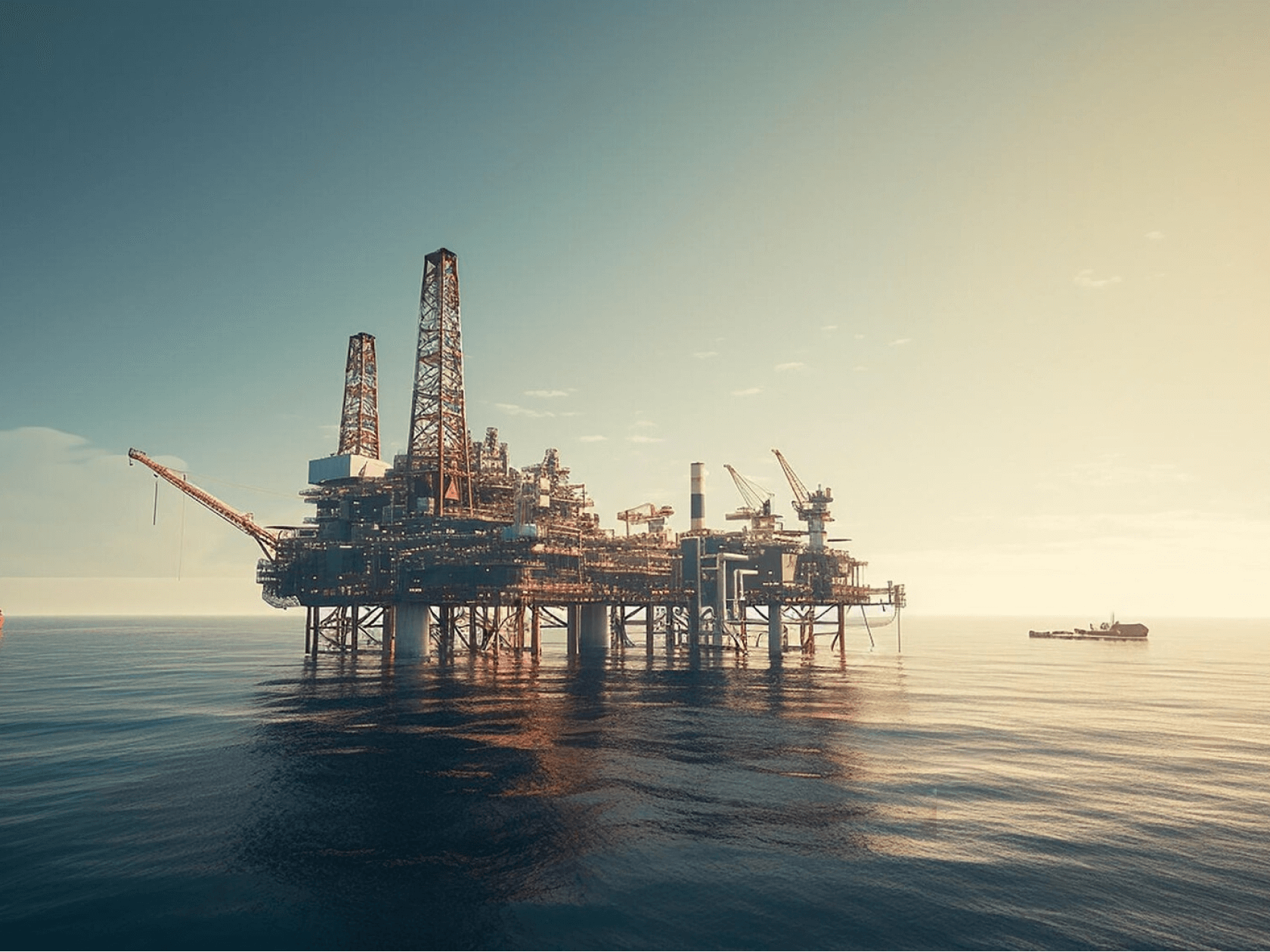

IoT has many ways of implementation in the oil and gas industry, including collecting, transferring, and analyzing raw data in real time. This helps companies to have more valuable information about the different processes.

In the oil and gas industry, the Internet of Things can be used to manage operations and optimize processes, strengthening project management in oil and gas industry workflows. One advantage is predictive maintenance. By using sensors to monitor equipment such as drilling machinery, pipelines, and storage tanks in real time, companies can detect potential issues before they lead to costly breakdowns. This proactive approach will reduce downtime and save substantial maintenance costs.

Furthermore, IoT solutions enhance safety by enabling remote monitoring of hazardous environments, ensuring that workers are not exposed to unnecessary risks. In summary, IoT's transformative potential in the oil and gas sector extends far beyond data management, making operations more efficient, cost-effective, and safer.

WEZOM team has already proven itself to be helpful for those companies that are willing to get the most out of IoT. We know how to implement this technology for completely new business results, and we gathered some information considering the aspects you need to know in your work.

As a tool, the IoT in the oil and gas industry brings many benefits to the field and empowers professionals and business owners to make progress by using these advantages. But How exactly do the internet of Things and IoT solutions help the industry, and what to expect when using it? In this article, we will shed some more light on the use of IoT technology in the industry of oil and gas, the practical aspects of this phenomenon, and the ways it can improve businesses.

Let’s have a look.

The Importance of IoT in the Oil and Gas Sector

Of course, innovative technologies play a hugely important role in modern businesses, but this is not the only way they affect professional processes. Technologies, and solutions that are based on these technologies, are a way to achieve more, have better results, and optimize certain processes. But how?

In this dynamic industry where remote and harsh environments are the norm, IoT-enabled sensors provide real-time data on equipment performance, environmental conditions, and safety parameters.

This data enables companies like WEZOM, known for exceptional expertise in software development, to develop advanced monitoring systems. These systems help in optimizing production processes by monitoring reservoirs and pipelines for maximum resource extraction while ensuring the reliability of critical equipment.

Additionally, WEZOM’s innovative solutions have been instrumental in reducing downtime and maintenance costs for businesses operating in challenging environments.

Advantages of IoT in the Oil and Gas Industry

The adoption of Internet of Things (IoT) technology in oil and gas has brought about a multitude of advantages, revolutionizing the way companies operate in this sector.

Sensors and connected devices are deployed throughout oil and gas facilities, allowing for real-time monitoring of equipment and processes. This data-driven approach enables companies to detect anomalies, predict equipment failures, and optimize maintenance schedules--leading to reduced downtime and lower operational costs. Additionally, IoT facilitates remote monitoring and control--reducing the need for on-site personnel in hazardous environments and improving safety conditions for workers.

The Internet of Things can help to improve both safety and environmental sustainability within the oil and gas industry. By monitoring environmental conditions, such as air quality and water levels, companies can respond more rapidly to potential leaks or spills. This helps prevent accidents and minimizes the impact that operations have on the environment. Furthermore, integrating IoT into oil and gas operations promotes both operational excellence and an environmentally responsible approach.

Utilizing IoT Capabilities in Oil and Gas Enterprises

Leveraging the capabilities of the Internet of Things (IoT) has become increasingly integral to the operations of oil and gas enterprises. IoT technologies, such as sensors and connected devices, offer real-time data collection and monitoring capabilities across remote and critical infrastructure.

These innovations enable companies to enhance their asset management, optimize production processes, and improve safety measures. By harnessing IoT in oil and gas, enterprises can attain greater operational efficiency, reduce downtime, and make data-driven decisions, ultimately resulting in cost savings and increased competitiveness in this dynamic and resource-intensive industry.

The Role of IoT in Exploration and Production Processes

The oil and gas sector is rapidly adopting IoT technology to transform exploration and production processes. Forward-thinking companies are shifting their focus from using IoT devices like sensors to developing innovative strategies for leveraging the data these devices collect, creating smarter business models for greater success.

In seismic data acquisition and analysis, IoT-enabled sensors provide real-time insights into subsurface structures, accelerating exploration and improving reservoir modeling.

In drilling operations, IoT integration optimizes efficiency, reduces costs, and enhances safety through real-time monitoring and predictive maintenance. Overall, IoT is revolutionizing the oil and gas industry by streamlining processes and improving decision-making.

IoT in Action: Pipeline Monitoring and Maintenance

In the realm of pipeline monitoring and maintenance, IoT (Internet of Things) technology is reshaping industry practices. IoT devices are strategically placed along pipelines, continuously collecting data on parameters like pressure, temperature, and flow rates. This real-time data transmission to a central control system allows for careful monitoring and control of different essential aspects, as well as for rapid issue response, which will reduce the risk of downtime and environmental damage.

Additionally, machine learning algorithms enable predictive analytics, forecasting maintenance needs, and optimizing resource allocation, illustrating practical applications of machine learning in oil and gas that make pipeline management smarter, more efficient, and environmentally responsible.

Our Expirience

Our client, a prominent player in the oil and gas sector with a network of 17 offices, approached us with a pressing need to streamline, optimize, and accelerate their internal business operations. The intricate and interrelated nature of their processes posed a unique challenge, as off-the-shelf solutions available in the market couldn't adequately address their specific requirements.

Additionally, certain departments within the organization faced difficulties in achieving seamless synchronization among their existing tools. Recognizing the need for a tailored solution, our client made the strategic decision to embark on a custom development journey, seeking a comprehensive and efficient solution that would revolutionize their internal workflows.

If you're interested, check out the article below!

Refining and Processing: How IoT Makes a Difference

In the field of refining and processing, the integration of IoT (Internet of Things) technologies has ushered in a transformative era. IoT devices are deployed throughout refining and processing facilities, monitoring critical parameters, such as temperature, pressure, and equipment performance, in real time. This constant data collection enables operators to make informed decisions swiftly, optimizing production processes, enhancing safety, and minimizing downtime.

Moreover, IoT technology plays a pivotal role in the refining and processing industry by continuously monitoring equipment and processes. This real-time data enables proactive decision-making, enhances operational efficiency, and reduces downtime, resulting in substantial cost savings. By providing a data-driven foundation for decision-making, IoT is revolutionizing the refining and processing industry, making it more agile, cost-effective, and sustainable.

IoT's Impact on Oil and Gas Logistics and Distribution

As IoT use cases in the oil and gas industry show, IoT (Internet of Things) technology is making a big difference in how the oil and gas industry handles logistics and distribution. It's like having smart sensors and trackers on trucks, pipelines, and storage tanks, allowing companies to keep a close eye on their assets in real time. This helps them move goods more efficiently, save on fuel, and manage their logistics better.

IoT also plays a crucial role in keeping oil and gas shipments safe. It can quickly detect problems like leaks or changes in temperature that might lead to accidents or environmental harm. By catching these issues early, IoT helps prevent disasters and costly delays. In short, IoT is revolutionizing how the oil and gas industry handles its logistics, making it safer and more efficient.

Obstacles in Adopting IoT in the Oil and Gas Industry

Obstacles to implementing IoT solutions in the oil and gas industry include:

- Data Security and Privacy: IoT systems handle sensitive data, necessitating robust cybersecurity measures to protect information and ensure compliance.

- Integration with Existing Systems: Integrating IoT with legacy systems can be complex and time-consuming, requiring a thorough understanding of current infrastructure and a well-planned implementation strategy.

- High Initial Costs: Deploying IoT solutions often involves substantial upfront investments in hardware, software, and infrastructure upgrades, necessitating a careful evaluation of ROI and long-term benefits.

- Talent and Skill Gaps: Finding skilled IoT professionals with expertise in IoT, security, hardware, and user requirements can be challenging due to the rapid growth of the IoT market, potentially increasing project costs and resource constraints.

Implementing IoT solutions in the oil and gas sector is a promising endeavor but not without its challenges. Key obstacles include ensuring data security and privacy, integrating IoT with existing systems, managing high initial investment costs, and addressing talent and skill gaps.

Overcoming these hurdles requires a strategic approach that emphasizes cybersecurity, careful planning, cost-benefit analysis, and talent acquisition. Successfully navigating these challenges can unlock the substantial benefits that IoT technology offers in streamlining operations and enhancing efficiency within the industry.

Transforming Your Oil and Gas Operations with IoT

Embracing IoT technology holds the promise of creating a safer and more sustainable future within the energy sector. By leveraging IoT, manual maintenance tasks are reduced, complex processes are automated, and environmental hazards are minimized, marking a significant shift in the industry's approach.

Just as in the case of AI in oil and gas, IoT's transformative impact on oil and gas is unmistakable. It empowers the sector to monitor and manage its infrastructure with precision, optimizing resource allocation and minimizing downtime.

We are always glad to help if you need more information about the transformative power of IoT. We will take into account all of your individual needs and specifics and will carefully analyze them to align them with market trends to achieve maximum effect and provide a highly competitive solution within your budget.