Fuel prices are rising, while customers demand same-day delivery, and warehouses are often overloaded due to inaccurate demand forecasting – does this sound familiar? The problem is likely that you're still using Excel spreadsheets or other general-purpose software for planning. So, maybe it's time to start adopting the future of the logistics industry? Below, we’ll share with you the main logistics trends and insights.

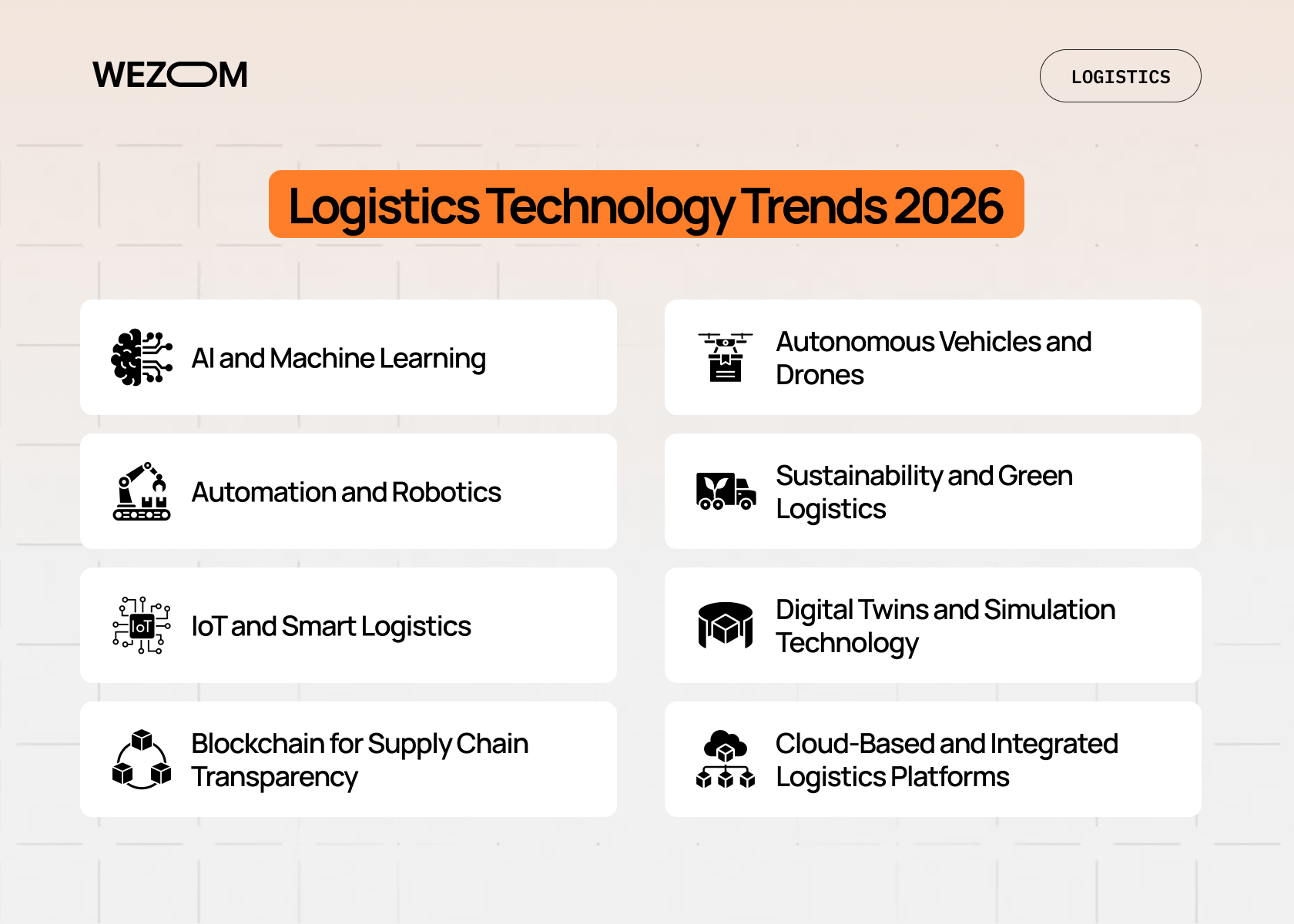

AI and Machine Learning in Logistics

As one of the main logistics trends, artificial intelligence has moved from the advisory stage to the autonomous dispatcher stage, radically changing the data management paradigm through the following capabilities.

Predictive analytics for demand and inventory

Machine learning algorithms are now capable of much more than simply providing historical sales analytics – they also take into account weather anomalies, market trends, competitor activity, and even socio-political events, ultimately reducing excess inventory costs by 15-20% and eliminating out-of-stock situations.

Route optimization and smart scheduling

AI systems can cope with smart, real-time routing, taking into account traffic jams, road construction, queues at terminals, and the individual driver's driving style. This allows logistics companies to achieve up to 25% savings on fuel costs and guarantee on-time delivery in 98%+ cases.

AI-driven warehouse management

AI algorithms can determine the most efficient storage areas for fast-selling goods, minimizing forklift mileage and predicting peak staff workloads. Therefore, systems based on them can optimize literally every centimeter of warehouse space and every second of working time.

Automation and Robotics

The modern market of new trends in logistics has been enriched with advanced automation and robotic solutions, accessible even to the SMB sector. These solutions enable logistics companies to achieve a precise performance schedule that, crucially, is unaffected by sick leave or shift changes, resulting in a 30-40% reduction in operating costs per order.

Warehouse automation: picking, sorting, packing

Modern automated storage and retrieval systems and high-speed sorters, unlike human operators, are capable of working 24/7 without downtime. For example, the use of modular automated lines increases order processing speed by 3-5 times while reducing packaging defects to near zero.

Autonomous forklifts and robotic assistants

These solutions don't require magnetic floor tape; instead, they use lidar and computer vision for navigation. They autonomously move pallets, avoiding obstacles and people, thereby maximizing safety and reducing reliance on human personnel.

Internet of Things (IoT) and Smart Logistics

Modern IoT solutions, representing the logistics of the future, are capable of providing end-to-end visibility into every stage of the supply chain.

Sensors for real-time tracking and monitoring

Modern IoT sensors monitor cargo location via GPS, tracking temperature, humidity, light levels, impact force during loading, and more. This can be critical for pharmaceuticals and food products, where even a 10-minute delay can result in millions of dollars in lost inventory.

Fleet telematics and connected vehicles

Connected vehicles can transmit hundreds of parameters to the cloud, including brake pad wear, fuel consumption, and more, which ultimately allows logistics operators to move toward predictive maintenance, detecting potential breakdowns before they occur.

Smart supply chains and visibility

IoT integration allows all supply chain participants, from manufacturers to customers, to monitor product movement in a single dashboard, reducing the administrative burden on human staff and enabling immediate reaction to delays in the delivery process.

Blockchain for Supply Chain Transparency

In the context of logistics market trends, blockchain can serve as a single, immutable source of truth, as opposed to traditional paper waybills, which are easily forged or lost. This ensures comprehensive transparency between all supply chain participants.

Traceability and authenticity of goods

Blockchain allows you to create an immutable digital trace of every product, whether it's raw materials at a factory or finished product packaging. For manufacturers, this solves the problem of counterfeiting and enables instant confirmation of product origin. Furthermore, if a defective batch needs to be recalled, the blockchain system reduces the time it takes to find the problem node from weeks to seconds.

Smart contracts for automated transactions

Smart contracts are code that automatically executes transactions or closes deals when certain conditions are met. Using them, you can minimize the number of intermediaries, as well as eliminate unnecessary bureaucracy and payment delays, thereby reducing administrative costs by 30-70%.

Autonomous Vehicles and Drones

In global logistics, unmanned technologies, despite the mandatory certification by local legislation, are actively used for the transportation of goods not only in closed locations.

Self-driving trucks for long-haul logistics

Level-4 autonomous trucks are typically used on dedicated freight corridors, reducing delivery times by 30-40% due to their ability to operate 24/7 without interruption. They also seamlessly integrate with the TMS, allowing a single dispatcher to centrally manage an entire fleet of trucks.

Drone deliveries for last-mile solutions

Since last-mile delivery is the most expensive and difficult stage of the supply chain, logistics companies are increasingly turning to drones, which can easily bypass traffic jams, ultimately reducing the cost of final delivery by up to 50%.

Sustainability and Green Logistics

Sustainability, especially in the logistics sector, is no longer a marketing ploy but a mandatory regulatory requirement in many countries.

Energy-efficient warehouses and vehicles

Logistics hubs are increasingly using solar panels and energy recovery systems in conveyors. Companies also switch to electric and hydrogen trucks, whose long-term TCO is 15% lower than that of diesel alternatives due to subsidies and lower maintenance costs.

Carbon tracking and reporting technologies

The introduction of digital product passports obliges companies to regularly report their CO2 emissions. That’s why they deploy specialized IT platforms that automatically calculate the carbon footprint of each delivery, enabling them to choose the greenest routes.

Circular supply chains and eco-friendly innovations

Circular supply chains, as one of the hottest logistics technology trends, ensure efficient management of reverse logistics (i.e., returns) and packaging recycling, enabling resource reuse. This reduces raw material costs and minimizes waste.

Digital Twins and Simulation Technology

Using digital twins in connectivity with AI makes it possible to create automated, proactive systems that, in addition to notifying about problems, also instantly suggest solutions, calculating the costs and risks associated with each of them.

Modeling supply chain operations

While being one of the current trends in supply chain management, digital twins can represent virtual, real-time copies of warehouses, ports, or entire logistics networks. For example, if a delivery delay occurs, they can provide operators with a full picture of how this will impact existing inventory over a fixed period of time.

Testing scenarios for optimization

By running simulations, digital twins can show you what will happen if you close a specific warehouse or, for example, if demand for a certain product group increases by 50%. This allows you to choose optimal scenarios that will save you thousands or even millions of dollars before they're even implemented.

Cloud-Based and Integrated Logistics Platforms

Seamless integration and cloud hosting make your data and services accessible from any device and location with an internet connection.

ERP and TMS software solutions

Warehouse software like WMS shouldn't exist autonomously from your TMS and ERP systems – that's why it makes sense to choose cloud solutions that offer seamless integration. This allows you to achieve end-to-end automation of workflows, for example, a customer order, once it appears in the CRM, can automatically reserve the product in the warehouse, plan the route in the TMS, and generate a financial forecast in the ERP.

Data-driven decision making

The cloud allows you to analyze big data in real time, so your department managers can check route margin deviations, monitor the drivers’ efficiency, or track the likelihood of missed delivery dates.

Collaboration and system integration

Cloud platforms allow you to connect external contractors, carriers, and brokers to your IT infrastructure via secure APIs, providing all participants with a single source of truth in real time.

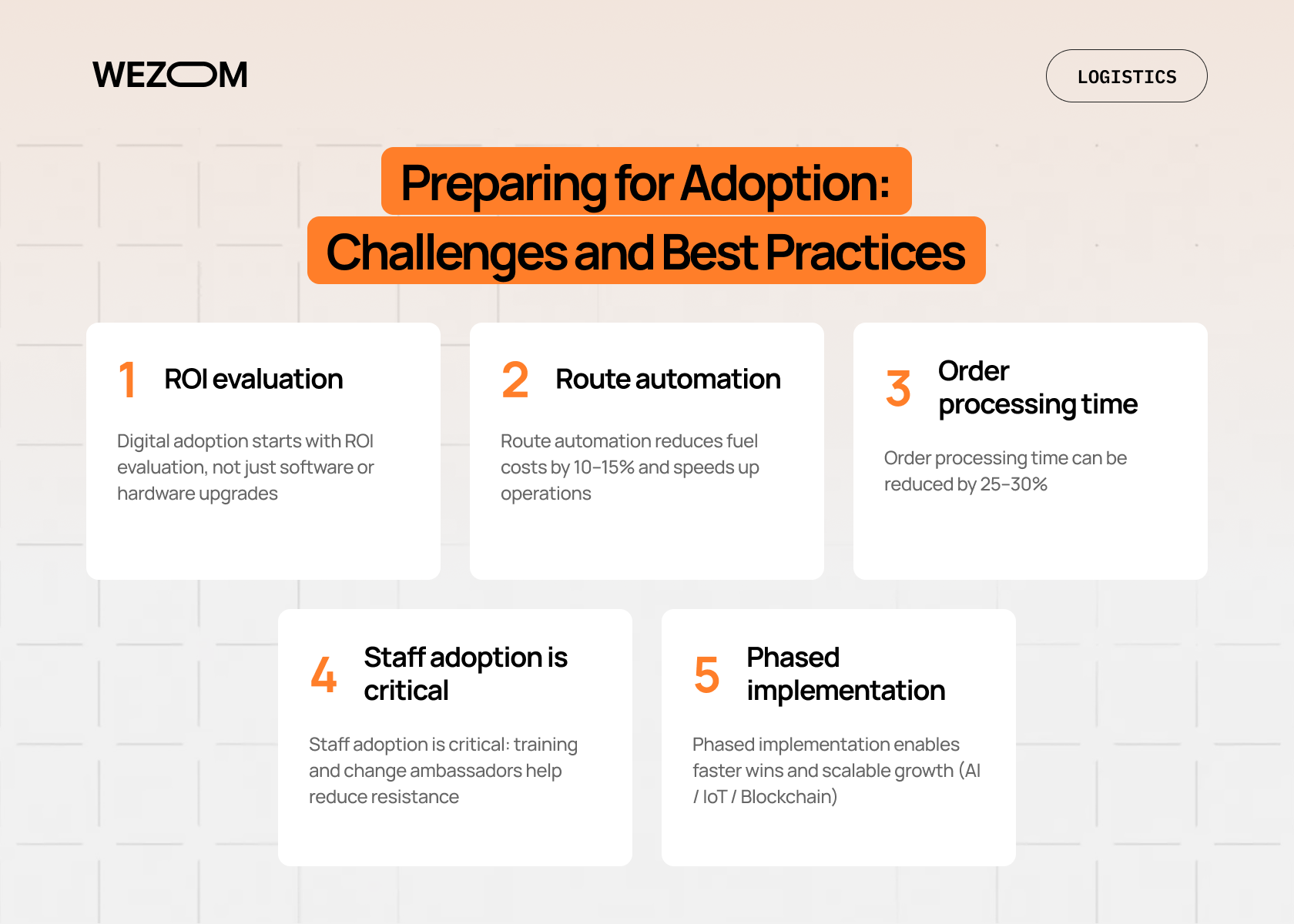

Preparing for Adoption: Challenges and Best Practices

Each business’ digitization involves much more than upgrading software and hardware – it begins with assessing the ROI of the adopted trends in transportation and logistics. Specifically, while the initial costs may seem significant, they pay for themselves through route automation (which, in turn, reduces fuel budgets by 10-15%), minimization of order processing time (by 25-30%), and more. Generally, with thoughtful implementation, ROI is achieved within the first 12-18 months.

At the same time, it's important to understand that you may encounter staff resistance to new software or hardware, which is why it's crucial to train them to work in new ways, appointing change ambassadors within departments and implementing the technologies described above in stages rather than all at once. That is, it's better to start with the most important node, whether it's delivery transparency or warehouse accounting – this way, you’ll be able to scale the core cloud infrastructure, adding modules with AI/IoT/blockchain or any other innovations as soon as your employees learn how to deal with them.

If you would like to start your company’s digital transformation and are looking for a reliable logtech partner, feel free to write or call us!

FAQ

What are the top logistics technology trends for 2026?

The key trends in the logistics industry include fully autonomous AI agents and robots, end-to-end blockchain and IoT-based solutions, and green logistics.

How does cloud technology impact logistics management?

The cloud provides mobility and scalability, allowing operators to manage a global warehouse network from a standard tablet.

How is AI transforming supply chain management?

Being one of the most promising logistics industry trends, AI accurately predicts consumer demand, automatically reroutes shipments during traffic jams, independently selects suppliers based on reliability ratings, and more.

What role does robotics play in modern warehouses?

Robotics ensures error-free packaging and optimization of the use of warehouse space through denser storage, while working 3–4 times faster than humans.

How can IoT improve logistics operations?

IoT sensors monitor cargo safety in real time, preventing its damage, while fleet telematics helps save fuel and predict equipment breakdowns, eliminating long downtime on the road.