Warehouse Management Systems

What is Warehouse Management Systems

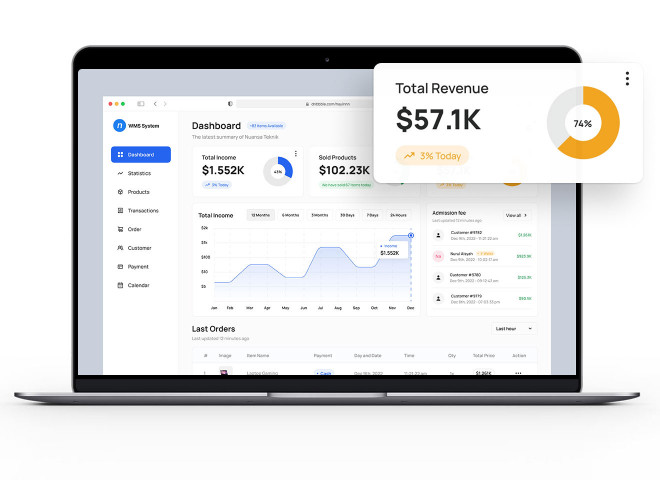

Warehouse management systems software is a solution that provides an overview of a company's inventory and enables order fulfillment management at all stages of a supply chain, from the distribution center to the store shelf.

Increasing the speed of order fulfillment

WMS allows your team to use mobile terminals to automate manual operations so orders can be picked and packed faster, reducing processing and shipping times.

Error minimization

WMS initiates all personnel activity, in case of incorrect operations, for example, scanning another product, it warns of an erroneous action and keeps records of the cargo in real-time.

Time-saving

A warehouse management system reduces the time of operations, especially for the assembly and delivery of orders. Inventory of freights is also carried out faster, without errors, and stopping the work process.

We've Been Awarded Plenty for the Milestones We Have Achieved

What clients say

We chose WEZOM amongst other companies because they provided prototypes of future systems and we had a clear understanding of what the finished product would look like. We worked with the team on several projects, including the development of a CRM with adaptation for desktop and mobile versions, as well as the creation of a suite of server applications that are available on iOS, Android, and online. We are very pleased with the results and the flexibility of the WEZOM team.

I am very satisfied wit the work process and project management. Everything was clear, on time and I had nothing specific to add. Yes, we are satisfied with the result of the work and the product meets the goals set. I can't wait to continue our work on the app.

Thanks to WEZOM, our sales increased by 65% and conversions increased by 150%. The team fully developed an online store for us, with 1C and amoCRM integrations. The guys conducted a market analysis, created a mind map with all the functions of the future site, and argued for each element of development. Everything was transparent, and the quality was high.

Questions & Answers

What does a warehouse management system do?

Warehouse management system software helps ensure that all the goods are moved through warehouses in the most effective way. With the help of warehouse management software systems, you can optimize the movements of goods and all the additional operations and make them cost-effective. A warehouse management system handles many aspects related to goods, including processes like tracking, receiving, and picking.

Are warehouse management systems secure?

Although generally, a WMS system can provide you with a sufficient level of security, usually, no visibility on why an item may be returned is included. Also, among the challenges of using these solutions, there is inaccurate information regarding inventory and improper labor management. Some of the best WMS systems are totally secure, but you need to choose a solution that can fully cover your needs.

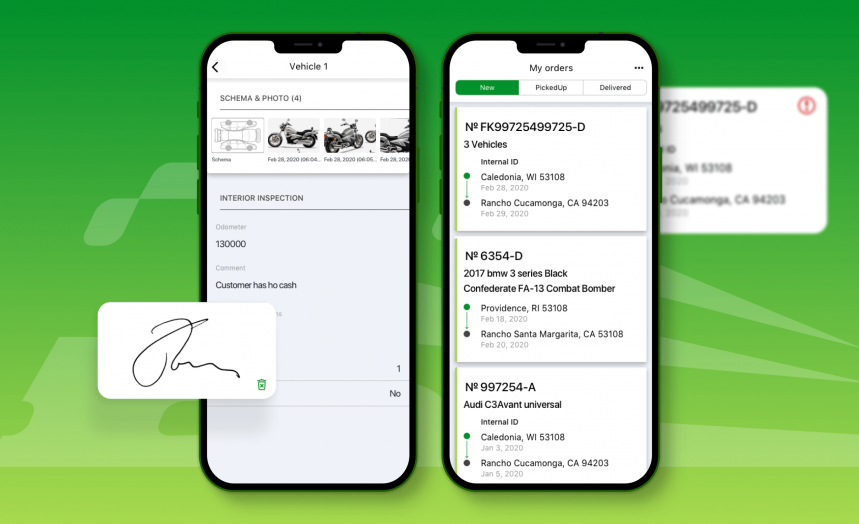

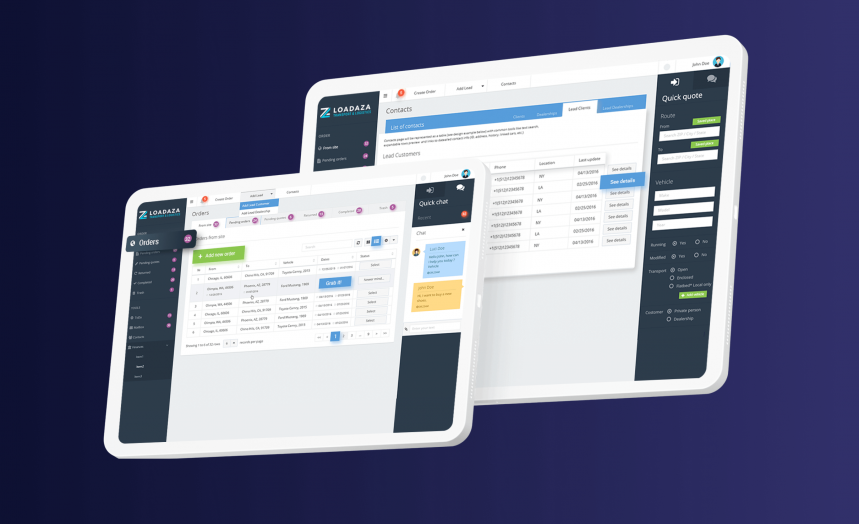

Efficient Warehouse Management Systems for Your Business

At WEZOM, we offer customizable Warehouse Management Systems that can help you streamline your warehouse operations. Our solutions include real-time inventory tracking, barcode scanning, and order fulfillment, allowing you to manage your warehouse with ease and precision.

Our user-friendly software is designed to be integrated seamlessly into your existing workflows. Whether you're a small business or a large enterprise, we can help you optimize your warehouse operations and stay ahead of the competition.

Get the Best Customizable Warehouse Management Solutions

Our experienced team of experts is committed to providing exceptional service and support to our clients. Contact us today to learn more about our Warehouse Management Systems and how they can help you take your business to the next level.