Warehousing is not only convenient but also productive if the work is planned correctly. It is an essential part of a supply chain and affects many other areas of work. Warehouse management and the right approach to organizing processes will help you achieve better results and be more productive.

Since the warehouse plays an important role in logistics, you need to pay attention to its management, as well as to other processes that constitute day-to-day work, which takes a lot of time and effort. Let's look at how to properly organize work with a warehouse, how digital solutions can help here, and how to use robotics and automation in this process.

What Is Warehousing?

In logistics, warehousing is the activity of storing goods for further distribution or selling. This is a complex set of procedures that needs careful attention, but you may easily adjust it with the help of specialized software that simplifies work and helps to achieve greater accuracy and precision. Not only software but also robotics may help. With the proper approach, your warehouse may help you improve your performance. For large amounts of elaborate work, automation is the key.

Warehousing may sound simple, but if you run a big company, you definitely need a large space for storing goods, which only adds to the worries and duties in terms of management. With larger amounts of work come larger amounts of responsibilities, but managing even a large warehouse may be productive. There are tools that can assist you in making the processes easier and more organized.

Warehousing vs. Storage

There is a clear distinction between the process of warehousing and storage. While warehousing usually refers to the large-scale storing of items, the process of storage is mainly done on a smaller scale. It can also be done by companies that need to store goods for a short period of time.

In simple terms, warehousing is the process of storing large amounts of goods by logistics businesses, which is often complex and detailed. Warehousing requires renting or owning large spaces. It can also be used for bulky items. Storage is for smaller quantities of items and is less complex. It does not always require a lot of free space, but this process is intended for other purposes.

Warehouse Management System

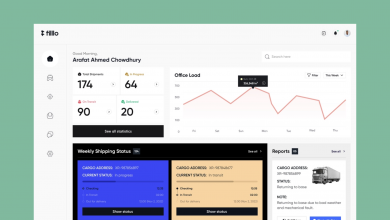

A warehouse management system is a special type of software intended to help simplify and automate the elaborate process of warehouse management. Since there are numerous minor details and processes that need to be considered, the software is what you need to get your job done. Also, keeping everything in one place is quite handy. Doing all the hard work by yourself would be ineffective and very time-consuming. Let’s have a look at how a warehouse management solution operates.

There are simple and complex warehouse management solutions, but they are centered around simplifying daily processes that constitute the work of a warehouse. WMS solutions are necessary for the control and management of inventory, but they also include a range of important tasks like analytics and various types of management.

Warehousing Logistics

The term warehouse logistics refers to everything that makes up the work of your warehouse, including processes, people, and software. As warehousing itself requires a lot of meticulous work, digital solutions are an essential part of this complex workflow.

Warehousing logistics are vital for organizing work and streamlining all the processes as it saves you a great deal of time and effort. This is especially important in the case of a large number of goods in the warehouse. Some of the additional benefits of quality warehouse logistics include reduced costs, which benefits the financial performance substantially, and faster delivery.

If we talk about the warehouse logistics itself, this process is aimed at optimizing the flow of items, as well as monitoring all the information and carefully fitting in time frames. In addition, it is necessary to work with aspects such as damaged items management and safety and security measures. Both of these issues significantly affect the process of warehouse management, as well as professional performance in general.

1. Warehouse Management

Every complex process in logistics requires a great deal of quality management. Warehousing is no exception. Basically, warehouse management includes all of the processes intended to make the warehouse work organized and streamlined. Since there are many processes involved, warehouse management is not an easy task.

In general, warehouse management is necessary for conducting and improving all of the daily processes in the warehouse. Some of the major tasks it includes are:

- inventory management;

- space organization;

- scheduling.

In order for everything to be in order, each of these processes must be controlled and connected to each other. Warehouse management works as a system with many important elements, so everything needs to be interconnected in order for the work to be effective. It's not easy, so technology can help here.

2. Warehouse Operations

The goal of all of the warehouse operations is to satisfy customers' needs and make the workflow consisting of the labor, space, and equipment, efficient and productive. Therefore, this process consists of numerous minor details that need attention and careful execution.

Warehouse operations include the areas like receiving, organization, and distribution processes. This aspect focuses on making the whole working process more productive. It requires a great deal of planning, organizing, and automating.

3. Warehouse Management Systems

There is specialized software that is aimed at making the process of warehousing simplified and more effective. Warehouse Management System (WMS) helps to streamline the processes within a warehouse and assists managers in inventory tracking. The larger the warehouse, the more important tasks, so a quality software solution is essential.

Some of the main features of a warehouse management system are:

- receiving goods;

- inventory management;

- picking and packing items;

- order management;

- labor management;

- analytics;

and so on. So, a warehouse management solution is not only helpful in terms of better inventory management, it has a number of valuable benefits for business owners that can make the whole workflow more productive. Generally, a warehouse management system covers a range of aspects from analytics to management, and is essential for automating processes. On a large scale, it is an irreplaceable digital assistant.

Benefits of a Warehouse Management System

Among the main benefits of a WMS, there are:

- a smaller number of returns;

- minimized operational expenses;

- better customer service;

- transparency and visibility;

Well-organized work is better in many ways, but it is especially important in terms of providing better customer service. With a WMS, you can improve your workflow and make your delivery faster, which is important for overall performance. Reduced operational expenses are an important factor for financial performance as it is hard to control such expenses on a large scale.

Warehousing and Your Supply Chain

Warehousing plays an important role in supply chain management. Also, your whole business strategy depends largely on the effective storage and management of items. Since warehousing also includes quality storage, the process of delivery becomes faster and more productive. Besides that, warehousing is also important for supply chains in terms of location and security. The location of your warehouse affects shipping, and the quality of item storage has an influence on potential item spoilage and delays in transportation processes.

Since warehousing can streamline the supply chain of your business in general, it definitely needs careful attention. The efficiency of your warehouse operations affects many other important processes and your business’ performance. The software can help you a lot in managing and organizing various processes within the warehouse, thus helping you to achieve better results.

How Robotics & Automation Can Help Your Business?

Automation may be exceptionally helpful in terms of a complex organization. Nowadays, there are plenty of robotic tools for warehouses that are gaining popularity in the transportation industry. Technologies like goods-to-person (G2P), articulated robotic arms, and automated guided vehicles (AGVs) have long been a popular tendency on the market.

But warehouse robotics is not just about robots. It is also software, which helps make work easier. When it comes to large amounts of work, the software is often essential for a productive workflow. Also, technologies can help save a lot of time and effort thus leading to higher employee satisfaction.

Conclusion

Since warehousing is a complex and important activity that encompasses many processes and tasks, automation and proper organization are required. This is why warehouse management needs specialized software and other tools to be effective.

Since the quality of storage of items is also extremely important, you can help yourself substantially by improving warehouse management and enhancing the quality of services. With better storage of goods, delivery also becomes better. Finally, how you store goods impacts your company’s work and the financial factor as well. By implementing warehouse management software, you can significantly reduce operational costs, which is beneficial for your company’s finances in general. So your work can be way better if you take the quality of your warehousing to the next level. As the market offers many solutions for automating and organizing work, you can rely on technology for improving your services.

Technology is in many ways much more accurate than human work, it helps to reduce the number of errors due to the human factor and to do much more work in a short time. It is the best tool for better management of your warehouse and improved work for your company. Help yourself achieve outstanding results by using technological tools.