Automation and organization of work are the basis of excellent professional performance. Without proper organization, you will be overwhelmed with the amount of work to do. If you have numerous repetitive tasks in your warehouse that take a lot of time and effort, it will distract you from major work aspects and will not give you the desired result.

That is why warehouse automation is becoming increasingly popular. It is a multi-level procedure that allows you to organize the way your warehouse works and no longer do large amounts of routine work. Repetitive and tedious manual work is not just ineffective, it is also hard and increases the chances of human error.

This is why warehouse automation is not only an opportunity to make progress in the efficiency of the company but also a necessity for basic productivity. This includes both the involvement of machines and the software that performs management tasks. With a large amount of work to be done manually, you can easily get overwhelmed with duties without completing the necessary assignments, so good organization is essential for general business performance.

If you want to achieve maximum efficiency in working with a warehouse, but do not want to spend too much time and money on it, and also if your profit depends on it, warehouse automation technology will help you reach a new level of productivity. Besides that, automation is used to increase the level of security in the company, which affects its business performance and reputation.

From drones and robots to purpose-built digital solutions, there are a plethora of ways to make your job easier and help you be more productive, improve safety, increase employee satisfaction and make your delivery faster. In this article, let’s try to find out how businesses can benefit from different types of warehouse automation and how this process is applied in transportation companies.

What is Warehouse Automation?

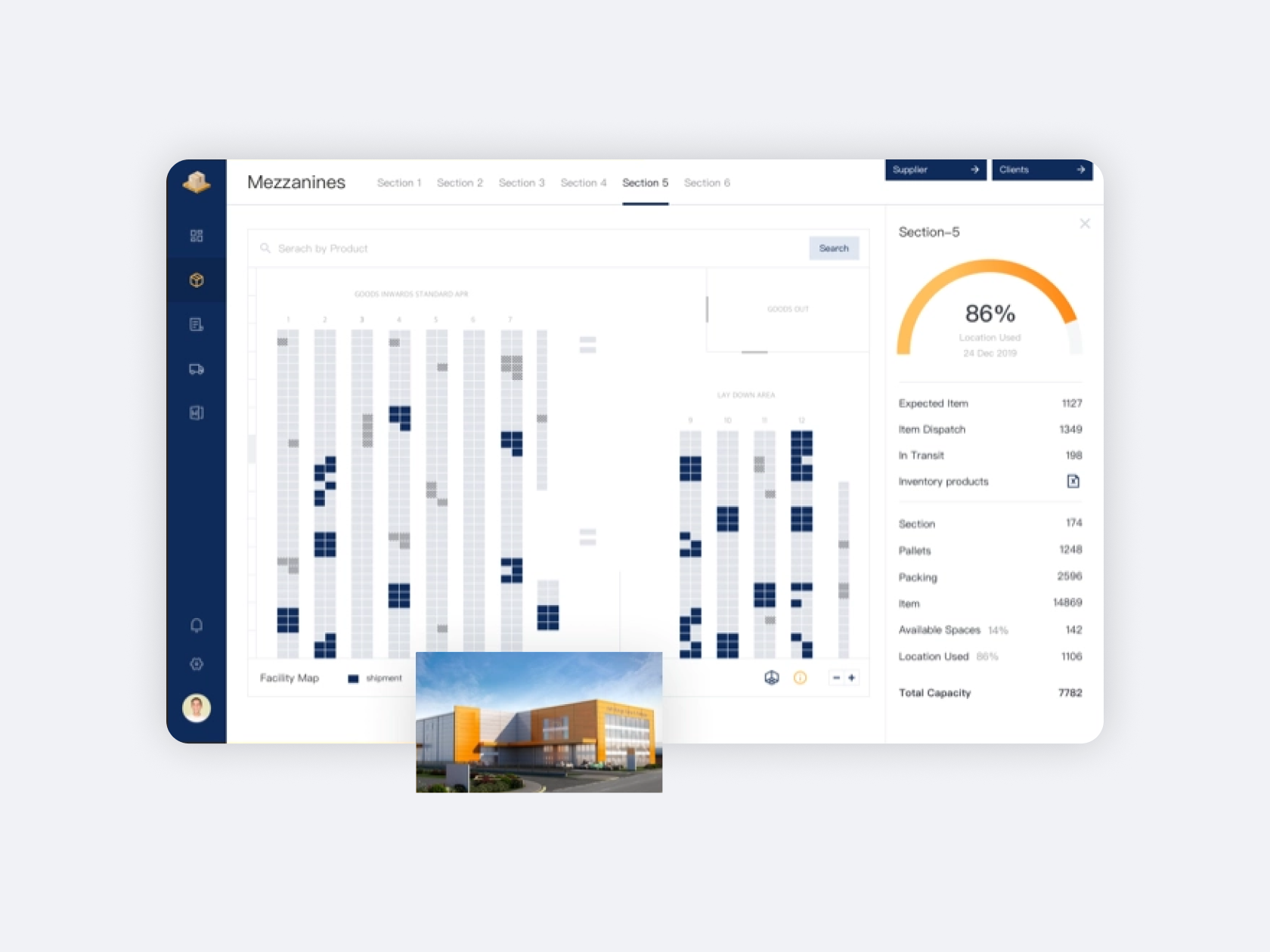

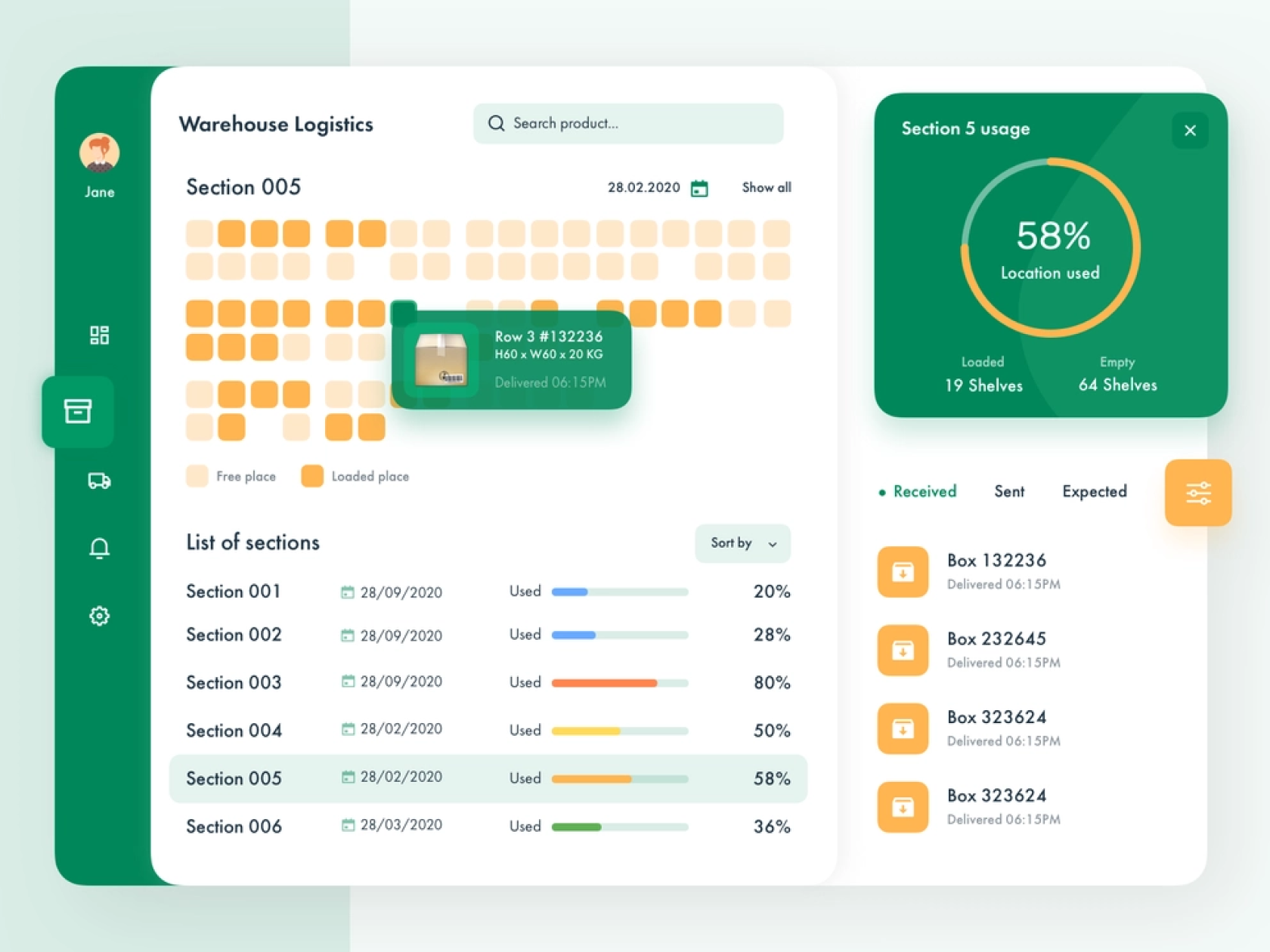

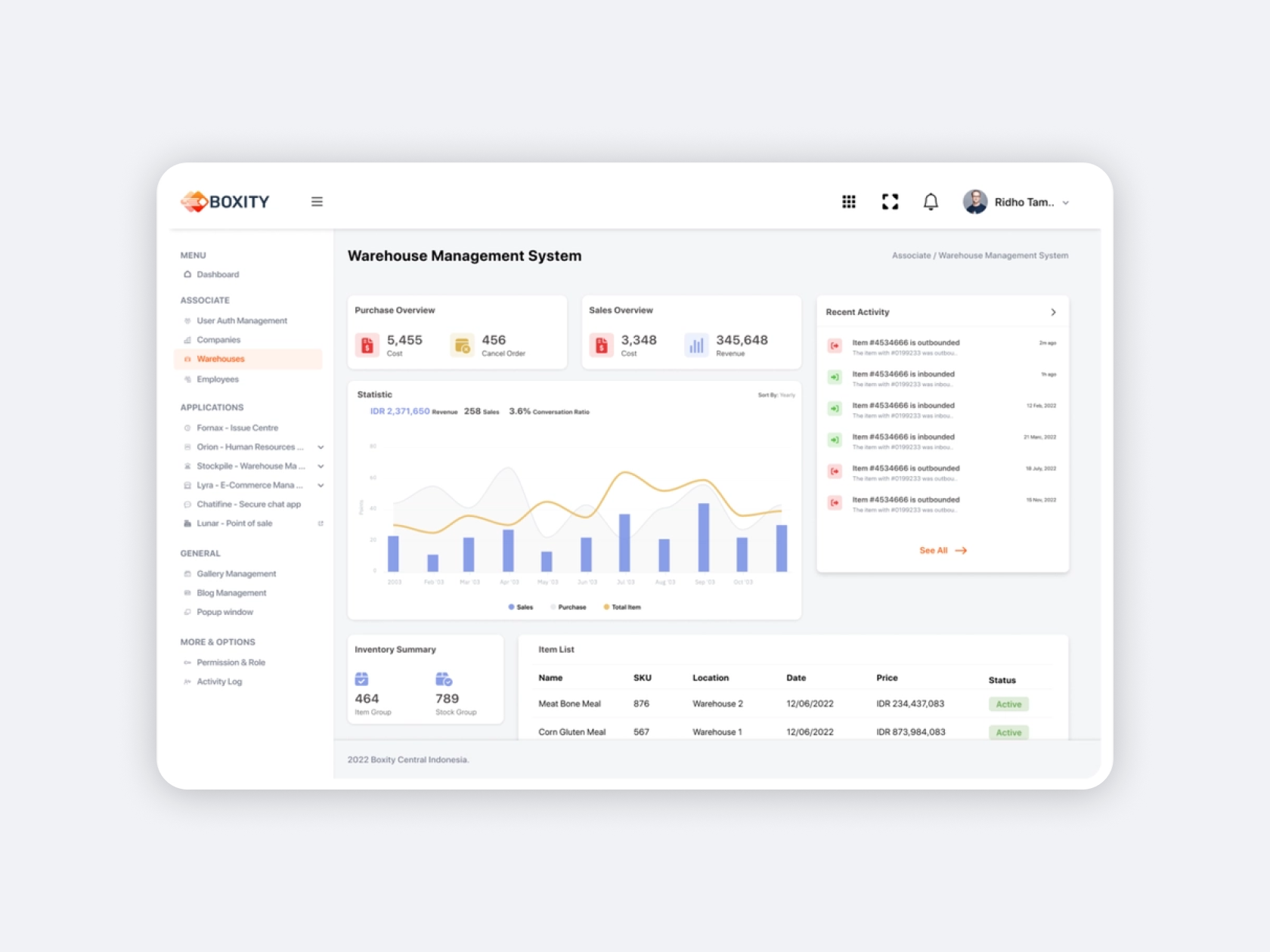

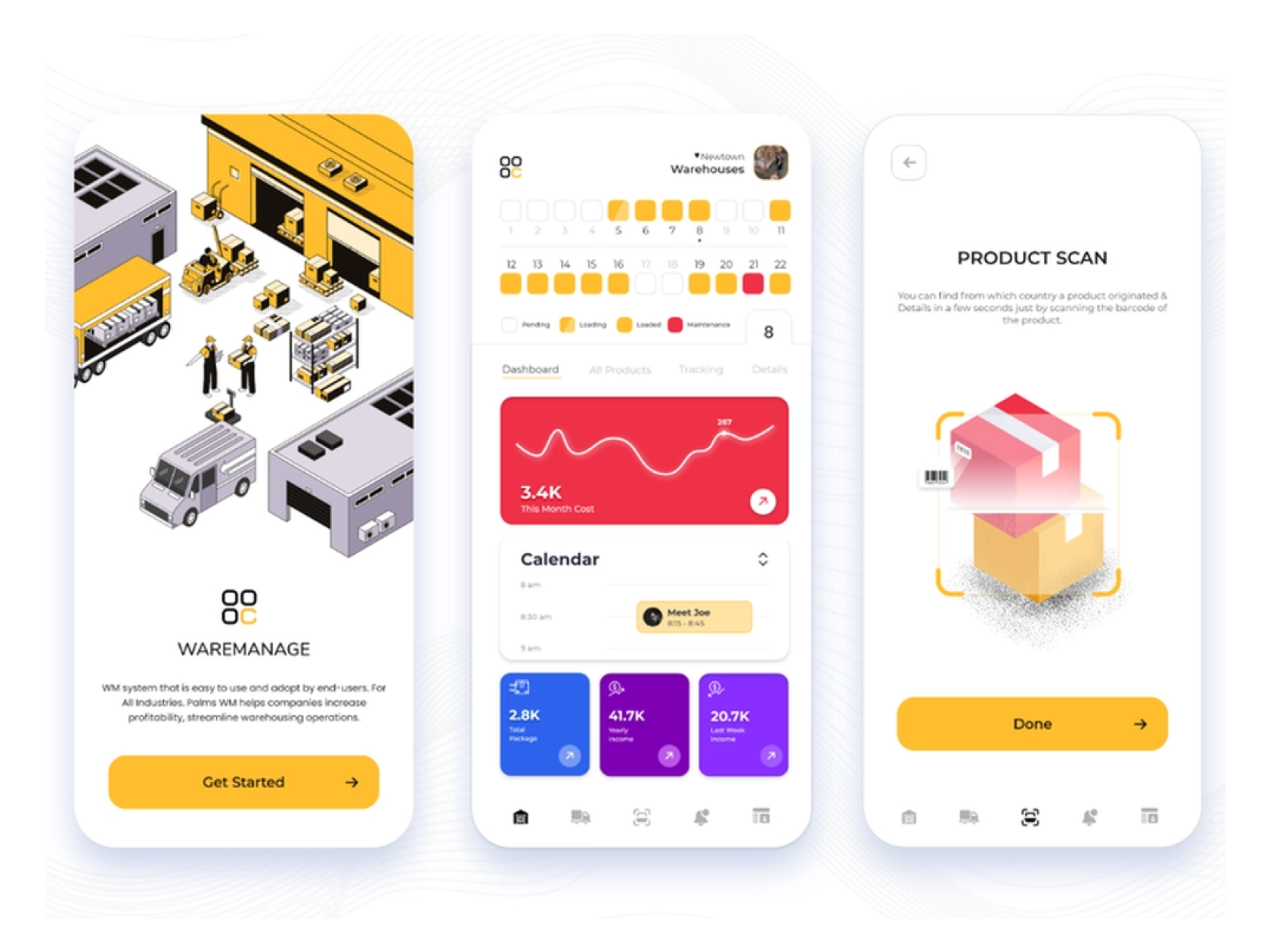

Warehouse automation is a process that consists of many levels and will allow you to introduce technology into your warehouse management. The combination of your people's work and technology solutions will allow you to skillfully solve difficult problems and achieve better results where automation and the use of more modern solutions are needed.

In simple terms, warehouse automation is the method of replacing numerous manual processes that are usually carried out by employees with the involvement of technology solutions. This method can be applied with the help of robots or software, as nowadays in its progress automation has gone a lot further than robotics.

Automation is often used in those work areas where you need a lot of effort, or where you need employees to enter significant amounts of data. Automation is also often applied in areas where data analysis is required. In general, there are tasks with a huge amount of data, where you just need to automate processes, so technology may be vital.

Also, this approach can be helpful if you need to improve the efficiency of processes. Automation can involve storage, equipment, and retrieval systems, as well as warehouse automation solutions. Technologies like drones and software can positively affect general warehouse management.

What is an Automated Warehouse?

Although the term «warehouse automation» is often used to describe the use of robotic tools for improving the efficiency and accuracy of warehouse tasks, sometimes, it is just about software, even though the field of robotics has developed significantly to meet the needs of warehouse automation.

In fact, there is a distinction between physical and digital automation. Although robotic technologies may assist significantly in repetitive tasks and enhance performance, the software helps cover a massive amount of work by minimizing labor-intensive processes. Digital solutions save employees from exhausting hours of tedious work and free them up to deal with more complex and important tasks. In simple words, the combination of software and a large amount of collected and analyzed data make it possible to automate and organize strenuous tasks. This approach also allows for minimizing human errors which can affect efficiency.

Technological assistance combined with human effort is generally far more effective than manual repetitive work. Tools like drones and robots allow us to not only do bigger amounts of work but also to automate processes and organize workflow. Since both hardware and software are utilized in the processes that constitute warehouse automation, and there are different tasks that need various technological approaches, let's take a look at what types of automation there are and how they work for increasing efficiency and organizing the workflow.

Types of Warehouse Automation

Since warehouse automation is focused on different company needs and includes various processes, there is a range of ways it can be applied. Today, technological innovations allow you to cope with multiple problems and perform various tasks effectively, and you no longer need to take on large amounts of work yourself.

Since there are tasks that require a special investment of time and effort, the use of some modern technologies is already a necessity, and you can significantly improve some aspects of your work if you wisely use the tools that technological progress gives us. Warehouse automation is divided not only into physical and digital automation but also into different methods using various tools that can help with increasing efficiency. Here are some of them:

Goods-to-person technologies

Goods-to-person or GTP technology refers to the method that uses robots and machines to bring materials to employees so they can assemble and pack them. Using machine labor and physical labor is very effective, as proven by research. This kind of solution involves automated storage and retrieval solutions that use vehicles, carousels, and cranes for moving and storing goods, as well as conveyor systems, which are the old variation of warehouse automation technologies.

With the help of goods-to-person solutions, you can not only shorten the delivery time which is a significant bonus for client satisfaction but also minimize human errors and improve safety.

Pick-to-light Systems

Pick-to-light systems assist specialists to find the proper things to fulfill orders with the help of barcodes and LED lights. This technology allows workers to locate goods faster, thus enhancing productivity and general performance. Pick-to-light solutions are convenient and intuitive, they are designed for multiple purposes. They are effective in reducing the number of human errors because there are models that can determine the correctness of the selection and notify in case of an error.

Collaborative Mobile Robots

Nowadays, the introduction of robotic technologies in the automation of warehouses is becoming more frequent, as this approach has proven itself to be efficient. Collaborative mobile robots are designed to assist workers in various assignments, all of which are essential for the quality work of the warehouse. These tools are flexible as they can handle a variety of tasks.

Also, collaborative mobile robots are considered very efficient as combined with the work of employees, they are 85% more effective than humans and robots working separately. These robots work accurately and precisely, locating, picking, and delivering objects as the task requires.

Drones

In warehouse automation, drones powered by algorithms and connected to warehouse management systems serve as an effective inventory management tool. Some drones also have visual sensors and barcode scanners for tracking inventory and automating processes.

How Can Companies Benefit from Warehouse Automation?

There are a lot of ways technology can make our work easier and help us gain more profit. Warehouse automation is a powerful tool to replace big amounts of tedious work with efficient and fast technical assistance, but the benefits of this method do not end there. Robots and software not only get the job done in a short time without losing efficiency, they are versatile and can handle many tasks. In addition to efficiency, the accuracy of completing tasks is also growing.

Among the main warehouse automation benefits, there are:

- improved productivity and efficiency;

- high accuracy;

- minimized manual labor;

- space optimization;

- increased worker satisfaction;

- optimized space;

and so on. Besides that, automating work and increasing productivity helps you perform multiple tasks easily and effectively, without losing the quality of your work, and it will help the company grow and profit. This is an important aspect, as, with the help of automated warehouse systems, you will get rid of a large amount of routine work and will be able to focus on more essential and rewarding elements of work.

Safety is another major benefit for any business as safety affects the success of your company and the efficiency of your work. Using warehouse automation software and the ability of robotic tools to work for a long time, you can significantly increase the level of safety in your company. Space optimization helps to maximize and productively use the available space in the warehouse and not clutter it up. It is an important aspect if you have a large warehouse. With this action, you can more easily organize your work, use the warehouse efficiently, and monetize more cubic feet.

Conclusion

Nowadays, as technological advances change business every day, digital solutions and technological tools can help us in many different and unusual ways. By automating your warehouse, you will get a lot of free space that you can use efficiently, increase safety and security and reduce the chance of human error. All of these factors affect your performance, help you gain profit, and improve your professional reputation.

Also, aspects like reduced labor costs and improved employee satisfaction affect your business in a positive way. By applying modern and convenient technological solutions, you will save a lot of important resources and be able to achieve much more significant results in terms of efficiency, which, of course, will have an influence on the financial aspect.

So, by using robotic tools and software in your work with a warehouse, you will easily cope with your tasks and will be able to move forward if you can effectively use technological solutions. After all, profits and better performance depend, in particular, on the implementation of large-scale tasks. The whole technological field is developing rapidly, and innovations are constantly stimulating progress in various areas of business, so companies also need to keep an eye on this aspect in order not to stand still. Automate your warehouse and be able to keep up with market-changing technologies.

What is warehouse automation?

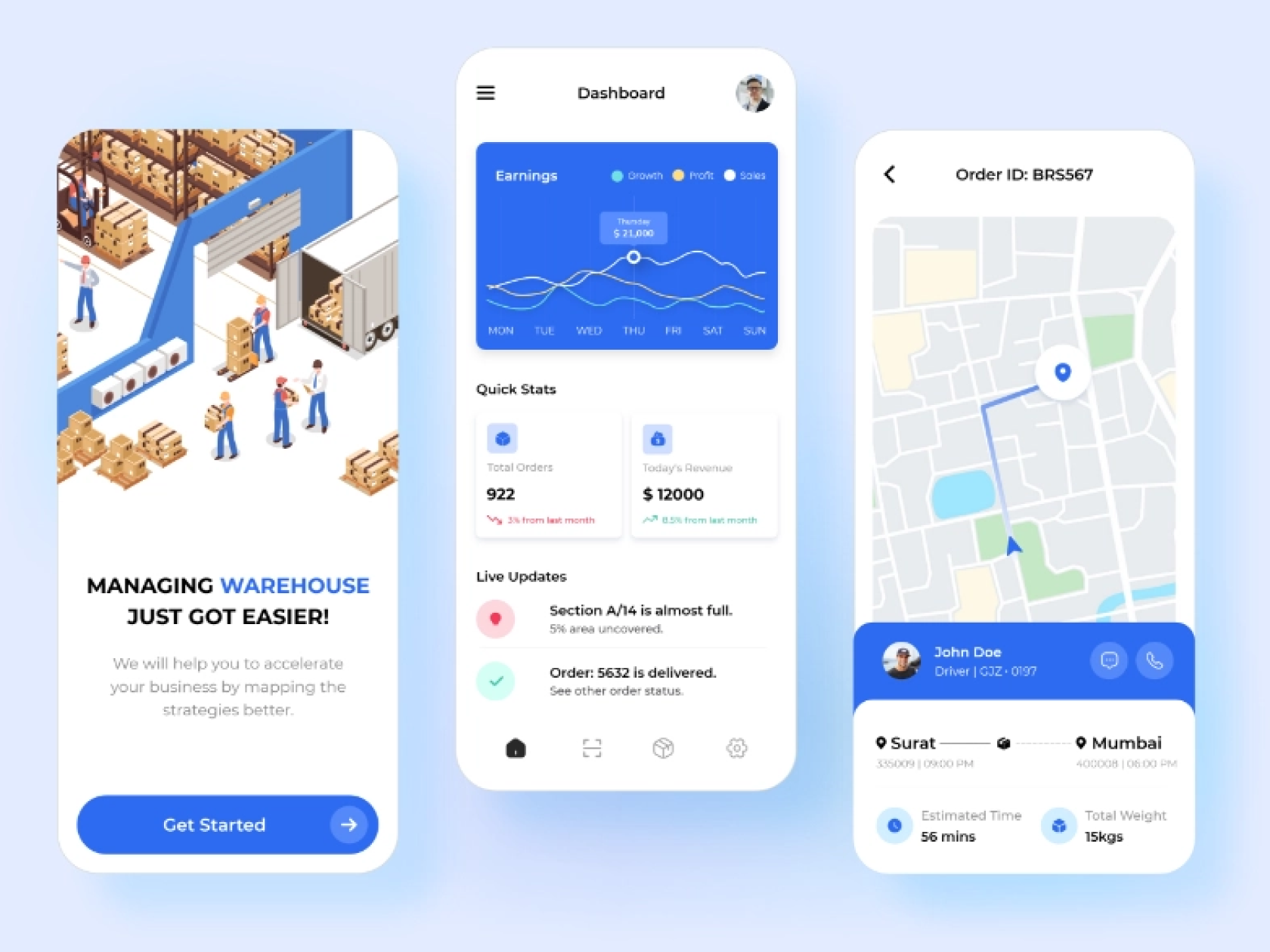

Warehouse automation employs tech, robotics, and software to boost efficiency in tasks once done manually. It encompasses automated storage, conveyors, robots, and management software. This tech integration refines inventory handling, minimizes errors, and quickens order processing. The aim is heightened efficiency, cost reduction, and catering to rising e-commerce and logistics demands.

How does warehouse automation work?

Warehouse automation uses tech and software to enhance operations. A WMS or ERP analyzes inventory and order data. Systems optimize storage, robots assist in item retrieval, and machine vision aids in product handling. Conveyors and vehicles move goods, while automation manages packing and labeling. Quality is checked via sensors, and prepared orders head to loading docks. This boosts efficiency, accuracy, and fulfillment speed.