Enterprise resource planning (ERP) systems have become an indispensable part of modern supply chain management. These comprehensive software solutions integrate various aspects of a company's operations, including finance, human resources, manufacturing, inventory management and customer relationship management, into a single unified system.

Now let's discuss the importance of ERP systems in more detail.

The Role of ERP in Supply Chain Management

Implementing an ERP system offers numerous benefits to supply chain management. From inventory management to supply solutions and production processes, there are various aspects to consider. ERP software allows businesses to gain real-time visibility into their operations, allowing them to assess current processes and identify areas that need improvement.

This article explores the advantages of ERP software in supply chain management, providing examples, statistics, and detailed explanations to illustrate its impact on businesses.

What Are the Benefits of Using ERP System in Supply Chain Management?

Demand planning and purchasing simplification are two of the most valuable benefits of ERP software. By better planning inventory needs, businesses can optimize multiple inventory levels and reduce overspending on stock by avoiding unnecessary purchases. By automating most of the purchasing process, businesses save time and increase productivity by making faster and more accurate decisions about purchasing.

Additionally, ERP enables documentation automation and processing, utilizing business intelligence applications for real-time data analysis and informed decision-making.

This includes automated generation and delivery of invoices and cross-border shipment documentation. Another advantage is the endless customization and 3rd party integrations offered by ERP systems, allowing tailoring to specific business needs and seamless integration with existing processes and systems.

Furthermore, ERP enhances customer service by enabling enhanced tracking and monitoring of customer concerns and improving communication and assistance across all customer contact channels. This can especially be seen in the case of automotive ERP software. Lastly, data security is prioritized with customizable ERP systems that offer flexibility while requiring adequate data encryption capabilities. Regular system patching is essential to mitigate security vulnerabilities and reduce data breaches.

Benefits of using ERP system in supply chain management include:

- Optimized inventory levels through better planning and forecasting.

- Reduced overspending on stock and manual order processing.

- Streamlined purchasing decisions with accurate and timely data.

- Documentation automation and processing through business intelligence applications.

- Automated generation and delivery of invoices and cross-border shipment documentation.

- Endless customization and 3rd party integrations for seamless integration with existing processes and systems.

- Enhanced tracking and monitoring of customer concerns.

- Improved communication and assistance across all customer contact channels.

How Does ERP Improve Supply Chain Management?

Understanding the principal role of ERP in supply chain management is vital for organizations. It provides total control and transparency by offering visibility into production processes, inventory management, and order fulfillment.

With real-time information and complete inventory transparency, businesses can make informed decisions. ERP also helps identify areas of improvement, such as cost reduction through inventory optimization and focusing on core products. It enhances customer service by streamlining processes and utilizing customer feedback.

Additionally, ERP improves inventory management by identifying depletion and avoiding understock or oversupply situations. Lastly, it contributes to better quality control through increased visibility and transparency. In addition to supply chain ERP, construction ERP systems are also an example of excellent quality control.

Principal role of ERP in supply chain management:

- Total control and transparency with visibility into production processes, inventory management, and order fulfillment.

- Informed decisions based on real-time information and complete inventory transparency.

- Areas of improvement: cost reduction through inventory optimization and focusing on core products.

- Enhanced customer service through streamlined processes and utilization of customer feedback.

- Improved inventory management by identifying depletion and avoiding understock or oversupply situations.

- Better quality control with increased visibility and transparency.

Our Tips for Successfully Integrating ERP Software into Your Supply Chain

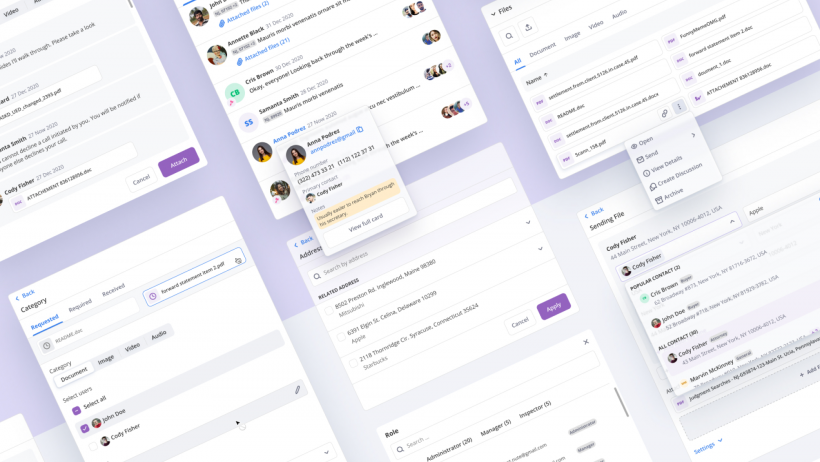

WEZOM has successful cases that highlight our expertise in creating a billing CMS system, and a workflow system for an energetic companies. Our team has experience in creating document management systems, CMS systems, and other robust software solutions that can simplify the management of your internal processes for better efficiency.

We have significant expertise when it comes to the different types of ERP systems and their benefits. Our tips for successfully integrating ERP software into your supply chain include:

- Define your objectives: Before beginning the ERP integration, clearly identify the goals and objectives of your project. This will help you stay focused throughout the process, and make better decisions as you go along.

- Conduct a thorough analysis: Before implementing the ERP software, conduct a comprehensive analysis of your existing supply chain processes. This will help you determine how the ERP system can be customized to meet your specific requirements.

- Choose the right ERP solution: Select an ERP software solution that aligns with your business needs and has robust supply chain management capabilities. Consider factors such as scalability, flexibility, integration capabilities, and industry-specific functionality.

- Engage stakeholders: Involve key stakeholders from various departments in the integration process, including supply chain, finance, procurement, and IT. Their input and collaboration will be crucial in ensuring a successful implementation.

- Plan for data migration: Develop a detailed plan for migrating data from your existing systems to the ERP software. Cleanse and validate data before the migration to avoid any issues or inconsistencies in the new system.

- Customize and configure: Work closely with the ERP vendor or implementation partner to customize and configure the software according to your supply chain processes and requirements. This may involve mapping workflows, defining roles and permissions, and configuring integrations with other systems.

- Provide comprehensive training: Conduct thorough training sessions for all users who will be interacting with the ERP system. This will help them understand how to use the software effectively and maximize its benefits. Consider providing ongoing training and support as needed.

- Test extensively: Prior to going live, conduct comprehensive testing of the ERP system to ensure that it functions as intended and integrates seamlessly with other systems. Test different scenarios and validate the accuracy of data and processes.

- Foster change management: Recognize that ERP integration represents a significant change for your organization. Invest in change management initiatives to ensure that employees understand the benefits of the new system, overcome resistance to change, and embrace the new process.

Custom ERP Software vs Packaged: How to Choose the Right System for Your Business?

When choosing an ERP solution for your business, it's essential to compare custom ERP software and packaged solutions to make an informed choice. To begin, you need to thoroughly understand the specific requirements of your business. This understanding will help streamline the selection process by identifying the features and functionalities that align with your unique needs.

Scalability is another important aspect to consider. As your business grows and evolves, your – even if we are talking about medical ERP systems – an ERP system should be able to accommodate increased user demands and data storage requirements. Ensure that the chosen ERP solution can scale effectively to support your long-term growth objectives.

Additionally, compatibility with your business needs is vital. Evaluate how well the ERP software integrates with your existing systems and processes, such as CRM, warehouse management, or inventory management. Seamless integration can streamline operations, reduce data duplication, and enhance overall efficiency.

By considering these factors and making a thorough comparison between custom ERP software and packaged solutions, you can make a well-informed choice that aligns with your business goals and maximizes the benefits of an ERP implementation.